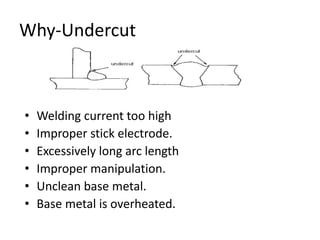

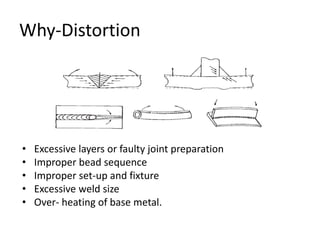

This document discusses common defects that can occur in submerged arc welding, including blowholes, undercut, slag inclusions, incomplete penetration, cracks, distortion, burn-up, arc blow, pits, and overlap. For each defect, it identifies potential causes and recommendations to avoid the defect, such as properly cleaning the base metal, using the correct welding current and travel speed, preheating materials, and ensuring a stable welding environment. The goal is to help welders identify and address issues that could compromise the quality and integrity of their welds.