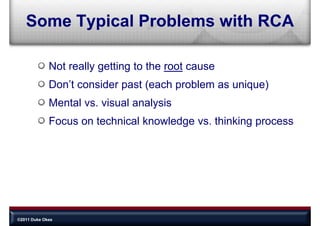

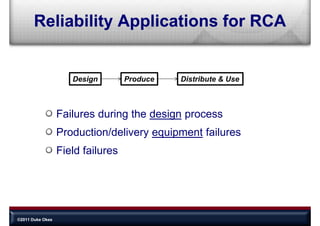

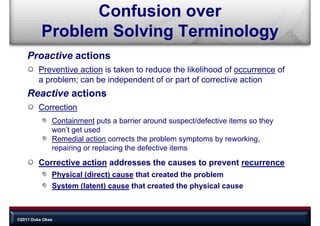

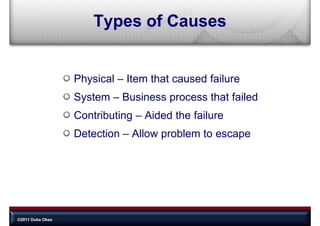

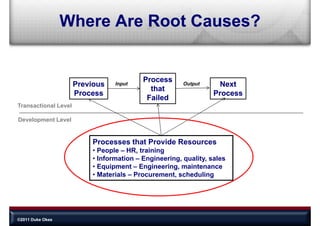

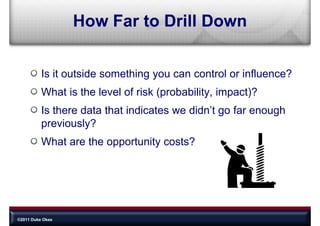

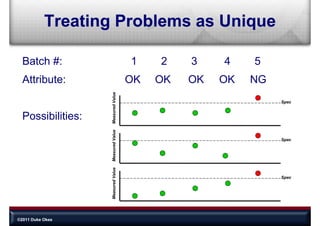

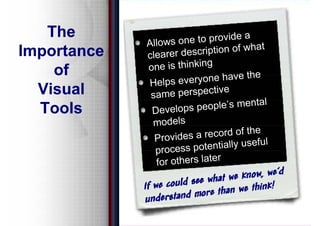

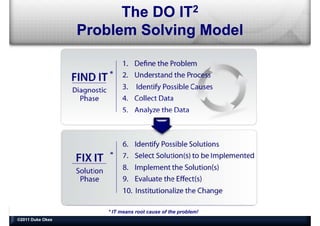

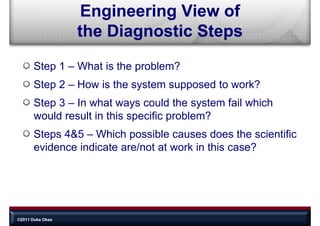

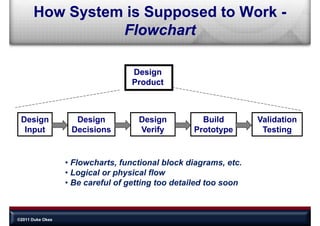

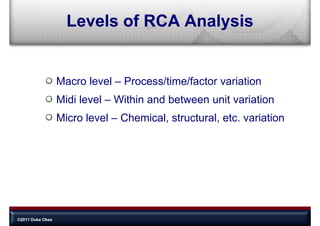

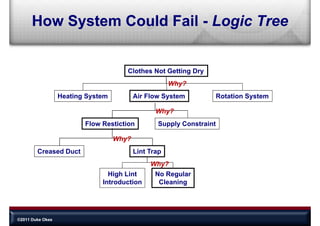

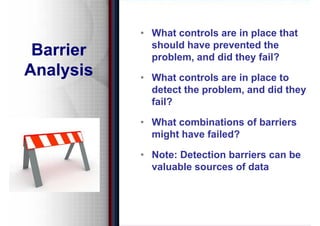

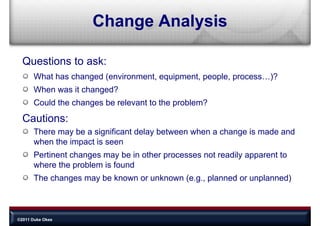

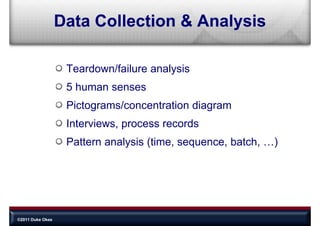

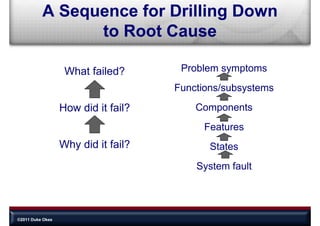

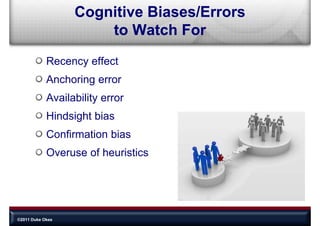

The document discusses root cause analysis (RCA), highlighting common problems and solutions faced by reliability engineers. It outlines the importance of identifying various causes, employing visual tools for analysis, and the systematic approach to diagnosing issues in processes. The ultimate goal is to build institutional knowledge to prevent recurrence of issues and improve processes based on insights gained from RCA.