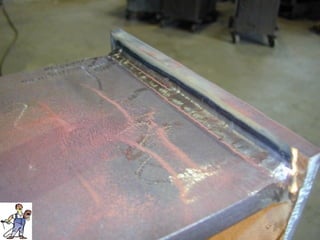

- Lamellar tearing is commonly observed discontinuity in fusion welding that occurs near the heat-affected zone in flange plates of T-butt joints. It is caused by factors like dilution and heat input during welding.

- Dilution is affected by the melted parent metal, melted filler metal, and weld width to depth ratio. Too low or too high heat input can both be detrimental.

- Solidification cracks can form due to the bead factor, which is the ratio of weld width to depth. A ratio greater than 1 or less than 1 can both result in cracks.

![Preheat Temp. for C & C-Mn Steel only:Preheat Temp. for C & C-Mn Steel only:

00

F = 1,000 (C% - 0.11) + 18 t"F = 1,000 (C% - 0.11) + 18 t"

Where C% is only up to 0.65% max.Where C% is only up to 0.65% max.

A Saiferian formula for preheat to prevent cold cracks;A Saiferian formula for preheat to prevent cold cracks;

00

C =C = 350350 [C][C]ee - 0.25- 0.25

[C][C]ee== [C][C]cc ++ [C][C]tt

[C][C]cc = C% + + += C% + + +

(Mn + Cr)%(Mn + Cr)%

99

Ni%Ni%

1818

7Mo%7Mo%

9090

[C][C]tt = [C]= [C]cc X 0.005 tX 0.005 t

t = Thickness in mmt = Thickness in mm](https://image.slidesharecdn.com/weldingflaws-140723105609-phpapp01/85/Welding-flaws-27-320.jpg)