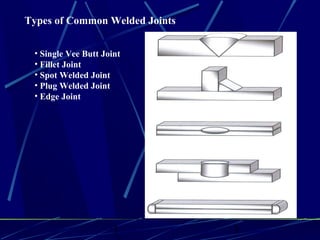

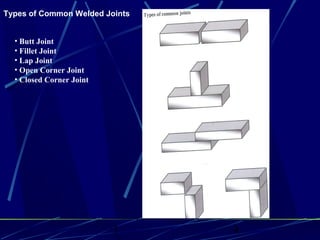

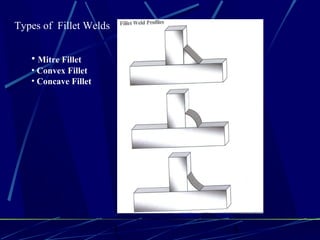

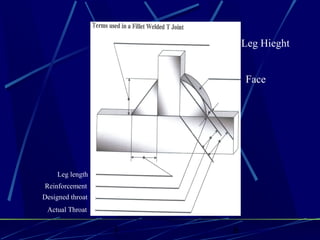

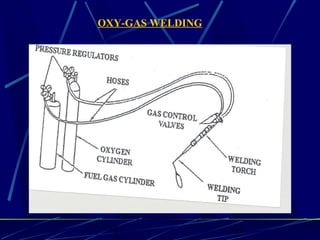

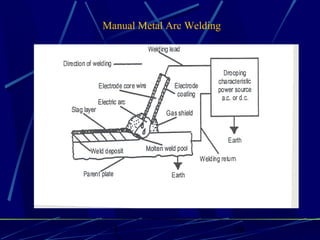

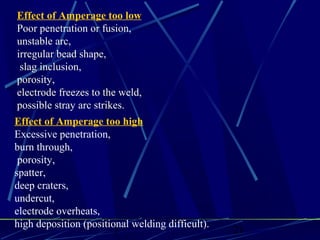

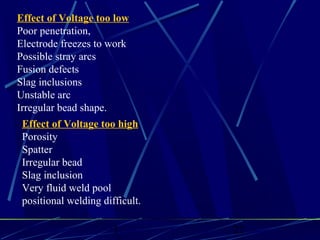

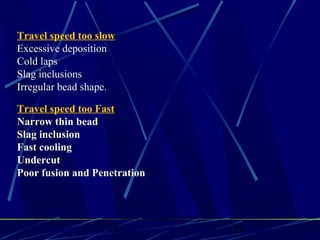

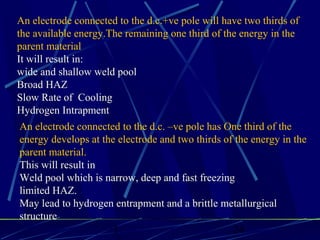

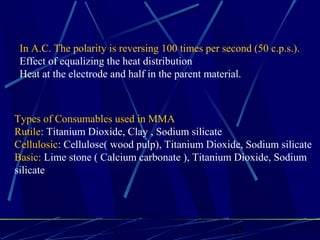

Welding is a process that joins materials by causing coalescence and can be accomplished with or without the use of filler material. There are several common welded joint types including butt, fillet, lap, and corner joints. Various welding processes are described including oxy-fuel welding, shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and gas tungsten arc welding (GTAW). Key factors that affect the quality of a weld include current, voltage, travel speed, and gas selection depending on the specific process.