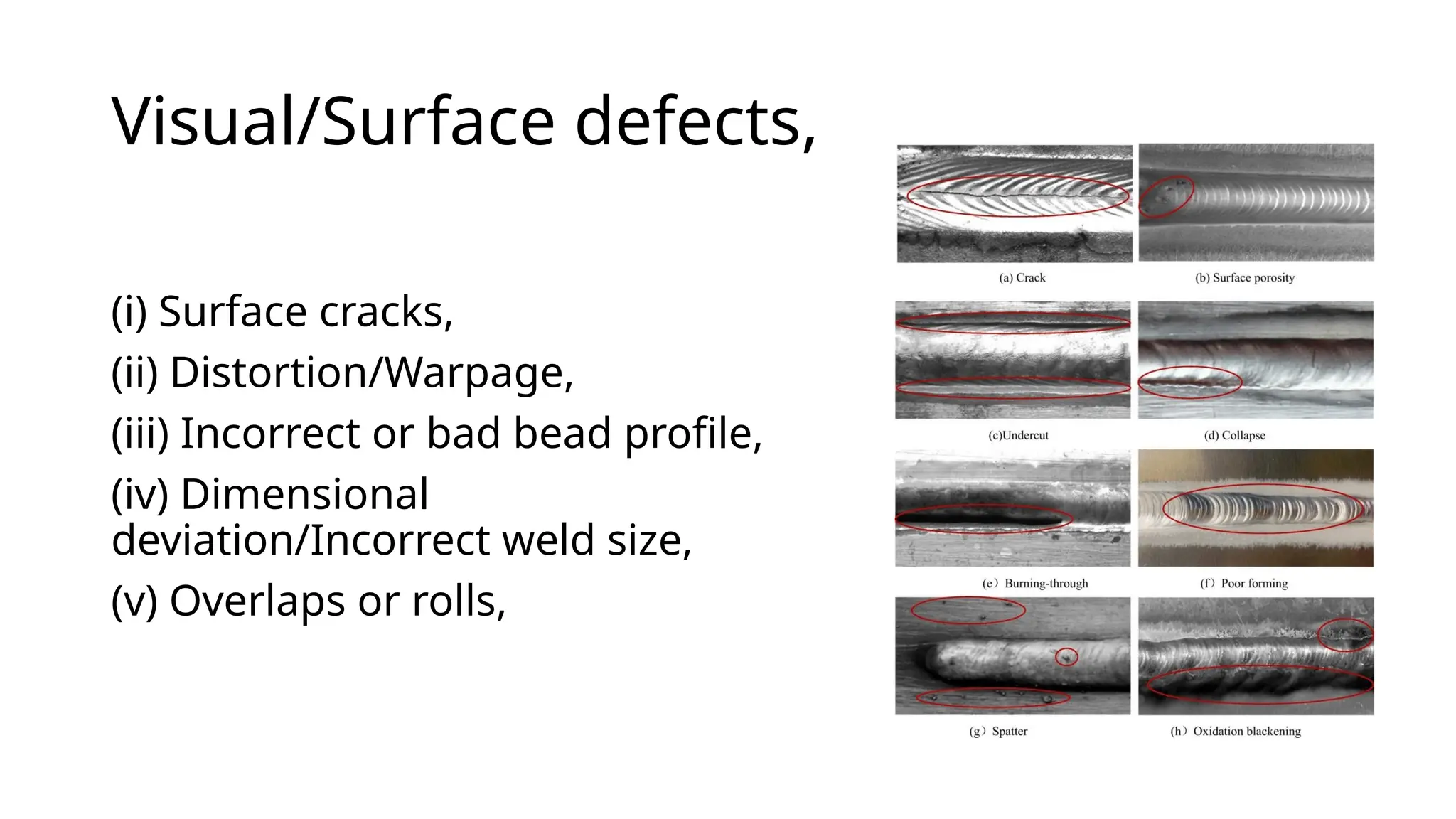

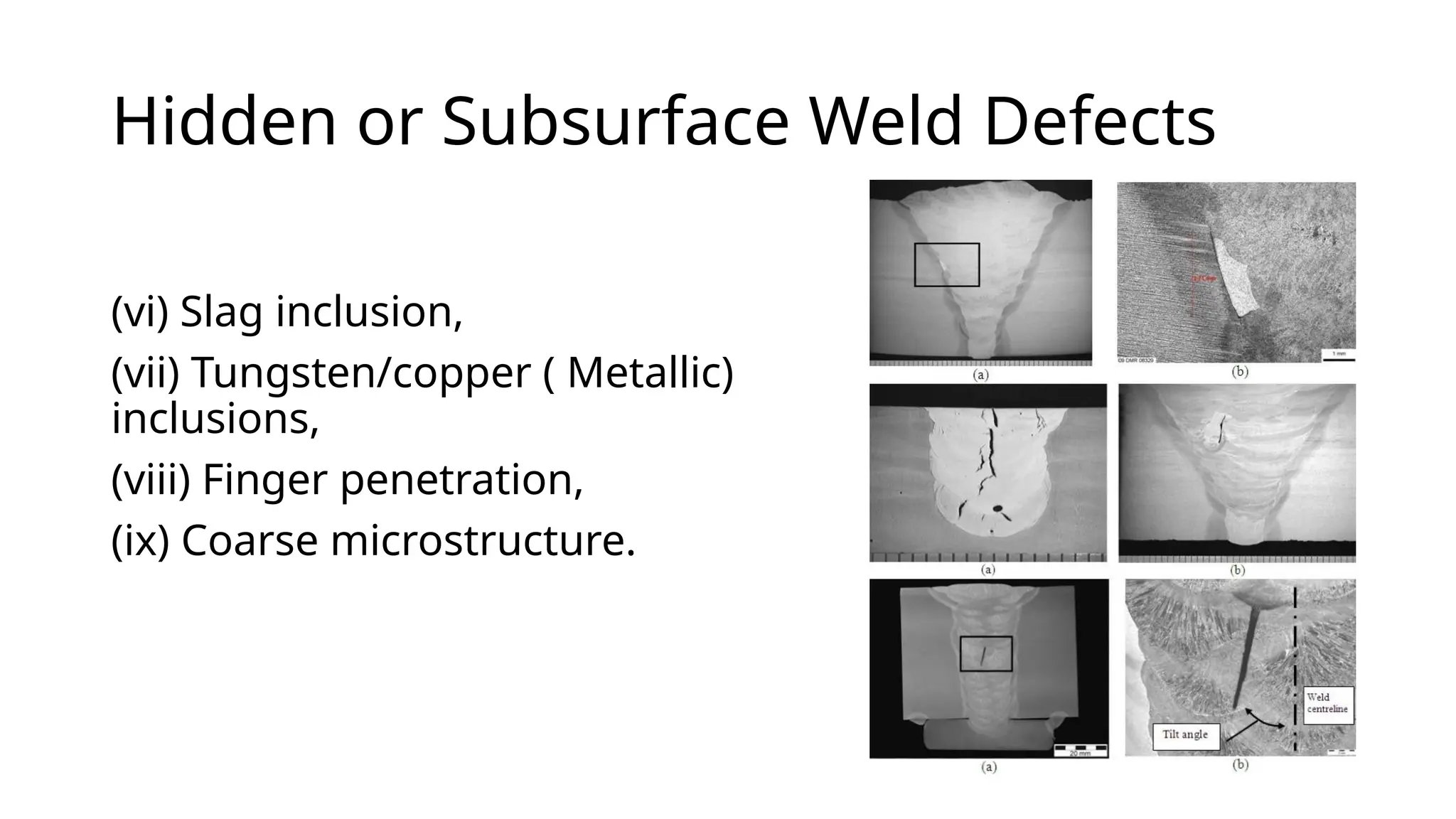

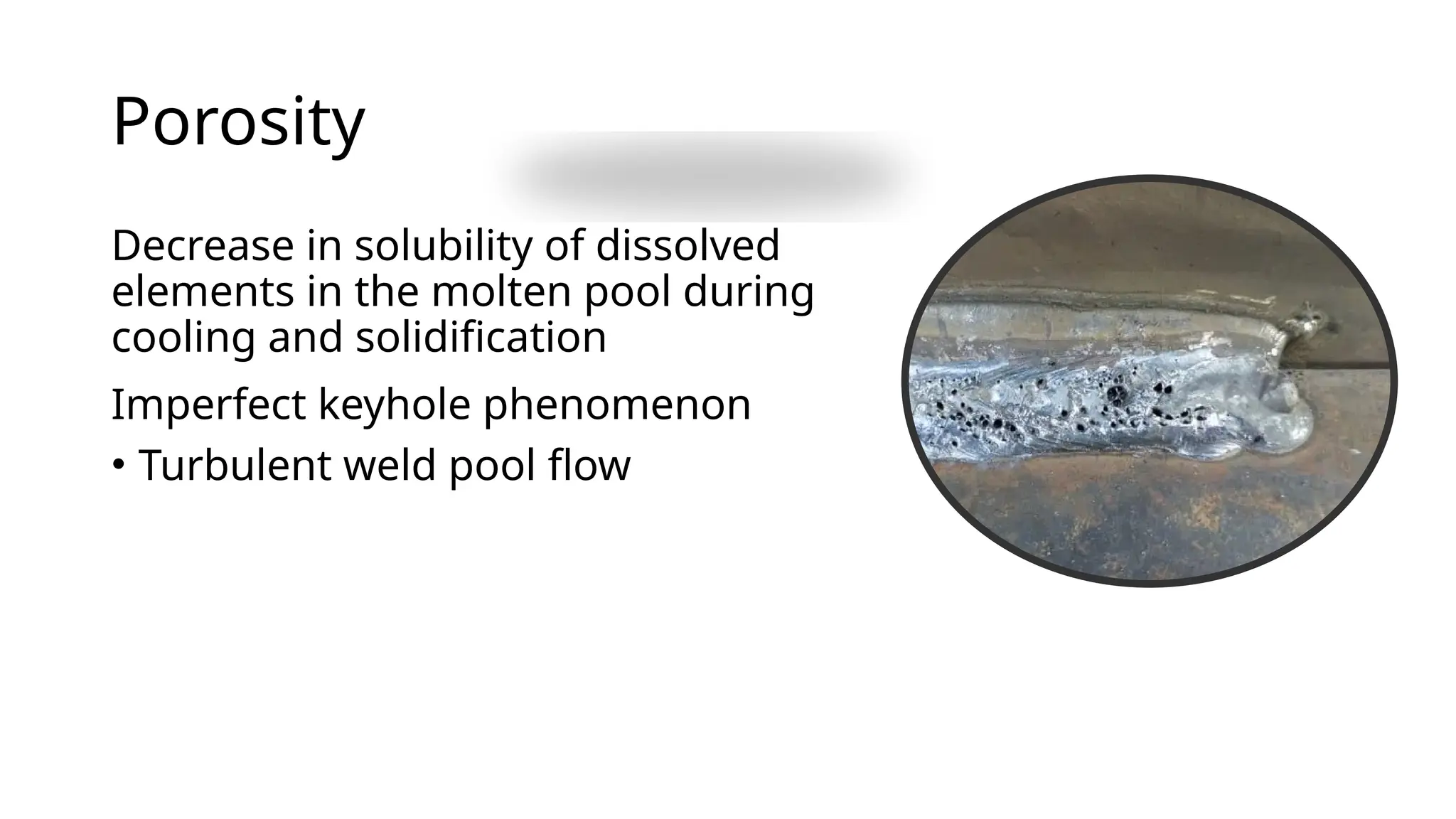

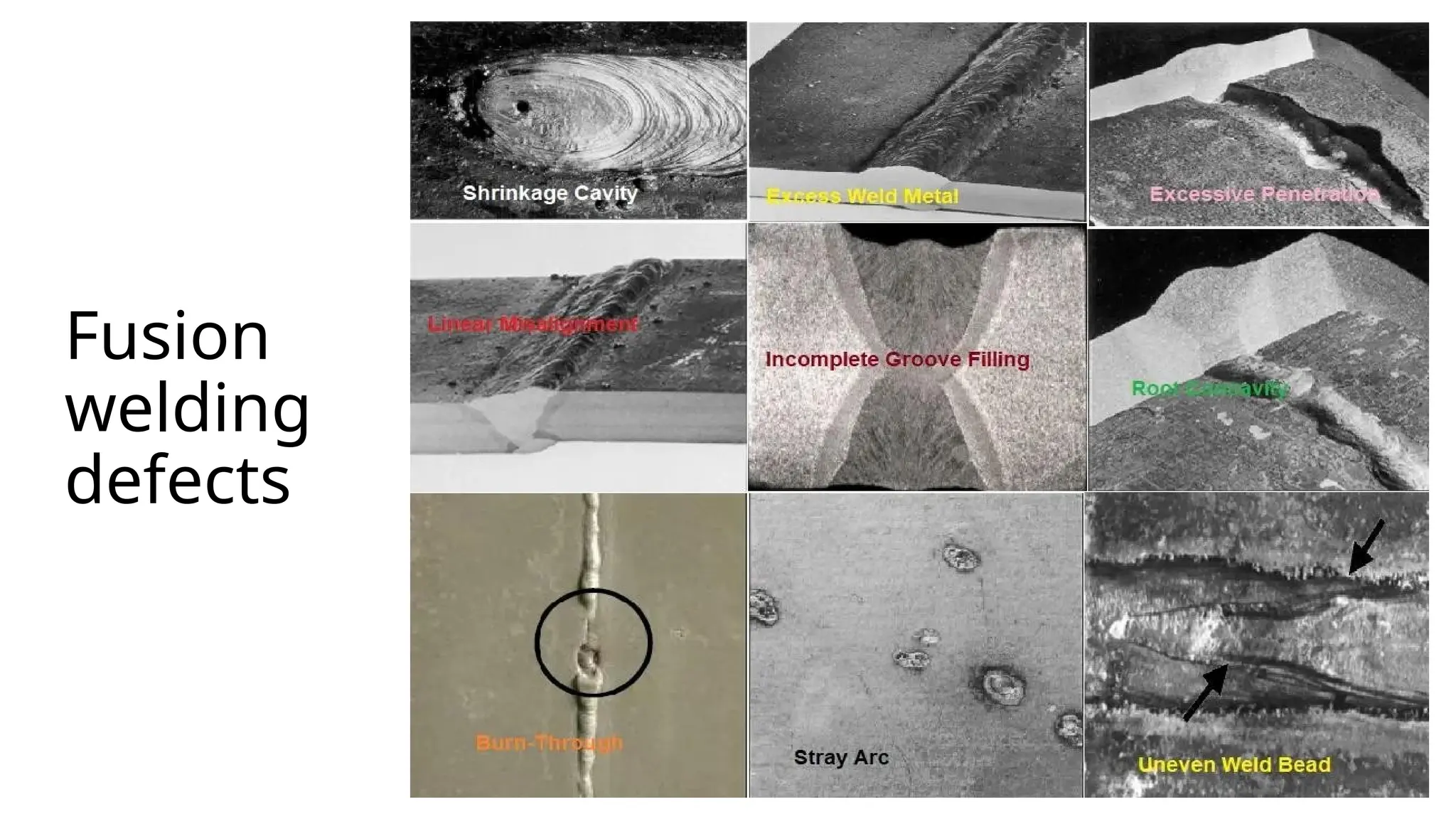

This document classifies various welding defects into surface and subsurface categories, detailing types such as surface cracks, porosity, and lack of fusion. It discusses the causes of these defects, including improper welding parameters, material interactions, and skill level of the welder. Additionally, it highlights the consequences of these defects on weld integrity and methods for correction and prevention.