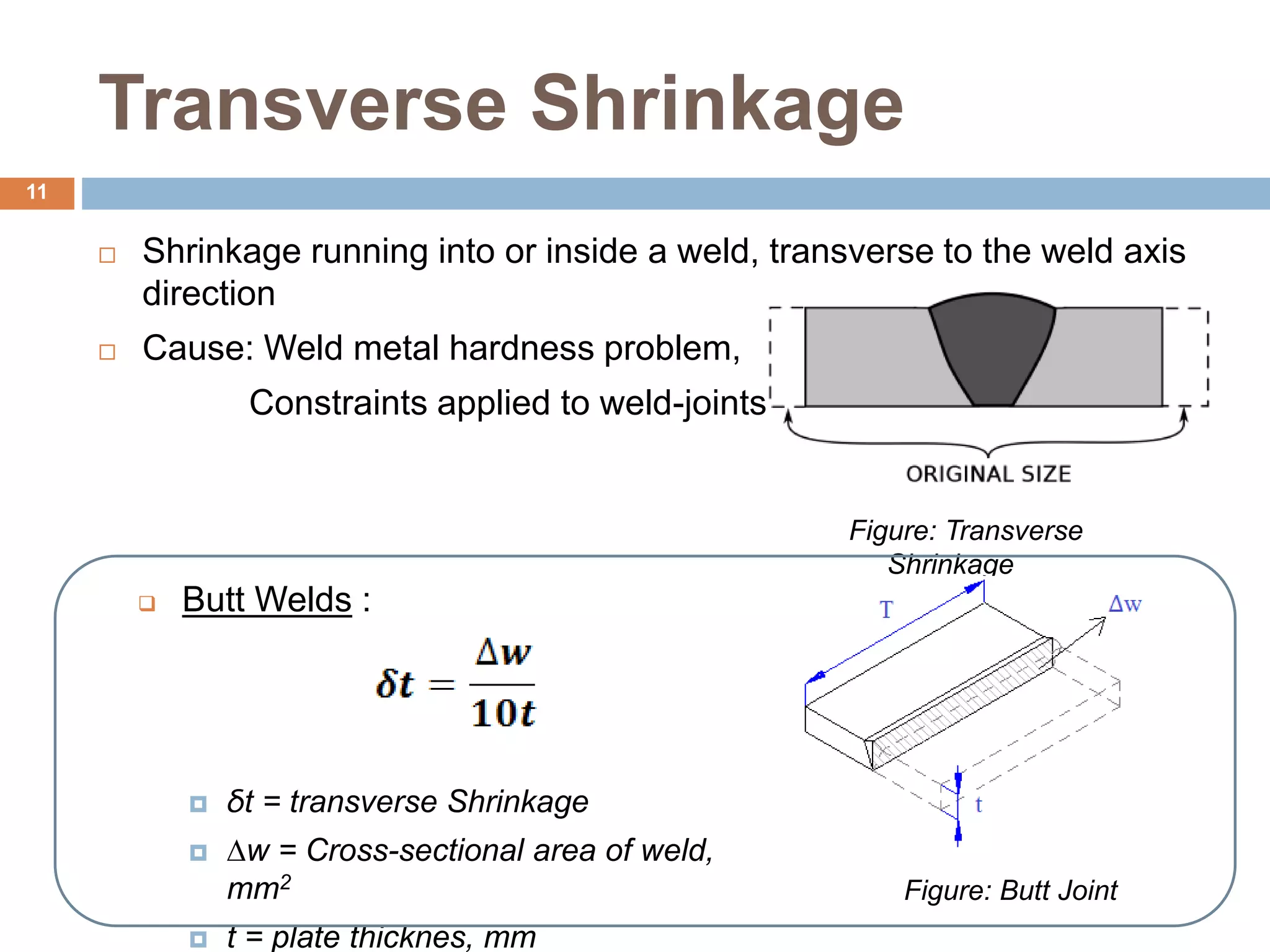

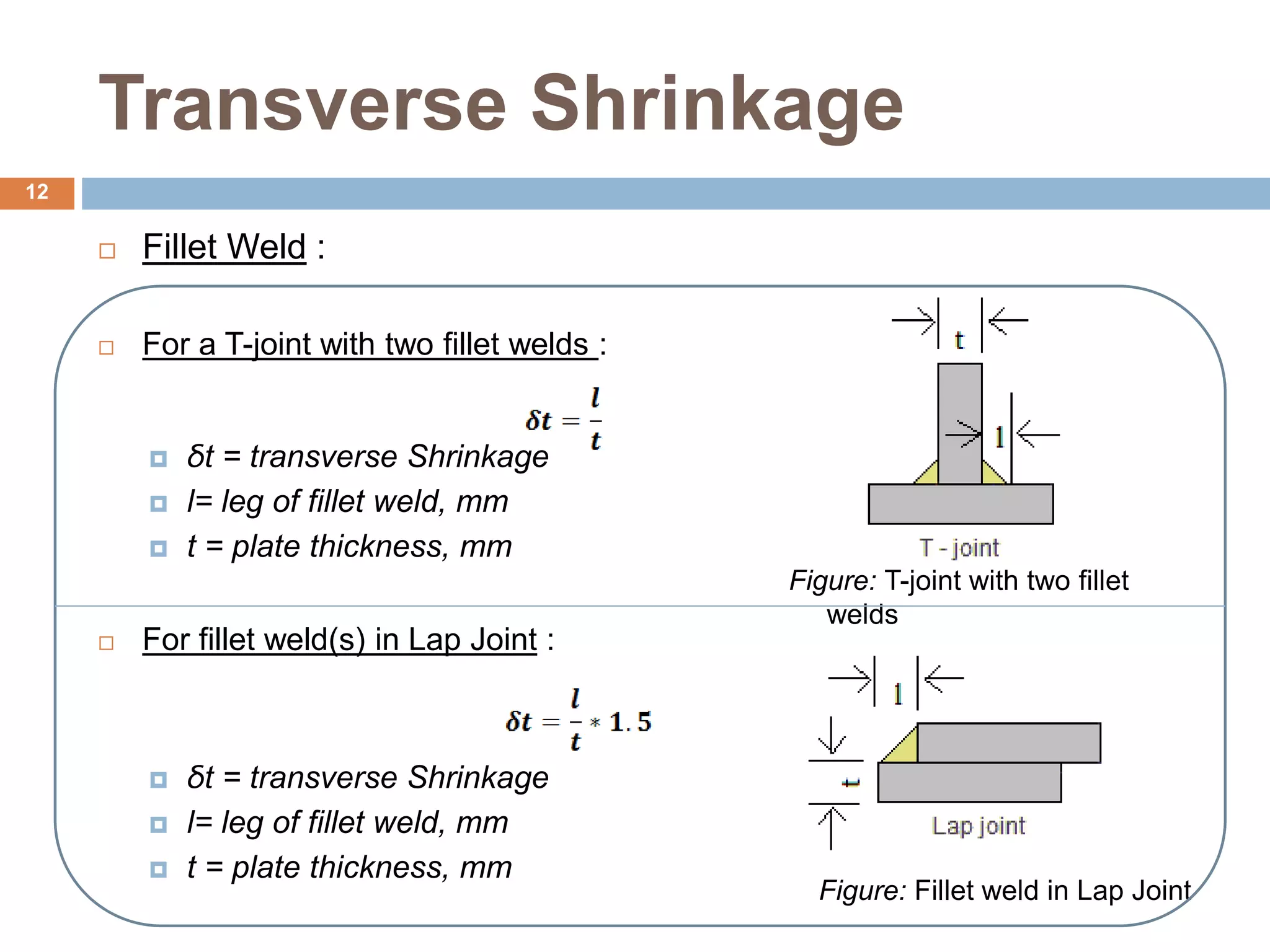

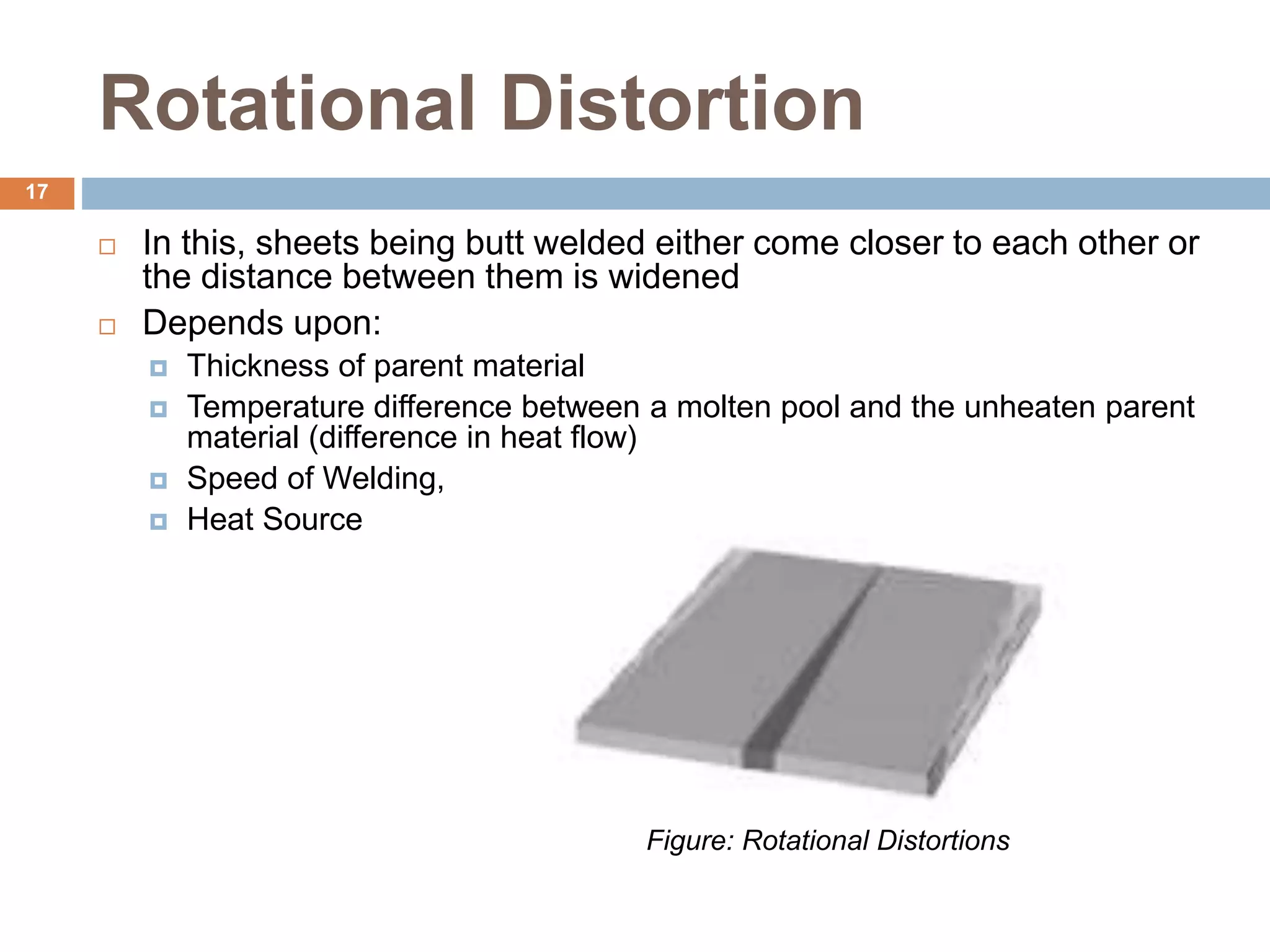

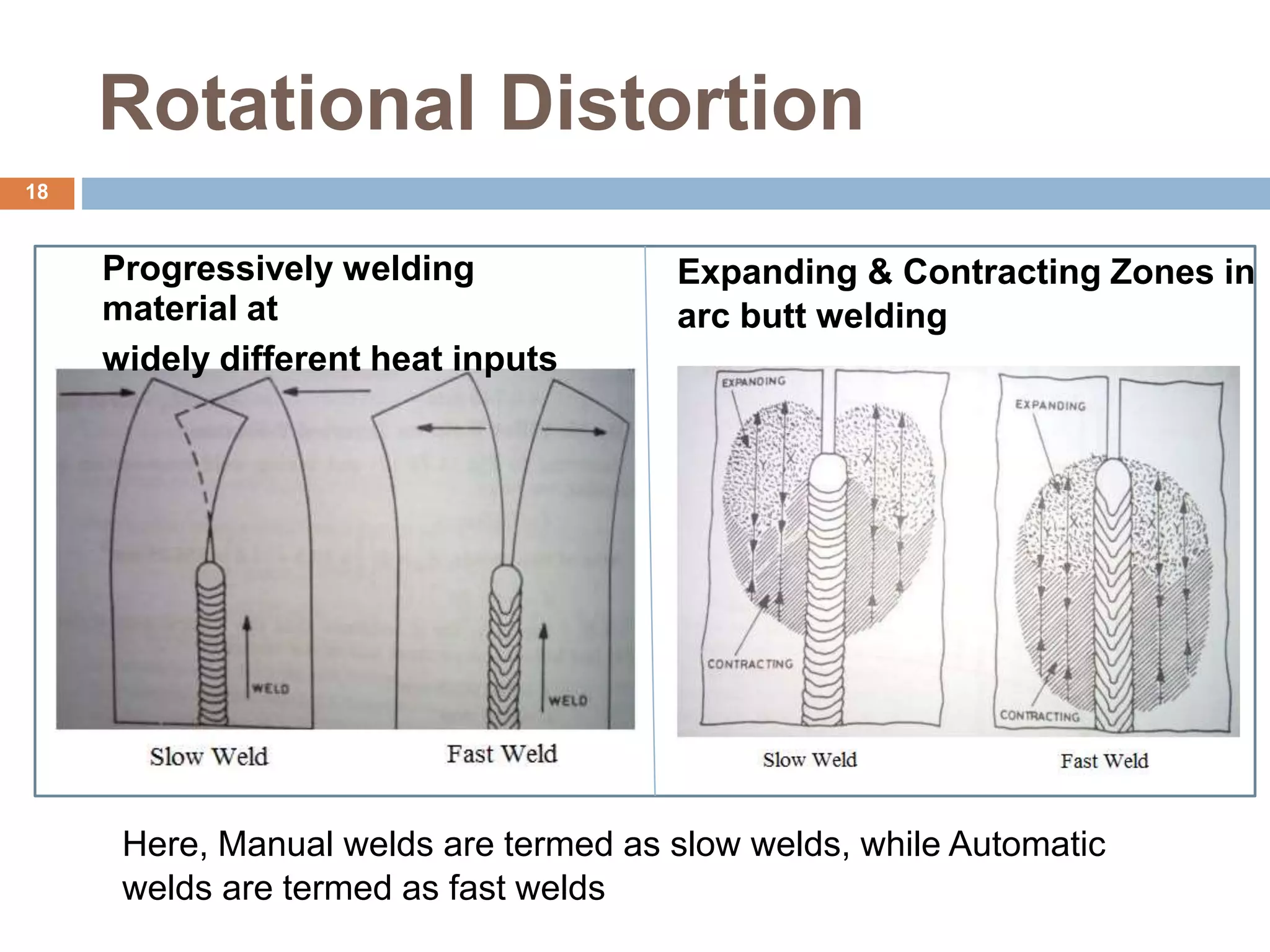

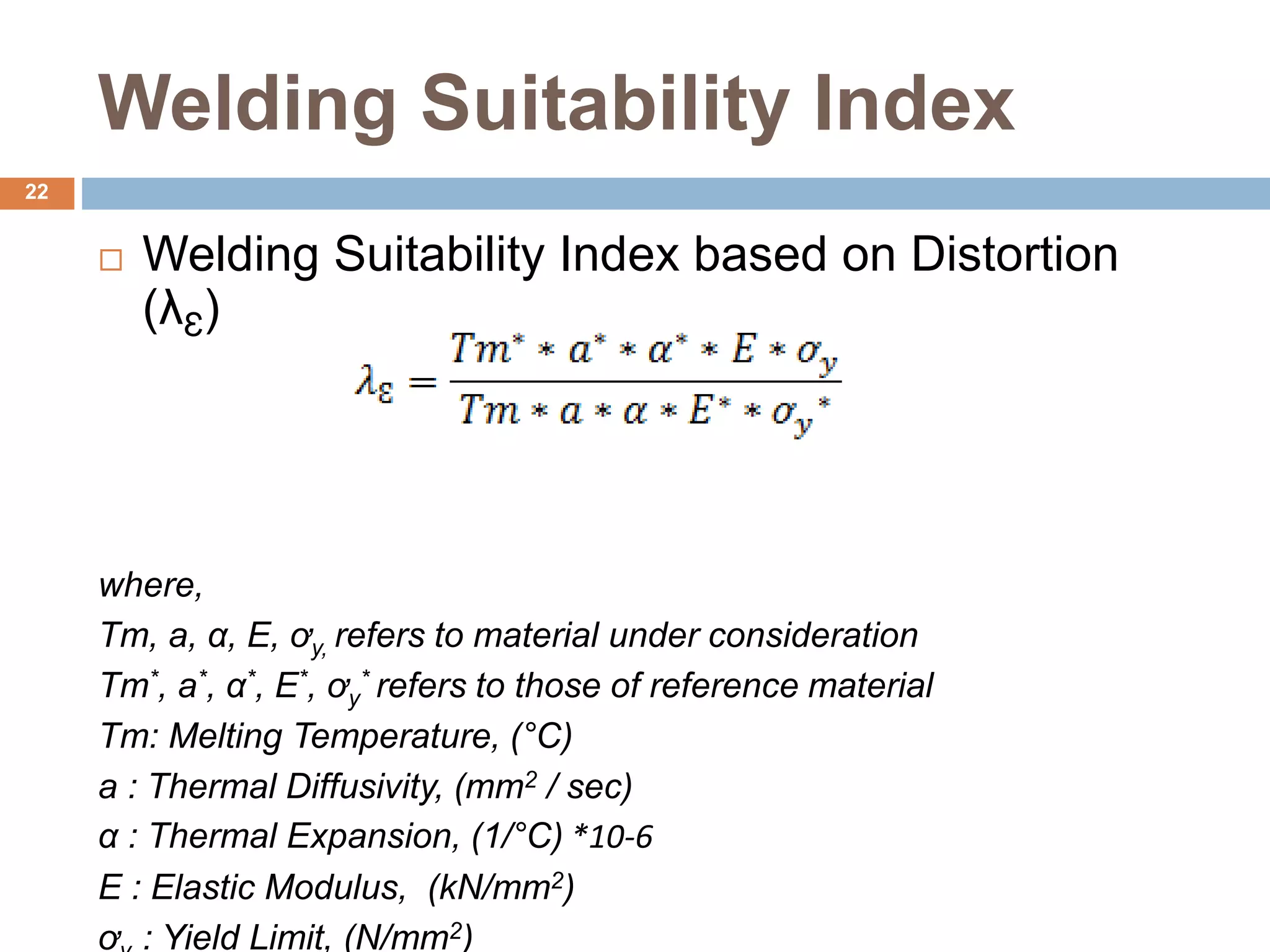

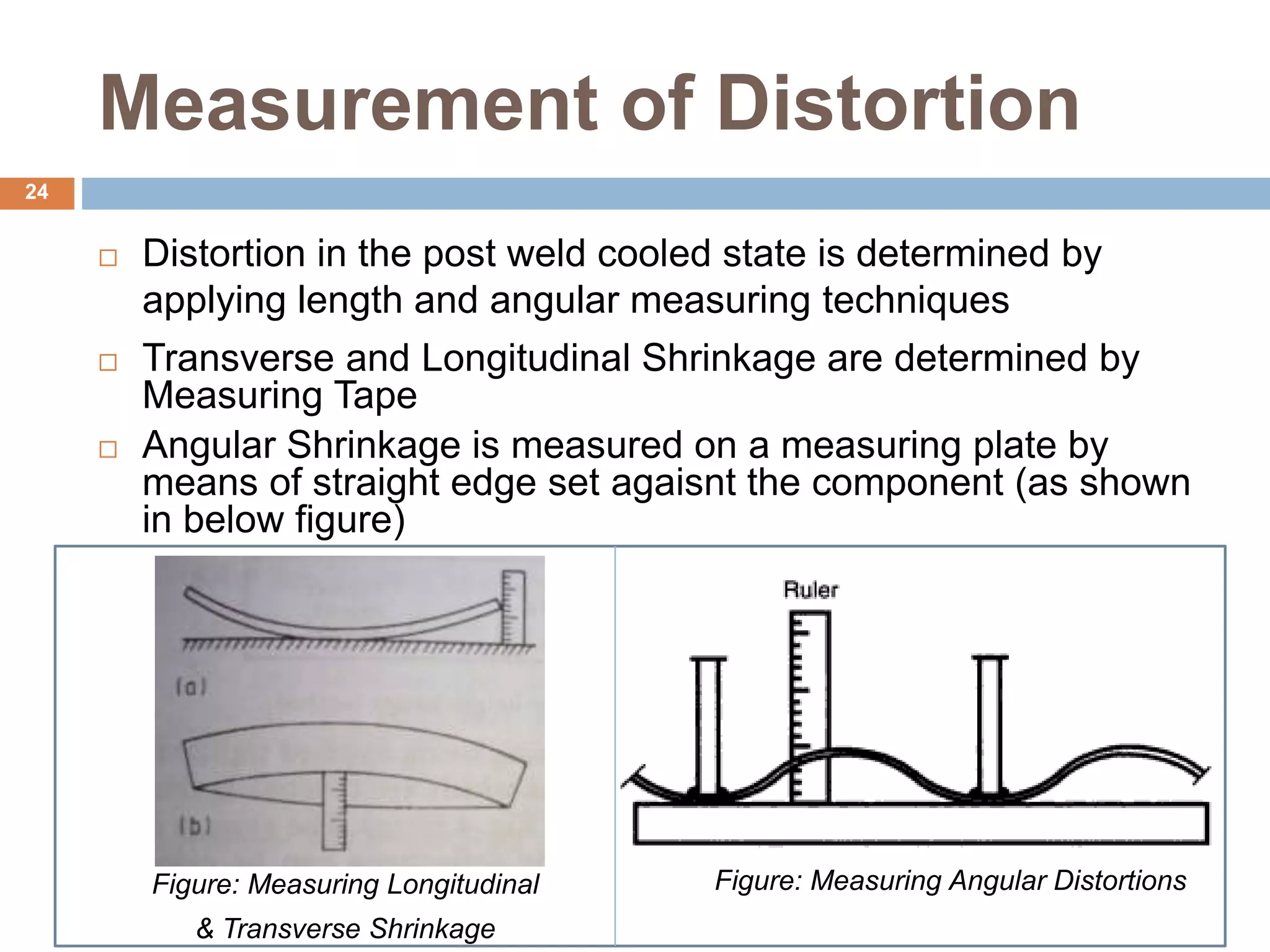

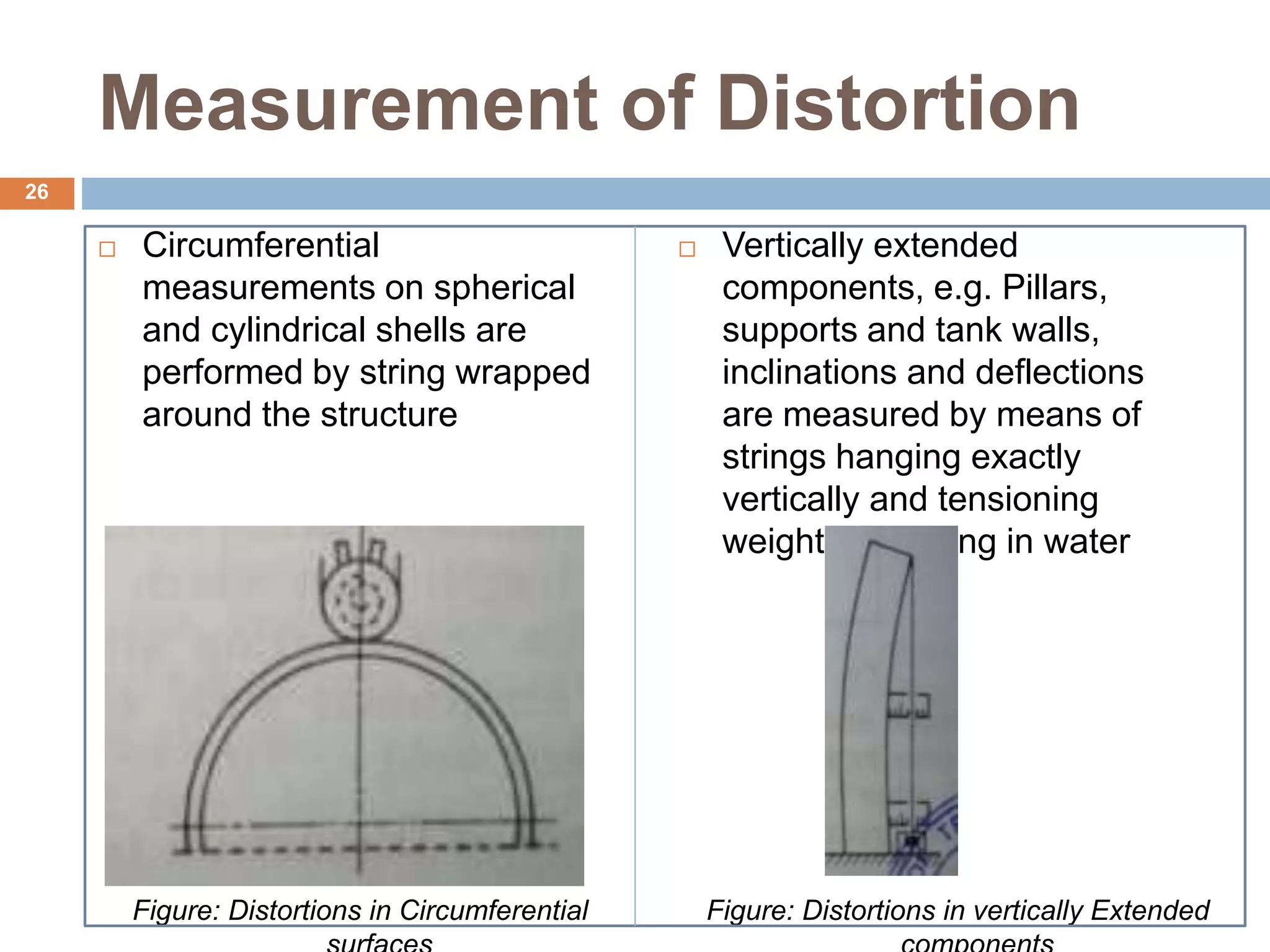

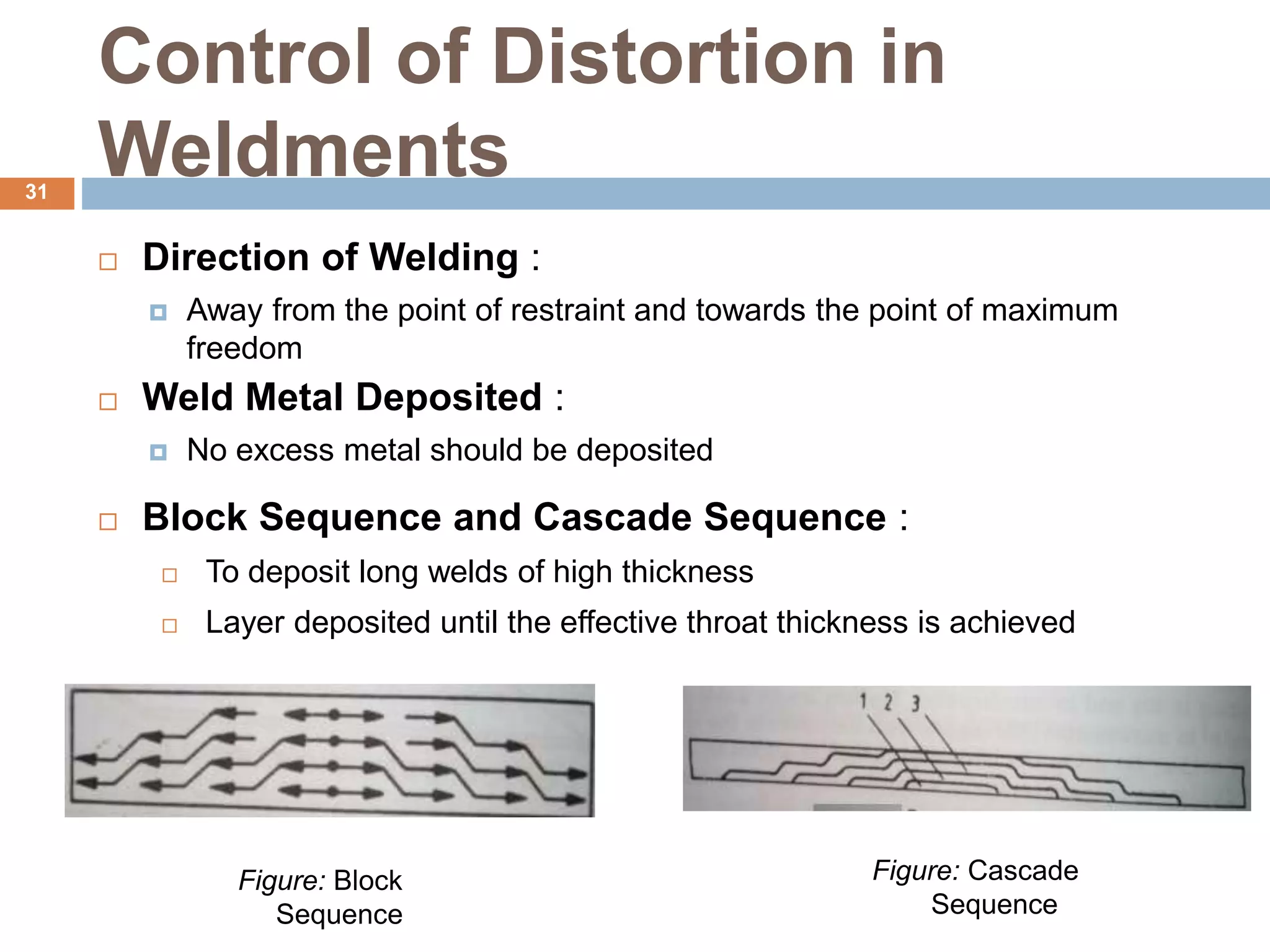

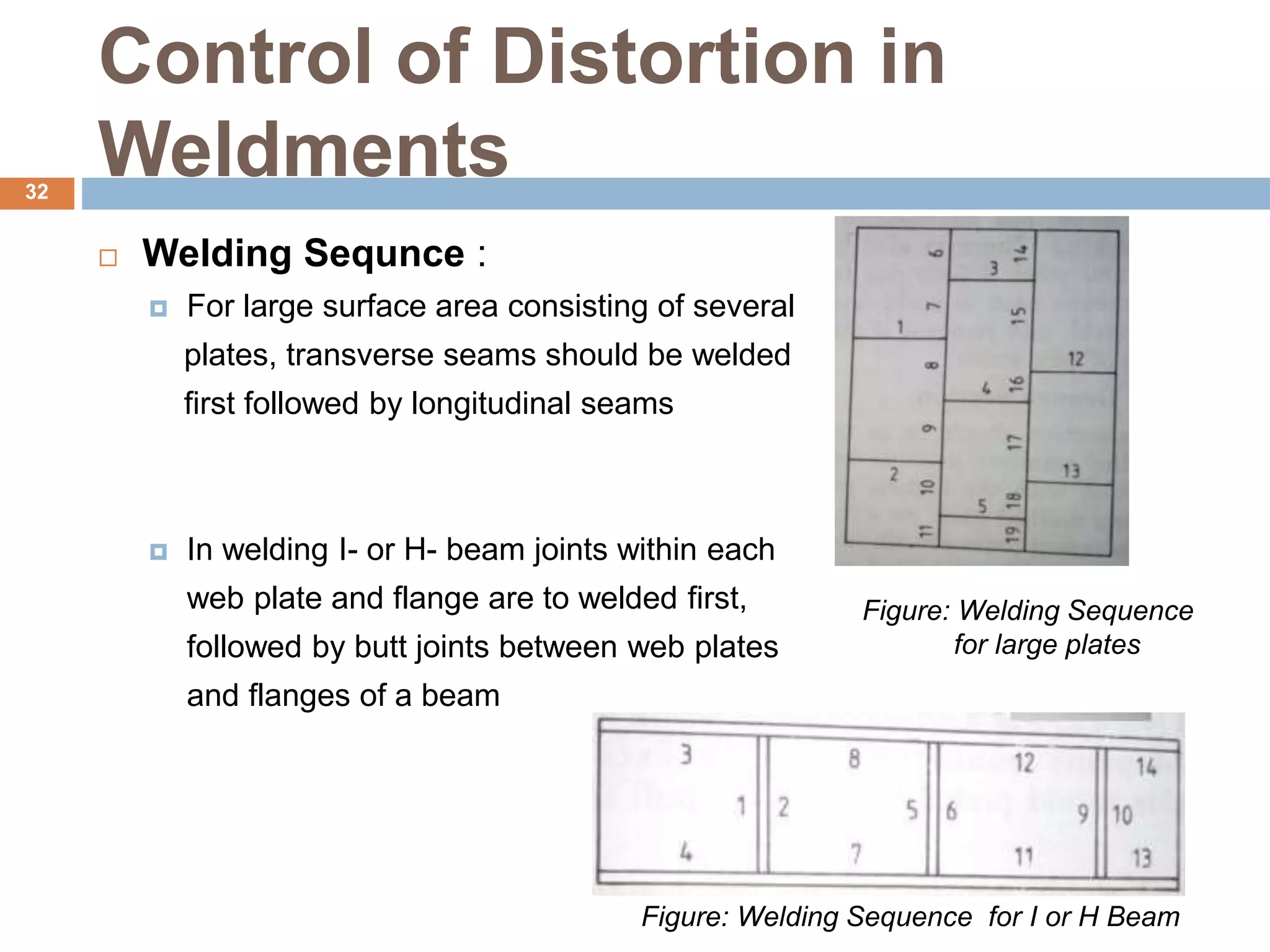

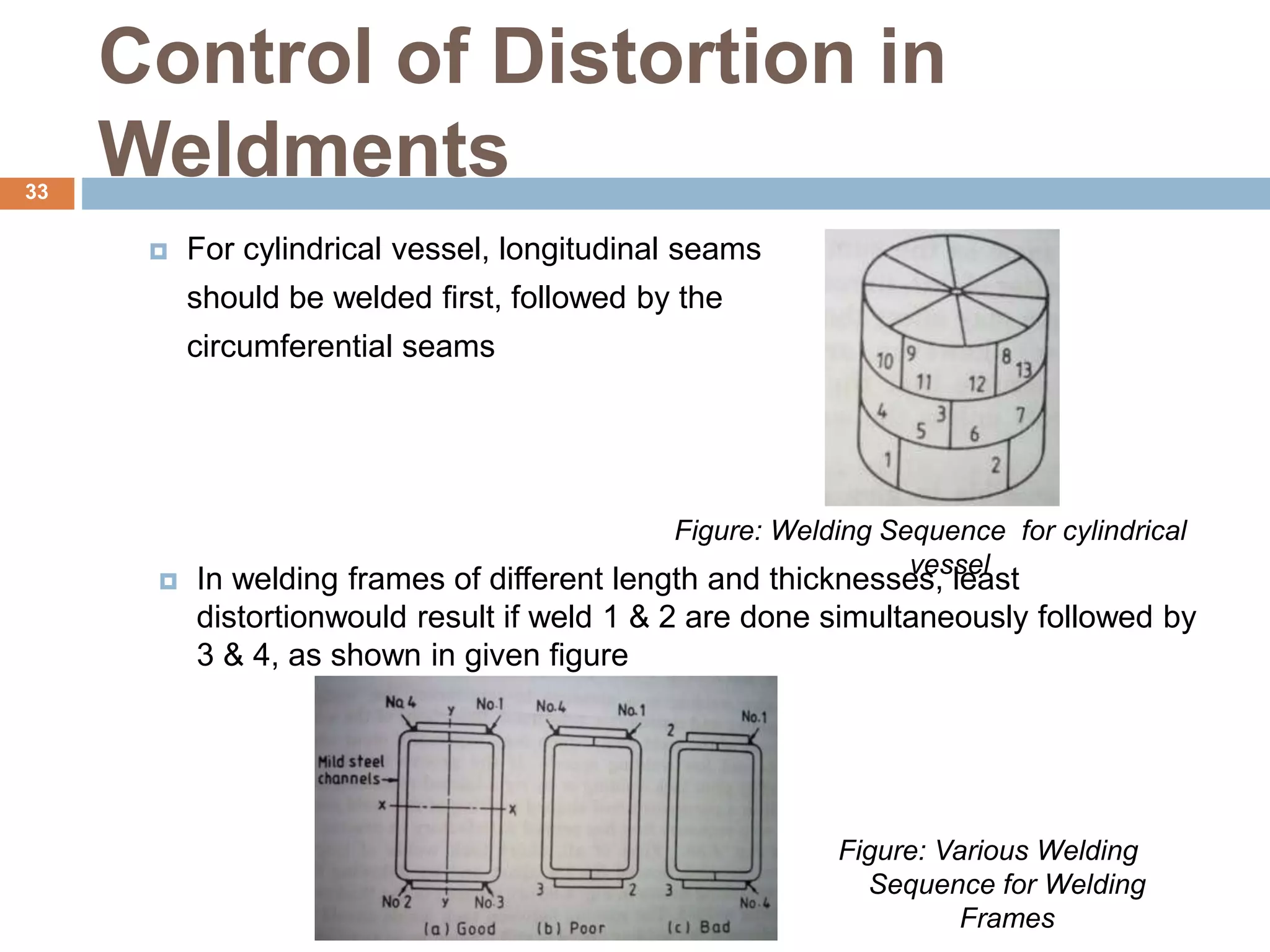

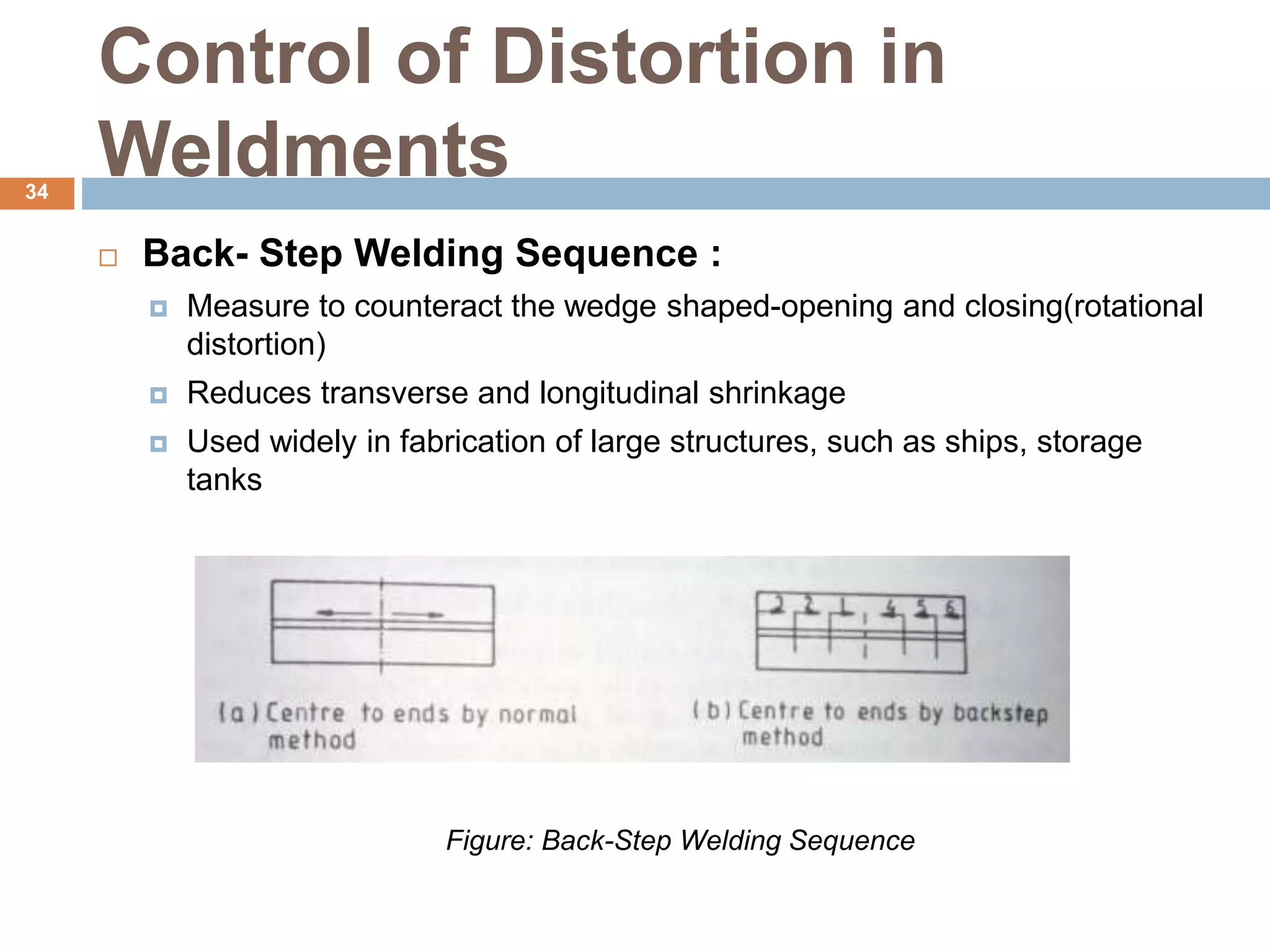

This document discusses distortion that can occur during welding processes. It defines distortion as any unwanted physical change to a fabricated structure due to welding. The main causes of distortion are non-uniform expansion/contraction from the welding thermal cycle and internal stresses formed in the base metal. The extent of distortion depends on material properties like thermal expansion and welding factors like process, amount of weld metal, and edge preparation. Different types of distortions like longitudinal, transverse, angular, bending, twisting and buckling are described. Methods to measure and control distortion include welding sequence, fixtures, preheating, and post weld heat treatment. Various materials have a welding suitability index calculated to indicate their distortion sensitivity during welding.