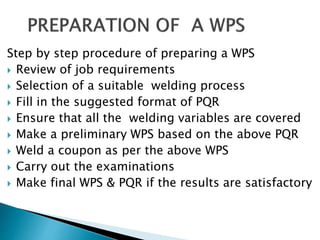

This document discusses the requirements for welding procedure specifications (WPS), procedure qualification records (PQR), and welder performance qualifications (WPQ) according to the ASME Boiler and Pressure Vessel Code. It explains that a WPS provides direction for production welds to meet code requirements, a PQR documents the variables and test results used to qualify a welding procedure, and WPQ tests determine a welder's ability to use a qualified WPS to produce sound welds. The document outlines the specific requirements and processes for developing, qualifying, and documenting each of these elements according to the ASME code.