Radiographic interpretation

•

35 likes•26,431 views

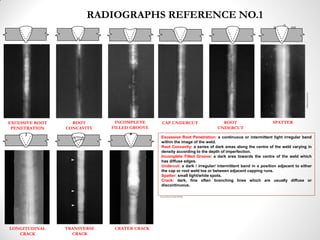

This document provides definitions for various defects that may appear on radiographic images of welds, including: - Excessive root penetration appears as a light irregular band within the weld image. - Root concavity appears as dark areas along the weld center varying in density by imperfection depth. - Incomplete filled groove appears as a dark area at the weld center with diffuse edges. - Cracks appear as dark, fine lines that are usually diffuse or discontinuous.

Report

Share

Report

Share

Download to read offline

Recommended

radiographer-s-weld-interpretation-reference

The document provides descriptions of common welding defects along with their corresponding radiographic images. It describes 14 different types of defects including misalignments, lack of penetration, inclusions, cracks, and more. Each defect entry explains what it is, such as offset or mismatch being a misalignment of pieces to be welded, and describes its radiographic image appearance, such as an abrupt change in film density across the weld image width. In total, it covers 14 common welding defects and their radiographic signatures for non-destructive testing interpretation.

Weld defects 1

The document discusses the benefits of exercise for mental health. Regular physical activity can help reduce anxiety and depression and improve mood and cognitive functioning. Exercise has also been shown to increase gray matter volume in the brain and reduce risks for conditions like Alzheimer's and dementia.

Radiographic poster

The document describes various visual indications that may appear on radiographic images of welds, including irregular densities, darker spots, lines, and changes in density. It also provides information on different radiographic testing methods, such as single wall single image, double wall single image, and double wall double image techniques. Acceptance criteria and standards for radiography from ASME and API are also mentioned.

Rtfi weld defects[1]![Rtfi weld defects[1]](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![Rtfi weld defects[1]](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

This document discusses artifacts that may appear on radiographic films. It defines several types of artifacts including burned film, chemical stains, crimp marks, lead foil scratches, light leaks, pressure marks, sand/dirt marks, scratch marks, static marks, water marks, and roller marks from automatic processing. For each artifact, it provides an example radiographic image and brief description of how the artifact is caused. The purpose is to help trainees identify and understand artifacts that could affect the interpretation of radiographic images.

radiographic-interpretation.pdf

The document is a training manual on radiographic interpretation of welds. It contains multiple radiographic images of welds with defects labeled, asking the reader to identify the defects shown. The defects illustrated include lack of root penetration, porosity, undercutting, cracking, incomplete fusion, excess penetration, spatter, slag inclusions and others. The purpose is to help trainees learn to identify various weld defects from radiographic images.

Rt acceptance criteria by zas

1. The document compares acceptance criteria for radiographic testing of welds according to various industry codes and standards. It lists types of defects such as cracks, incomplete penetration, and burn through.

2. Defect sizes are evaluated based on factors like weld thickness, density compared to base metal, length, and distance between defects. Some defects are unacceptable when they exceed certain sizes.

3. Charts are provided to evaluate the acceptability of rounded indications based on weld thickness and isolation from other defects. Clustered defects have stricter criteria than random defects.

Welding defects

The document discusses the results of a study on the impact of COVID-19 lockdowns on air pollution. Researchers analyzed data from dozens of countries and found that lockdowns led to an average decline of nearly 30% in nitrogen dioxide levels over cities. However, they also observed that this improvement was temporary and air pollution rebounded once lockdown restrictions began lifting. Overall, the study highlights how human activities are a major driver of air pollution but also that systemic changes are needed for long-term air quality improvements.

Recommended

radiographer-s-weld-interpretation-reference

The document provides descriptions of common welding defects along with their corresponding radiographic images. It describes 14 different types of defects including misalignments, lack of penetration, inclusions, cracks, and more. Each defect entry explains what it is, such as offset or mismatch being a misalignment of pieces to be welded, and describes its radiographic image appearance, such as an abrupt change in film density across the weld image width. In total, it covers 14 common welding defects and their radiographic signatures for non-destructive testing interpretation.

Weld defects 1

The document discusses the benefits of exercise for mental health. Regular physical activity can help reduce anxiety and depression and improve mood and cognitive functioning. Exercise has also been shown to increase gray matter volume in the brain and reduce risks for conditions like Alzheimer's and dementia.

Radiographic poster

The document describes various visual indications that may appear on radiographic images of welds, including irregular densities, darker spots, lines, and changes in density. It also provides information on different radiographic testing methods, such as single wall single image, double wall single image, and double wall double image techniques. Acceptance criteria and standards for radiography from ASME and API are also mentioned.

Rtfi weld defects[1]![Rtfi weld defects[1]](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![Rtfi weld defects[1]](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

This document discusses artifacts that may appear on radiographic films. It defines several types of artifacts including burned film, chemical stains, crimp marks, lead foil scratches, light leaks, pressure marks, sand/dirt marks, scratch marks, static marks, water marks, and roller marks from automatic processing. For each artifact, it provides an example radiographic image and brief description of how the artifact is caused. The purpose is to help trainees identify and understand artifacts that could affect the interpretation of radiographic images.

radiographic-interpretation.pdf

The document is a training manual on radiographic interpretation of welds. It contains multiple radiographic images of welds with defects labeled, asking the reader to identify the defects shown. The defects illustrated include lack of root penetration, porosity, undercutting, cracking, incomplete fusion, excess penetration, spatter, slag inclusions and others. The purpose is to help trainees learn to identify various weld defects from radiographic images.

Rt acceptance criteria by zas

1. The document compares acceptance criteria for radiographic testing of welds according to various industry codes and standards. It lists types of defects such as cracks, incomplete penetration, and burn through.

2. Defect sizes are evaluated based on factors like weld thickness, density compared to base metal, length, and distance between defects. Some defects are unacceptable when they exceed certain sizes.

3. Charts are provided to evaluate the acceptability of rounded indications based on weld thickness and isolation from other defects. Clustered defects have stricter criteria than random defects.

Welding defects

The document discusses the results of a study on the impact of COVID-19 lockdowns on air pollution. Researchers analyzed data from dozens of countries and found that lockdowns led to an average decline of nearly 30% in nitrogen dioxide levels over cities. However, they also observed that this improvement was temporary and air pollution rebounded once lockdown restrictions began lifting. Overall, the study highlights how human activities are a major driver of air pollution but also that systemic changes are needed for long-term air quality improvements.

Twi cswip welding inspection notes and questions

The document discusses the duties of a welding inspector, including visual inspection of welds to identify defects and ensure they meet acceptance criteria. It describes tools that can aid inspection like magnification lenses. It outlines a code of practice for an inspection department, including checking documents, materials, equipment and welder qualifications before welding, monitoring the welding process and variables during welding, and inspecting the final weld for defects, dimensions and heat treatment after welding. Repairs should follow an authorized procedure and be re-inspected upon completion.

Geit 10017 en-weldinspection rt interpretation-22-25

This document provides a reference guide for radiographers to interpret welds. It contains descriptions and examples of various types of discontinuities that can be detected in radiographic images of welds, including mismatches, lack of penetration, inclusions, cracks, porosity, and other defects. The guide defines each discontinuity type and provides details on their visual appearance on radiographs to aid in identification.

Welding Defects

I used this to train QA/QC Engineers in Asia, what defects are and the possible effects they can have on the finished products.

Welding defects

This document provides a classification and overview of common welding defects. It divides defects into three main categories: planar defects, linear volumetric defects, and non-planar defects. Examples of each type of defect are given. The document also describes specific defect types such as cracks, inclusions, lack of fusion, porosity, overlap, undercut and provides potential causes of each.

Weld Defects

This document discusses various types of welding defects and imperfections including lack of fusion, porosity, slag inclusions, and solidification cracking. It describes how to identify each type, their causes, best practices for prevention, acceptance standards, and methods for detection and remediation. The key types of imperfections are classified as fabrication defects occurring during welding or service defects that form during use, and guidelines are provided for minimizing defects and producing quality welds.

RT Acceptance criteria

Radiography acceptance criteria For ASME B31.3, B31.1, API 650, ASME Sec Viii , ASME Sec iX

Presentation on common weld dicontinuities

The document discusses various common weld discontinuities and defects such as gas pores, slag inclusions, incomplete penetration, lack of fusion, cracks, and undercut. It describes the causes of these defects which can include trapped gas during solidification, contaminated base metal, improper welding parameters, and faulty joint preparation. Remedies suggested to avoid defects are ensuring adequate shielding from wind, using clean electrodes, maintaining the proper arc length, travel speed, and current level.

Asme section ii c new

The document outlines the sections and subsections contained in the ASME Boiler and Pressure Vessel Code. It includes rules for construction of various types of boilers, pressure vessels, and containment systems. The sections cover materials specifications, welding requirements, nondestructive testing, in-service inspection, and rules for ongoing care and operation. The code also provides alternative rules for special construction applications.

Welders visual inspection_handbook-2013_web

This document provides a handbook for visual inspection of welds. It includes sections on visual inspection responsibilities and techniques, definitions and images of common weld defects such as cracks, underfill, burn through, incomplete fusion, roughness, overlap, undersized fillets, incomplete penetration, undercut, corner melt, and end melt. Preventive and corrective actions are provided for each defect. The handbook also includes sections on measuring fillet weld size, types of weld joints, parts of a weld, welding symbols and joint numbering systems. It is intended to provide basic information for visual inspection of welds and is not a replacement for work procedures or other technical documents.

criteria of weld defects

The document discusses weld defect acceptance criteria according to different codes such as ASTM B31.1, ASME VIII, ASME B31.3, and AWS D1.1. It provides details on acceptance limits for various weld defects depending on the examination method, material thickness, loading conditions, and material application. Defects discussed include cracks, lack of fusion, incomplete penetration, undercuts, porosity, and reinforcement. Acceptance criteria include maximum defect sizes, numbers of defects allowed, cumulative lengths of defects, and distances between defects.

pdfslide.net_120174253-twi-radiographic-interpretation-weld-defects-repair.pdf

This document provides information on welding defects that can be detected through visual inspection. It discusses various types of defects like cracks, inclusions, lack of fusion, porosity issues, profile irregularities, and more. For each defect type, it describes possible causes and examples. It also covers defects in welded joints and repairs. In summary, the document is a reference manual on visual welding defects, their classification, potential causes, and repair considerations.

ASNT Radiographic Film Interpretation (RTFI) Notes-Dr. Samir Saad

The document discusses the history and impact of climate change over the past century. It notes that global temperatures and sea levels have risen significantly, with extreme weather events like hurricanes also increasing. The causes are attributed to human activities like burning fossil fuels that release greenhouse gases and trap heat in the lower atmosphere. Major impacts are expected to continue and worsen if emissions are not reduced substantially in the coming decades.

Welding flaws

- Lamellar tearing is commonly observed discontinuity in fusion welding that occurs near the heat-affected zone in flange plates of T-butt joints. It is caused by factors like dilution and heat input during welding.

- Dilution is affected by the melted parent metal, melted filler metal, and weld width to depth ratio. Too low or too high heat input can both be detrimental.

- Solidification cracks can form due to the bead factor, which is the ratio of weld width to depth. A ratio greater than 1 or less than 1 can both result in cracks.

Aws d1.1 guides

This document provides guidelines for essential variables that determine the qualification range of a welding procedure specification in accordance with AWS D1.1 Structural Welding Code - Steel. It summarizes the qualification ranges for position, thickness/diameter, base metal selection, preheat requirements, joint details, heat input, and welding processes. The guidelines specify the testing parameters and qualified ranges for groove welds, fillet welds, plate and pipe configurations.

ASME SEC IX PPT.pdf

The document summarizes the key aspects of ASME Section IX (Ed. 2019), which contains requirements for welding procedure and performance qualifications. It discusses the history and timeline of ASME standards development. It also provides an overview of the various articles within ASME Section IX, including Article I on general welding requirements, Article II on welding procedure qualification, Article III on welding performance qualification, and Article IV on welding data. Key terms like essential variables, P-numbers, F-numbers, and A-numbers used for material grouping are also defined in the document.

Asme sec ix overview

This document provides an introduction to ASME Section IX, which establishes general guidelines for welding procedure and welder performance qualifications. It discusses the requirements for qualifying welding procedures using procedure qualification records (PQRs) and welding procedure specifications (WPSs). The key points covered include:

- ASME Section IX covers the qualification of welding and brazing procedures.

- Welding procedure qualifications demonstrate that a set of welding variables can reliably produce sound welds.

- WPSs and PQRs are used to document and qualify welding procedures. A WPS must be supported by a qualified PQR to be used for production.

It also summarizes the classification of base metals using 'P' numbers,

Wis5 welding defects 02

The document discusses various welding defects that can be visually detected, including cracks, lack of solid metal, lack of fusion, lack of smoothly blended surfaces, and miscellaneous defects. It provides details on different types of each defect, their causes, and methods for prevention. It also discusses welding repairs, noting that repairs require authorization and testing to ensure defects have been fully removed before performing the repair weld.

How to Qualify a Welding Procedure

The document outlines the five step process to qualify a welding procedure according to ASME Section IX. It provides details on developing a draft procedure using 0.75" A36 steel plate welded in the flat position using GTAW and GMAW. Variables such as joint design, base metal and thickness, filler metal type and size, welding position, and electrical parameters are documented. The qualification weld was tested to verify it results in an acceptable weld with proper mechanical properties before the welding procedure specification can be used in construction.

Welding of Similar & dissimilar - Metal filler chart

Welding technology

This chart shows Specification of filler wire while welding Similar & Dissimilar metals

How to produce PQR

This document outlines the 8 steps to produce a Procedure Qualification Record (PQR) according to the ASME Section IX code. The steps are: 1) identify essential variables for the welding process, 2) add remaining essential variables from construction codes, 3) fill out the PQR format, 4) choose a qualified welder, 5) record welding parameters, 6) perform visual and mechanical tests, 7) record test results on the PQR, and 8) sign and date the completed PQR.

Rt Acceptance

The document provides acceptance criteria for various types of defects found during radiographic testing of welds based on different codes and standards including API 1104, SP-1174, B31.3, and ASME Section IX. It lists the maximum allowable size, length, and aggregate length of defects such as cracks, incomplete penetration, incomplete fusion, burn through, slag inclusions, porosity, and undercutting.

Radiographic interpretation

This document provides an overview of radiographic interpretation for periapical and panoramic dental x-rays. It defines dental radiography and describes the main intraoral and extraoral views. Periapical radiographs show the entire tooth and surrounding structures, and are useful for detecting dental issues like caries, periapical pathology, implants and more. Panoramic radiographs provide a wide view of the jaws and are used to assess issues like gross caries, fractures, cysts and tumors. The document outlines the normal radiographic anatomy seen in these views and provides guidance on interpreting radiographs through steps like localization, observation, interpretation and correlation to arrive at a diagnosis.

More Related Content

What's hot

Twi cswip welding inspection notes and questions

The document discusses the duties of a welding inspector, including visual inspection of welds to identify defects and ensure they meet acceptance criteria. It describes tools that can aid inspection like magnification lenses. It outlines a code of practice for an inspection department, including checking documents, materials, equipment and welder qualifications before welding, monitoring the welding process and variables during welding, and inspecting the final weld for defects, dimensions and heat treatment after welding. Repairs should follow an authorized procedure and be re-inspected upon completion.

Geit 10017 en-weldinspection rt interpretation-22-25

This document provides a reference guide for radiographers to interpret welds. It contains descriptions and examples of various types of discontinuities that can be detected in radiographic images of welds, including mismatches, lack of penetration, inclusions, cracks, porosity, and other defects. The guide defines each discontinuity type and provides details on their visual appearance on radiographs to aid in identification.

Welding Defects

I used this to train QA/QC Engineers in Asia, what defects are and the possible effects they can have on the finished products.

Welding defects

This document provides a classification and overview of common welding defects. It divides defects into three main categories: planar defects, linear volumetric defects, and non-planar defects. Examples of each type of defect are given. The document also describes specific defect types such as cracks, inclusions, lack of fusion, porosity, overlap, undercut and provides potential causes of each.

Weld Defects

This document discusses various types of welding defects and imperfections including lack of fusion, porosity, slag inclusions, and solidification cracking. It describes how to identify each type, their causes, best practices for prevention, acceptance standards, and methods for detection and remediation. The key types of imperfections are classified as fabrication defects occurring during welding or service defects that form during use, and guidelines are provided for minimizing defects and producing quality welds.

RT Acceptance criteria

Radiography acceptance criteria For ASME B31.3, B31.1, API 650, ASME Sec Viii , ASME Sec iX

Presentation on common weld dicontinuities

The document discusses various common weld discontinuities and defects such as gas pores, slag inclusions, incomplete penetration, lack of fusion, cracks, and undercut. It describes the causes of these defects which can include trapped gas during solidification, contaminated base metal, improper welding parameters, and faulty joint preparation. Remedies suggested to avoid defects are ensuring adequate shielding from wind, using clean electrodes, maintaining the proper arc length, travel speed, and current level.

Asme section ii c new

The document outlines the sections and subsections contained in the ASME Boiler and Pressure Vessel Code. It includes rules for construction of various types of boilers, pressure vessels, and containment systems. The sections cover materials specifications, welding requirements, nondestructive testing, in-service inspection, and rules for ongoing care and operation. The code also provides alternative rules for special construction applications.

Welders visual inspection_handbook-2013_web

This document provides a handbook for visual inspection of welds. It includes sections on visual inspection responsibilities and techniques, definitions and images of common weld defects such as cracks, underfill, burn through, incomplete fusion, roughness, overlap, undersized fillets, incomplete penetration, undercut, corner melt, and end melt. Preventive and corrective actions are provided for each defect. The handbook also includes sections on measuring fillet weld size, types of weld joints, parts of a weld, welding symbols and joint numbering systems. It is intended to provide basic information for visual inspection of welds and is not a replacement for work procedures or other technical documents.

criteria of weld defects

The document discusses weld defect acceptance criteria according to different codes such as ASTM B31.1, ASME VIII, ASME B31.3, and AWS D1.1. It provides details on acceptance limits for various weld defects depending on the examination method, material thickness, loading conditions, and material application. Defects discussed include cracks, lack of fusion, incomplete penetration, undercuts, porosity, and reinforcement. Acceptance criteria include maximum defect sizes, numbers of defects allowed, cumulative lengths of defects, and distances between defects.

pdfslide.net_120174253-twi-radiographic-interpretation-weld-defects-repair.pdf

This document provides information on welding defects that can be detected through visual inspection. It discusses various types of defects like cracks, inclusions, lack of fusion, porosity issues, profile irregularities, and more. For each defect type, it describes possible causes and examples. It also covers defects in welded joints and repairs. In summary, the document is a reference manual on visual welding defects, their classification, potential causes, and repair considerations.

ASNT Radiographic Film Interpretation (RTFI) Notes-Dr. Samir Saad

The document discusses the history and impact of climate change over the past century. It notes that global temperatures and sea levels have risen significantly, with extreme weather events like hurricanes also increasing. The causes are attributed to human activities like burning fossil fuels that release greenhouse gases and trap heat in the lower atmosphere. Major impacts are expected to continue and worsen if emissions are not reduced substantially in the coming decades.

Welding flaws

- Lamellar tearing is commonly observed discontinuity in fusion welding that occurs near the heat-affected zone in flange plates of T-butt joints. It is caused by factors like dilution and heat input during welding.

- Dilution is affected by the melted parent metal, melted filler metal, and weld width to depth ratio. Too low or too high heat input can both be detrimental.

- Solidification cracks can form due to the bead factor, which is the ratio of weld width to depth. A ratio greater than 1 or less than 1 can both result in cracks.

Aws d1.1 guides

This document provides guidelines for essential variables that determine the qualification range of a welding procedure specification in accordance with AWS D1.1 Structural Welding Code - Steel. It summarizes the qualification ranges for position, thickness/diameter, base metal selection, preheat requirements, joint details, heat input, and welding processes. The guidelines specify the testing parameters and qualified ranges for groove welds, fillet welds, plate and pipe configurations.

ASME SEC IX PPT.pdf

The document summarizes the key aspects of ASME Section IX (Ed. 2019), which contains requirements for welding procedure and performance qualifications. It discusses the history and timeline of ASME standards development. It also provides an overview of the various articles within ASME Section IX, including Article I on general welding requirements, Article II on welding procedure qualification, Article III on welding performance qualification, and Article IV on welding data. Key terms like essential variables, P-numbers, F-numbers, and A-numbers used for material grouping are also defined in the document.

Asme sec ix overview

This document provides an introduction to ASME Section IX, which establishes general guidelines for welding procedure and welder performance qualifications. It discusses the requirements for qualifying welding procedures using procedure qualification records (PQRs) and welding procedure specifications (WPSs). The key points covered include:

- ASME Section IX covers the qualification of welding and brazing procedures.

- Welding procedure qualifications demonstrate that a set of welding variables can reliably produce sound welds.

- WPSs and PQRs are used to document and qualify welding procedures. A WPS must be supported by a qualified PQR to be used for production.

It also summarizes the classification of base metals using 'P' numbers,

Wis5 welding defects 02

The document discusses various welding defects that can be visually detected, including cracks, lack of solid metal, lack of fusion, lack of smoothly blended surfaces, and miscellaneous defects. It provides details on different types of each defect, their causes, and methods for prevention. It also discusses welding repairs, noting that repairs require authorization and testing to ensure defects have been fully removed before performing the repair weld.

How to Qualify a Welding Procedure

The document outlines the five step process to qualify a welding procedure according to ASME Section IX. It provides details on developing a draft procedure using 0.75" A36 steel plate welded in the flat position using GTAW and GMAW. Variables such as joint design, base metal and thickness, filler metal type and size, welding position, and electrical parameters are documented. The qualification weld was tested to verify it results in an acceptable weld with proper mechanical properties before the welding procedure specification can be used in construction.

Welding of Similar & dissimilar - Metal filler chart

Welding technology

This chart shows Specification of filler wire while welding Similar & Dissimilar metals

How to produce PQR

This document outlines the 8 steps to produce a Procedure Qualification Record (PQR) according to the ASME Section IX code. The steps are: 1) identify essential variables for the welding process, 2) add remaining essential variables from construction codes, 3) fill out the PQR format, 4) choose a qualified welder, 5) record welding parameters, 6) perform visual and mechanical tests, 7) record test results on the PQR, and 8) sign and date the completed PQR.

What's hot (20)

Geit 10017 en-weldinspection rt interpretation-22-25

Geit 10017 en-weldinspection rt interpretation-22-25

pdfslide.net_120174253-twi-radiographic-interpretation-weld-defects-repair.pdf

pdfslide.net_120174253-twi-radiographic-interpretation-weld-defects-repair.pdf

ASNT Radiographic Film Interpretation (RTFI) Notes-Dr. Samir Saad

ASNT Radiographic Film Interpretation (RTFI) Notes-Dr. Samir Saad

Welding of Similar & dissimilar - Metal filler chart

Welding of Similar & dissimilar - Metal filler chart

Viewers also liked

Rt Acceptance

The document provides acceptance criteria for various types of defects found during radiographic testing of welds based on different codes and standards including API 1104, SP-1174, B31.3, and ASME Section IX. It lists the maximum allowable size, length, and aggregate length of defects such as cracks, incomplete penetration, incomplete fusion, burn through, slag inclusions, porosity, and undercutting.

Radiographic interpretation

This document provides an overview of radiographic interpretation for periapical and panoramic dental x-rays. It defines dental radiography and describes the main intraoral and extraoral views. Periapical radiographs show the entire tooth and surrounding structures, and are useful for detecting dental issues like caries, periapical pathology, implants and more. Panoramic radiographs provide a wide view of the jaws and are used to assess issues like gross caries, fractures, cysts and tumors. The document outlines the normal radiographic anatomy seen in these views and provides guidance on interpreting radiographs through steps like localization, observation, interpretation and correlation to arrive at a diagnosis.

Api 1104 study guide

The passage discusses the importance of summarization for processing large amounts of text data. It notes that automatic summarization systems aim to condense long documents into shorter summaries while maintaining the most important concepts and entities. The challenges of building such systems include identifying the most salient pieces of information, understanding natural language at a deeper level, and generating coherent summaries.

Radiography ndt

Radiographic techniques are used to inspect castings and welds for defects. Common casting defects appear on radiographs as gas porosity, sand inclusions, shrinkage cavities, core shifts, metallic inclusions, cracks, and cold shuts. Weld defects include lack of penetration, incomplete fusion, slag inclusions, porosity, and undercut. Proper film processing, viewing conditions, and knowledge of defect appearances are required to accurately interpret radiographs and evaluate component quality.

Welding Inspection Cswip

The document discusses key terminology and concepts related to welding inspection. Some key points:

- It defines different types of welds (e.g. butt weld, fillet weld), joints (e.g. butt, tee, lap), and weld zones (e.g. weld metal, heat affected zone).

- It discusses joint preparation details like bevel angles, root faces, gaps for different joint types (e.g. single V, single J).

- It covers features of fillet welds like leg length, throat thickness, and how they relate. Leg length and throat thickness determine weld strength.

- It also discusses duties of a welding inspector like observing welding, recording

Welding defects

This document discusses welding defects and welding processes. It describes various types of welding including arc welding, gas welding, resistance welding, thermit welding, solid state welding, and newer welding techniques. It then discusses common welding defects such as slag inclusion, undercut, porosity, incomplete fusion, overlap, underfill, spatter, excessive convexity/concavity, excessive weld reinforcement, incomplete penetration, and excessive penetration. For each defect it provides the potential causes and recommendations for prevention and repair.

Radiographic interpretation

The document discusses radiographic interpretation in dentistry. It covers topics such as the components and role of radiographs, their use in diagnosis, and the steps involved in radiographic interpretation. Interpretation involves a three step process of visualization, perception, and integrating information. Key aspects of analyzing radiographs include examining the quality, viewing conditions, anatomical accuracy, and using a systematic approach to analyze normal anatomy, bone patterns, individual teeth, and associated structures.

ASTM-E446-standard reference radiographs for steel castings up to 2 in. (50.8...

ASTM-E446-standard reference radiographs for steel castings up to 2 in. (50.8...Gulfnde Industrial Services

This document provides standards for reference radiographs used to evaluate steel castings up to 2 inches thick. It includes:

1. An overview of the scope and purpose of the reference radiographs, which illustrate various types and severity levels of discontinuities commonly found in steel castings.

2. Descriptions of the categories and types of discontinuities represented, including gas porosity, inclusions, shrinkage, cracks, tears, and mottling. The discontinuities are graded on a scale of 1 to 5 based on their quantity, size, and distribution.

3. Procedures for how to use the reference radiographs to evaluate production radiographs and determine whether castings meet specified radiPipeline Welding

This document discusses requirements for quality pipe welding. It begins by noting that pipelines are now inspected more rigorously, using improved techniques, and to higher standards approaching zero defects. This poses challenges for welders used to more lenient standards. The document recommends improving joint preparation, thoroughly cleaning surfaces, and showing welders radiographs to help them understand and correct errors. Maintaining proper joint geometry and root spacing is important to avoid issues like internal undercut.

Radiography Testing Presentation

Detailed Presentation on Radiography Testing. It is prepared on the lines of ASNT Level II pattern.

A V Abhishek

abhishek.agyarapu@gmail.com

Welding Defects

The document discusses common welding defects identified by Engr Muhammad Hussain, an inspection engineer at Global NDE Services Pvt. Ltd in Karachi. It lists undercut, porosity, incomplete fusion, overlap, underfill, spatter, excessive convexity, excessive concavity, excessive weld reinforcement, incomplete penetration, excessive penetration, and unacceptable weld profiles as defects addressed by Engr Hussain in his role.

Acceptance Criteria

The document discusses the user story lifecycle including conducting an inception, identifying roles and personas, eliciting business processes, generating user stories, arranging stories into releases and iterations, and providing details for developers using techniques like happy path, sad path, being SMART, and Given, When, Then. It emphasizes that developers need details to implement stories effectively.

Welding basics1

The document provides an overview of TIG (GTAW) welding. It involves using a tungsten electrode to generate an electric arc that melts the materials to be welded. The welding area is shielded with an inert gas like argon to prevent contamination. TIG welding allows for good control and produces high quality welds, making it suitable for thin metals. However, it is more complex and difficult to learn than other welding techniques. It requires maintaining a small arc gap and feeding a filler rod with one hand while operating the torch with the other.

9488085 welding-defects

The document discusses various types of discontinuities and defects that can occur in welding, including cracks, porosity, inclusions, insufficient penetration, and more. It defines discontinuities as interruptions in material structure that are not necessarily defects, while defects render a part unable to meet standards. Causes, preventions, and potential repairs are provided for each issue. Engineering problems can arise from design mistakes, while weld process issues relate to techniques and metallurgy.

Welding ppt

Welding is a process that joins materials by heating them to melt or soften them and allowing them to cool, forming a permanent bond. It is commonly used to join metal parts in manufacturing. Some key types of welding include arc welding, gas welding, resistance welding, and solid state welding. Welding is used in many industries such as automotive, aerospace, shipbuilding, and construction.

Weld Defects and Material Properties - Presentation

This document discusses weld defects, specifically porosity in welds. It defines porosity as gas holes or voids found within a weld caused when gases trapped in the weld do not escape as it solidifies. The document outlines the main causes of porosity as dirt and moisture, describes the detrimental effects on strength and fatigue life, and provides methods for preventing and detecting porosity, including maintaining cleanliness and using non-destructive testing techniques.

Viewers also liked (17)

ASTM-E446-standard reference radiographs for steel castings up to 2 in. (50.8...

ASTM-E446-standard reference radiographs for steel castings up to 2 in. (50.8...

Weld Defects and Material Properties - Presentation

Weld Defects and Material Properties - Presentation

Radiographic interpretation

- 1. RADIOGRAPHS REFERENCE NO.1 EXCESSIVE ROOT PENETRATION ROOT CONCAVITY INCOMPLETE FILLED GROOVE CAP UNDERCUT ROOT UNDERCUT SPATTER LONGITUDINAL CRACK TRANSVERSE CRACK CRATER CRACK Excessive Root Penetration: a continuous or intermittent light irregular band within the image of the weld. Root Concavity: a series of dark areas along the centre of the weld varying in density according to the depth of imperfection. Incomplete Filled Groove: a dark area towards the centre of the weld which has diffuse edges. Undercut: a dark / irregular/ intermittent band in a position adjacent to either the cap or root weld toe or between adjacent capping runs. Spatter: small light/white spots. Crack: dark, fine often branching lines which are usually diffuse or discontinuous. Copyright2013:KAOriginal Prepared by Kamarul Ariffin, (PCFSSB)

- 2. RADIOGRAPHS REFERENCE NO.2 LACK OF ROOT FUSION INCOMPLETE ROOT PENETRATION LINEAR SLAG INCLUSION COPPER INCLUSION SILICA INCLUSION CLUSTER POROSITY Lack of Root Fusion: lack of fusion with the parent material will appear in the radiograph as a fine dark straight line which may be continuous or intermittent Incomplete Root Penetration: as a dark continuous or intermittent linear shadow, the edges of which will usually be straight Linear Slag Inclusion: a straight edge often indicate lack of fusion. Sometimes linear slag will appear on the radiograph as two parallel lines Tungsten inclusion: appear as bright - light images which tend to be angular. They are usually quite small - typically around 0.5 mm Copper Inclusion: light rounded images with extremely diffuse edges Silica Inclusion: irregular dark image normally for MIG welding process. Cluster Porosity: sharply defined dark circular spots, may be isolated, grouped or evenly distributed. Linear Misalignment + LACK OF ROOT FUSION: noticeable difference in density between the two pieces. The dark, straight line is caused by the failure of the weld metal to fuse with parent material. Prepared by Kamarul Ariffin, (PCFSSB) TUNGSTEN INCLUSION MISALIGNMENT + LACK OF ROOT FUSION LINEAR MISALIGNMENT Copyright2013:KAOriginal

- 3. RADIOGRAPHS REFERENCE NO.3 SLAG INCLUSION ROOT PASS ALIGNED POROSITY HERRINGBONE POROSITY DEBRIS WORMHOLE LACK OF SIDEWALL FUSION Burn Through: dark spots, which are often surrounded by light globular areas . Slag Inclusion: slag may appear in various shapes, from long narrow indications to short wide indications, and in various densities, from grey to very dark Root Aligned Porosity, Herringbone Porosity : a series of rounded gas pockets or voids in the weld metal, and is generally cylindrical or elliptical in shape. Arc Strike: dark, sometimes white indication from a localized heat-affected zone or a change in surface contour of a finished weld or adjacent base metal Debris: white image scattered normally by foreign material inside pipe Wormholes: a dark shadow the shape of which depends on the orientation of the defect. If the wormhole is end on to the radiation a very dark rounded shadow is formed. If the wormhole is side on then the appearance is somewhat like a tadpole Lack of Sidewall Fusion: lack of fusion with the parent material will appear in the radiograph as a fine dark straight line which may be continuous or intermittent Copyright2013:KAOriginal ARC STRIKEBURN THROUGH INTERPASS SLAG INCLUSION PreparedbyKamarulAriffin,(PCFSSB)