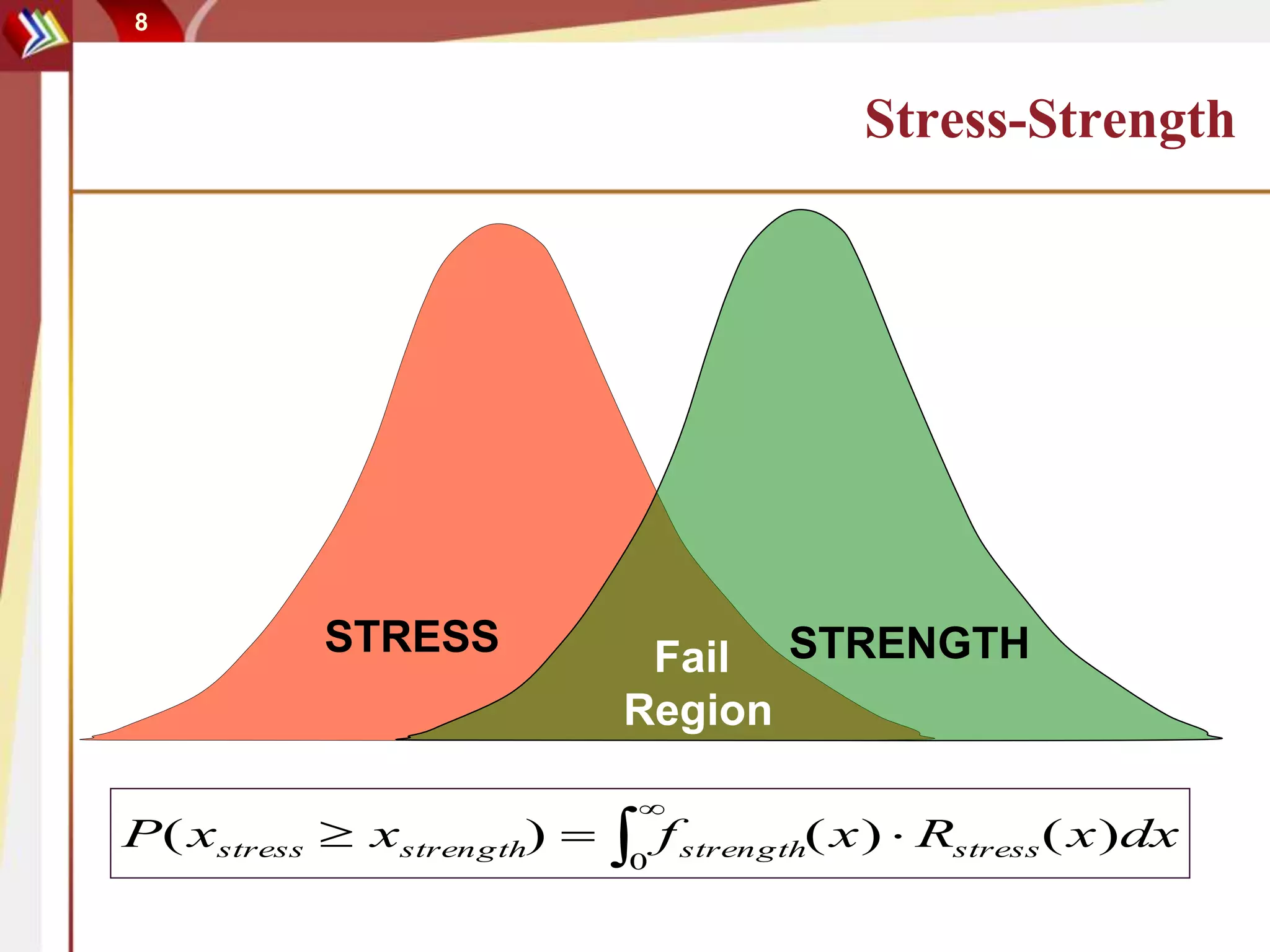

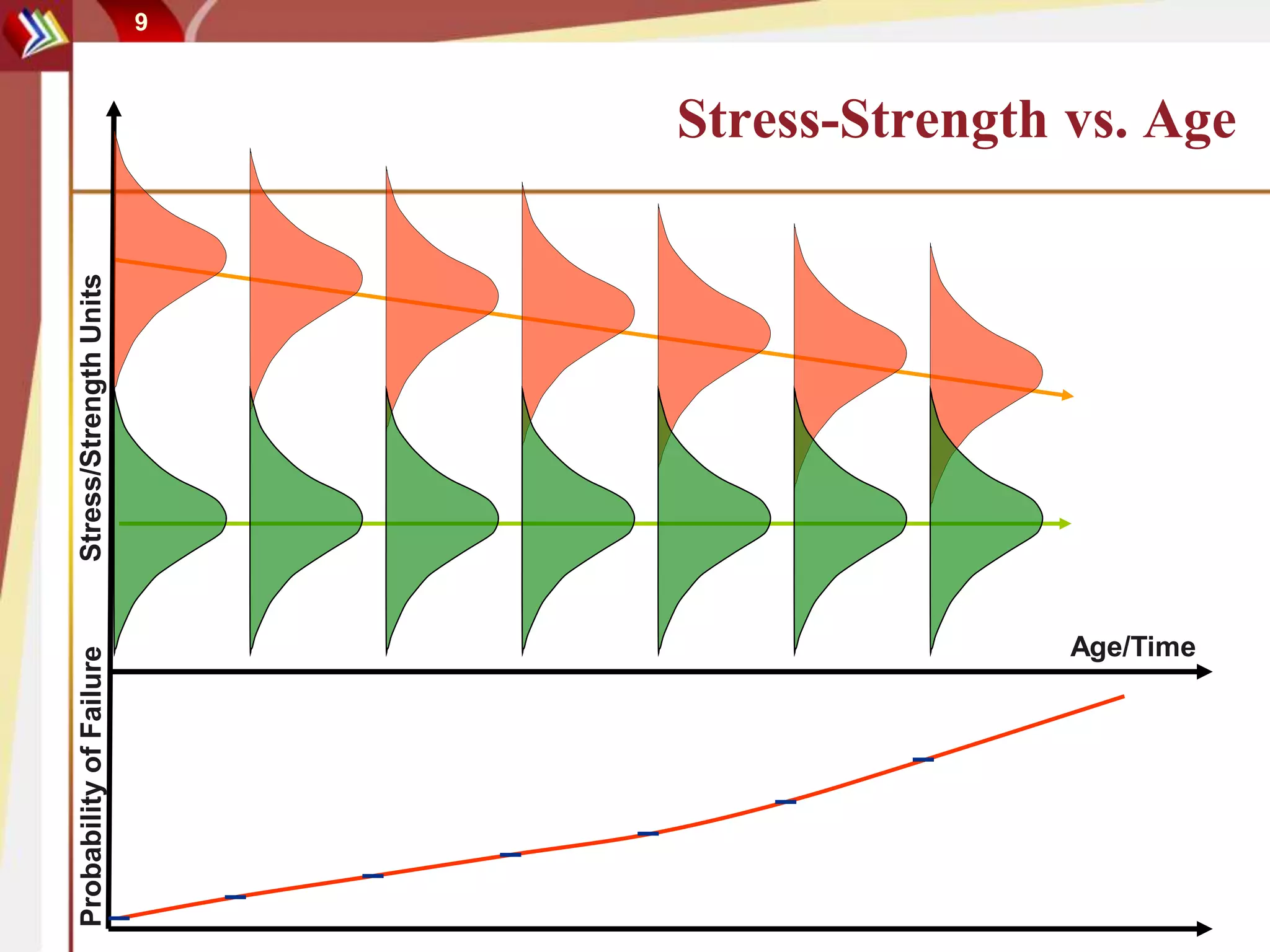

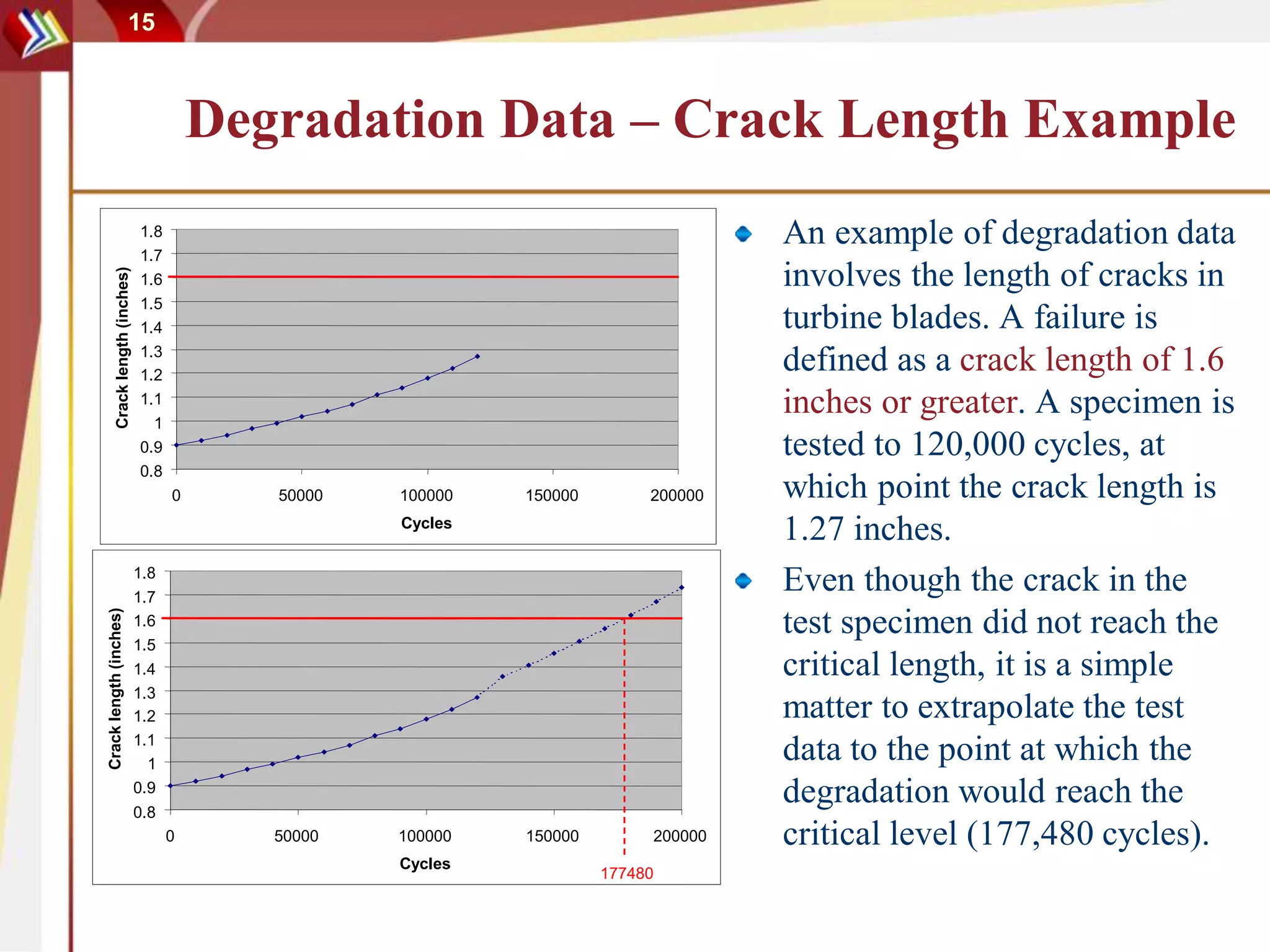

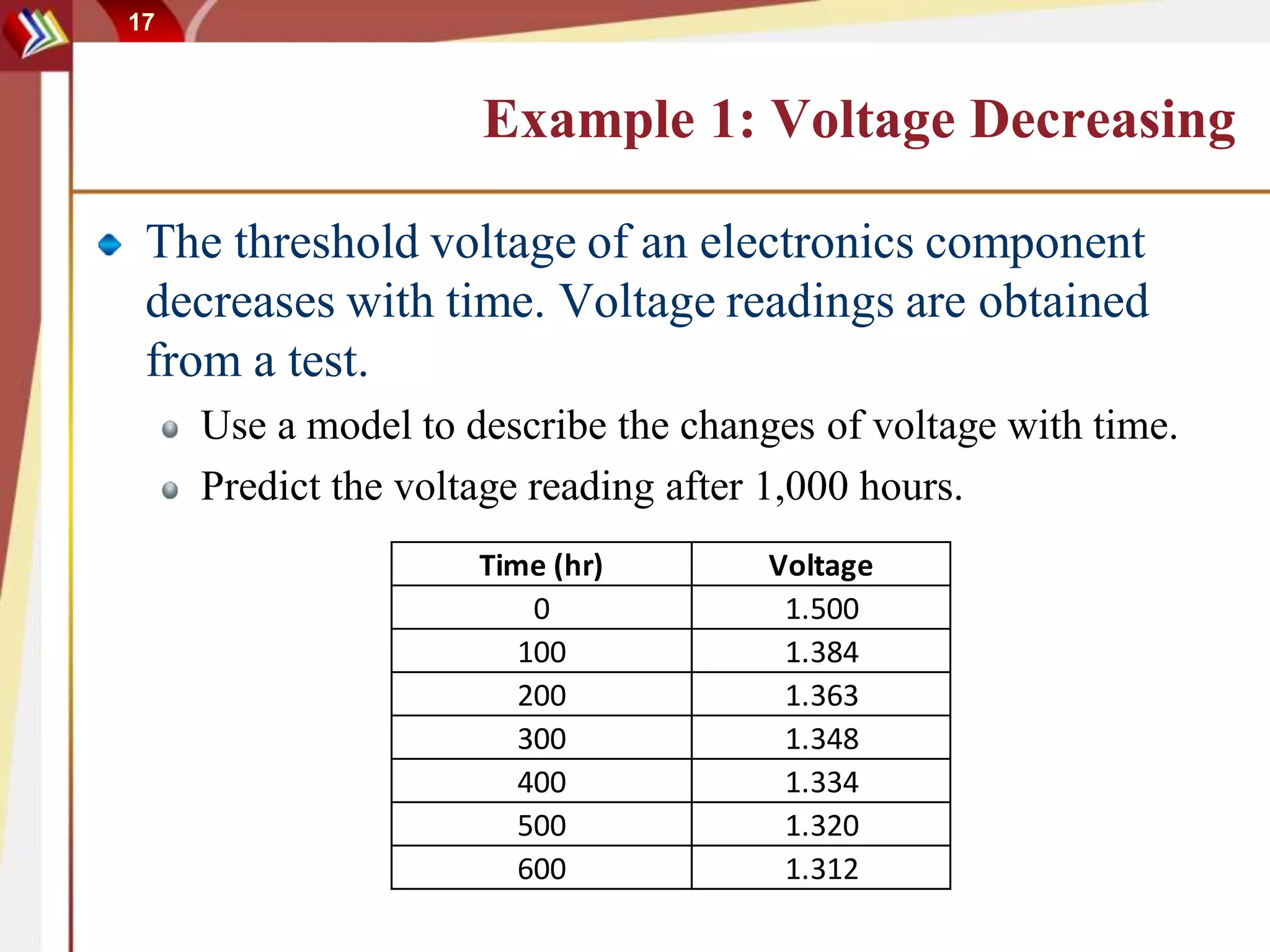

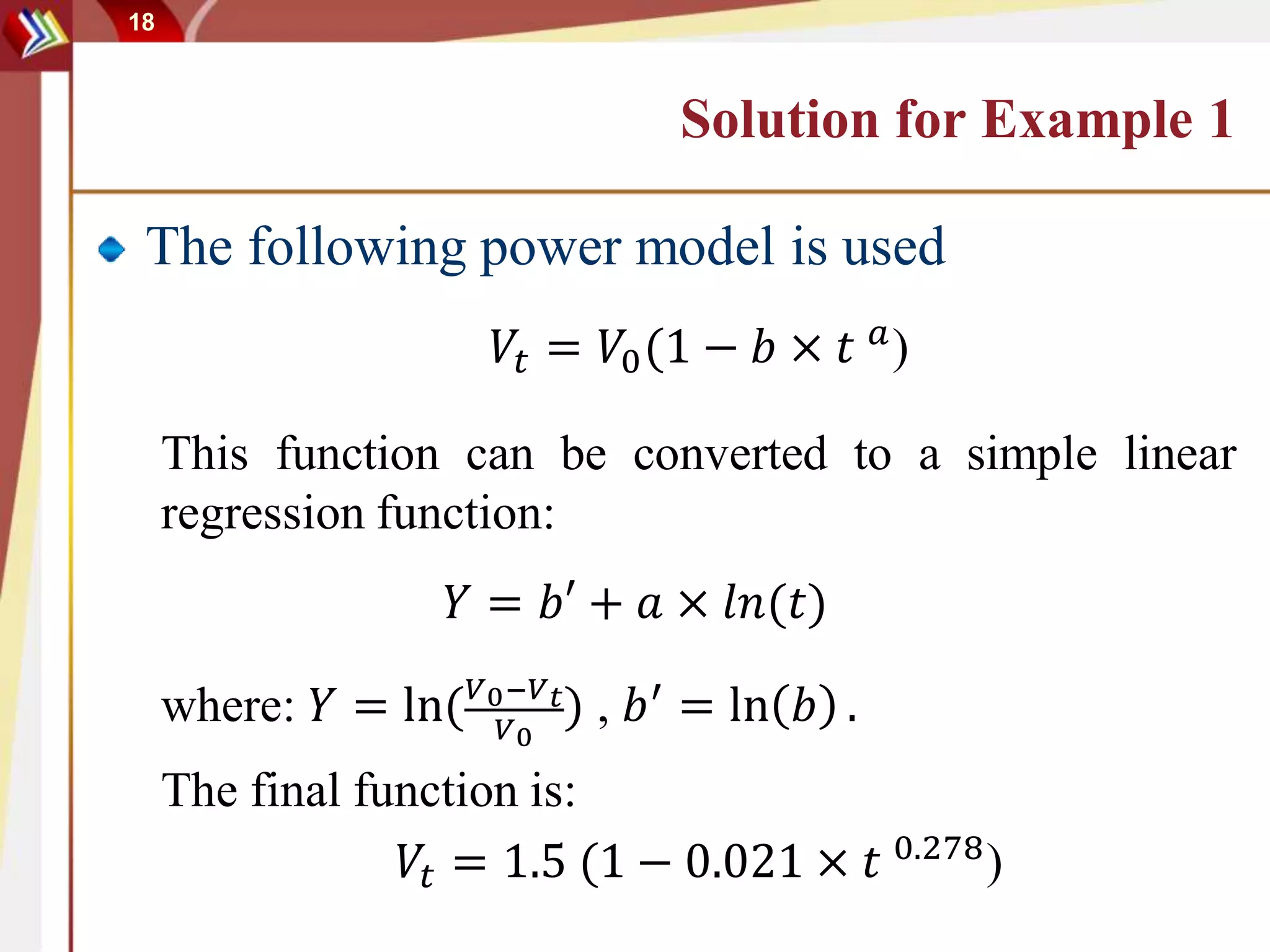

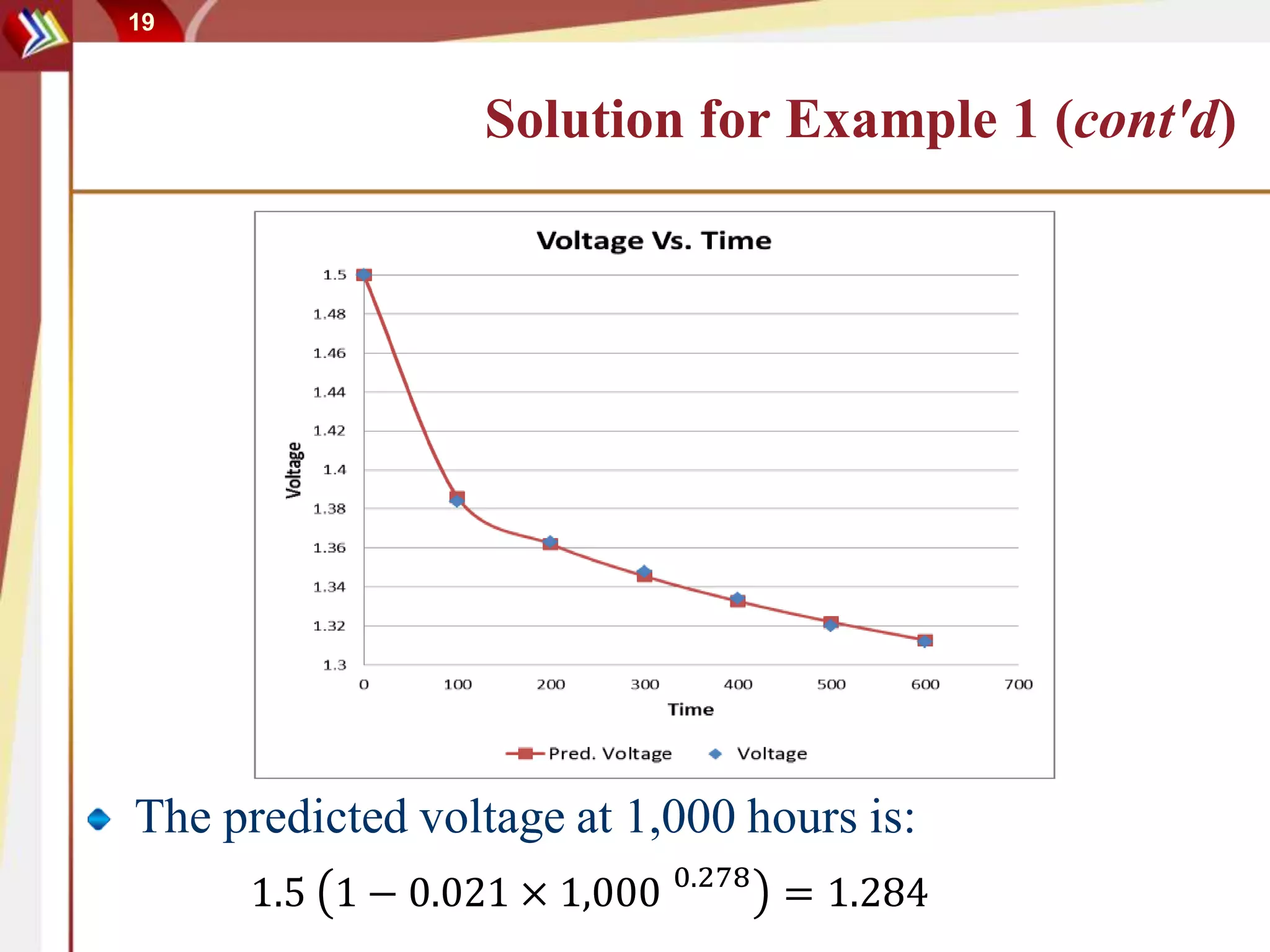

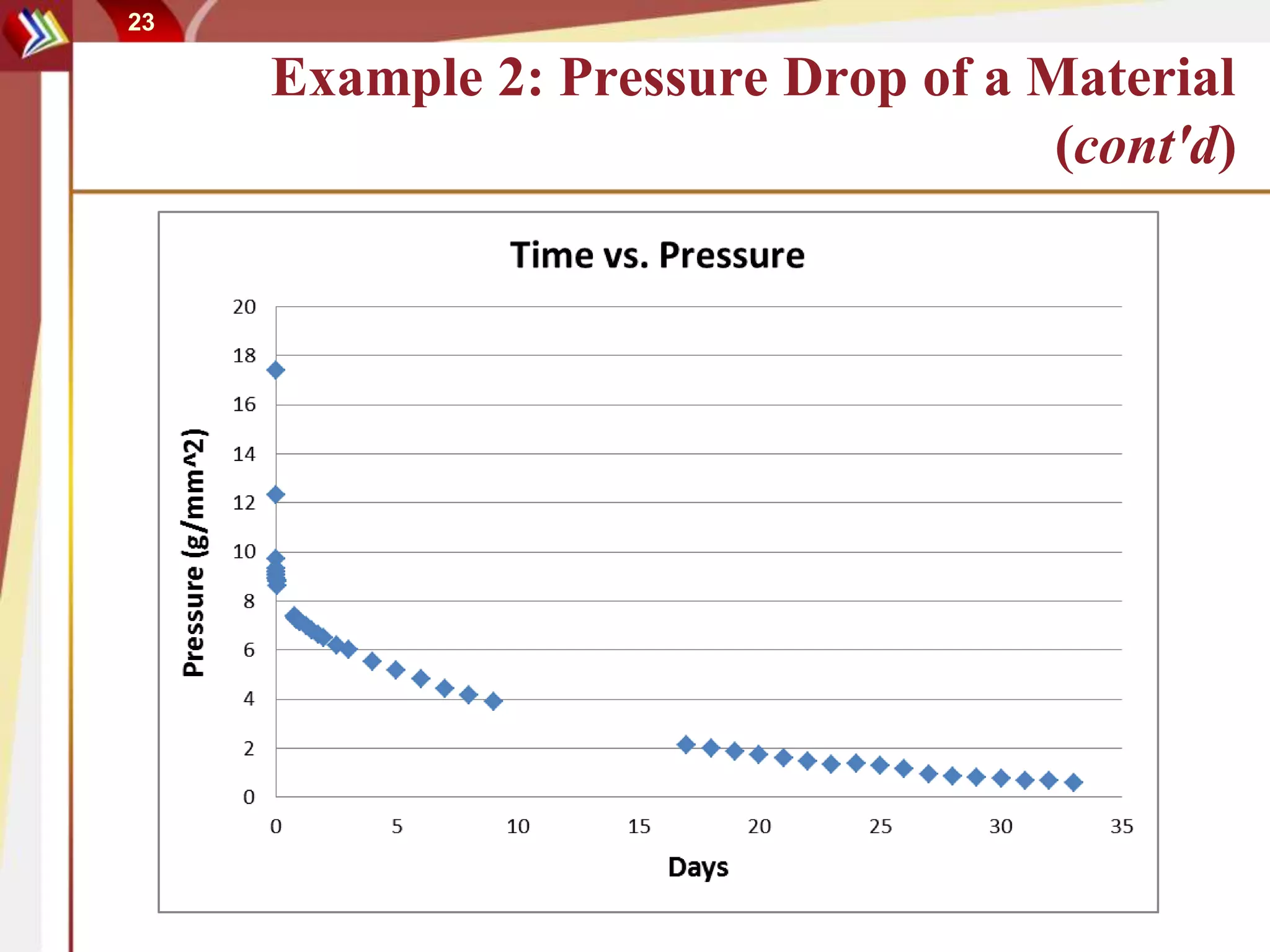

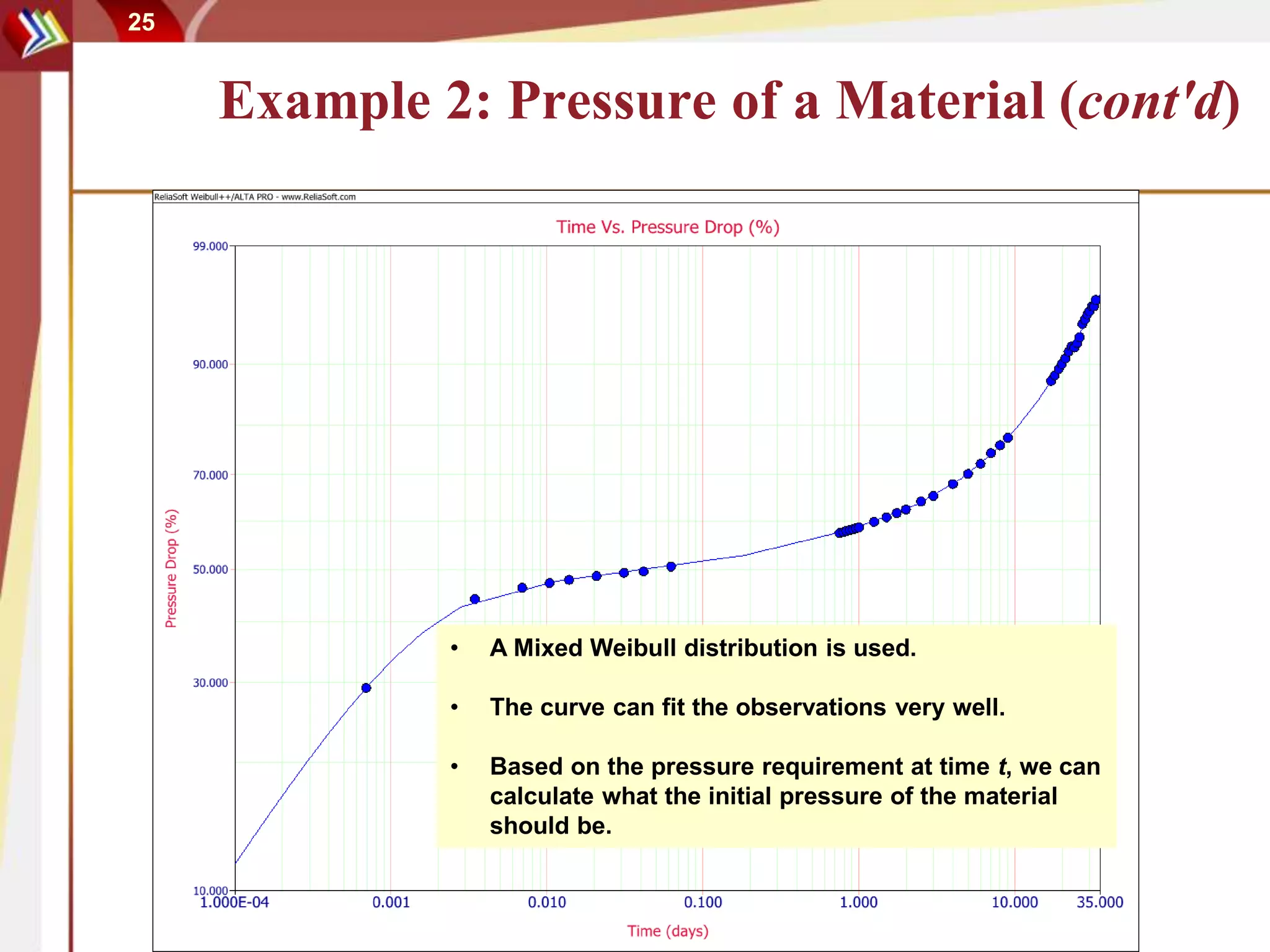

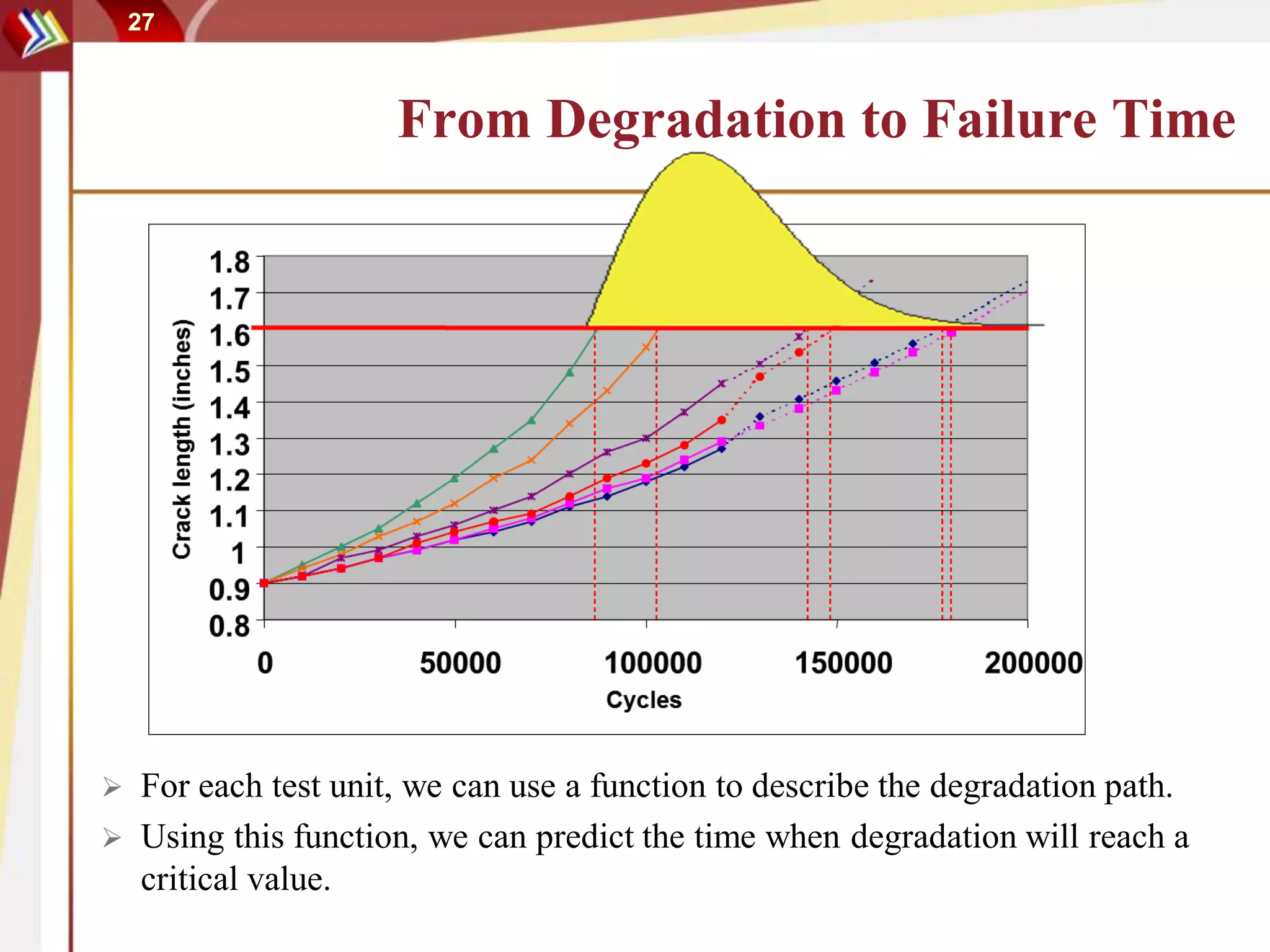

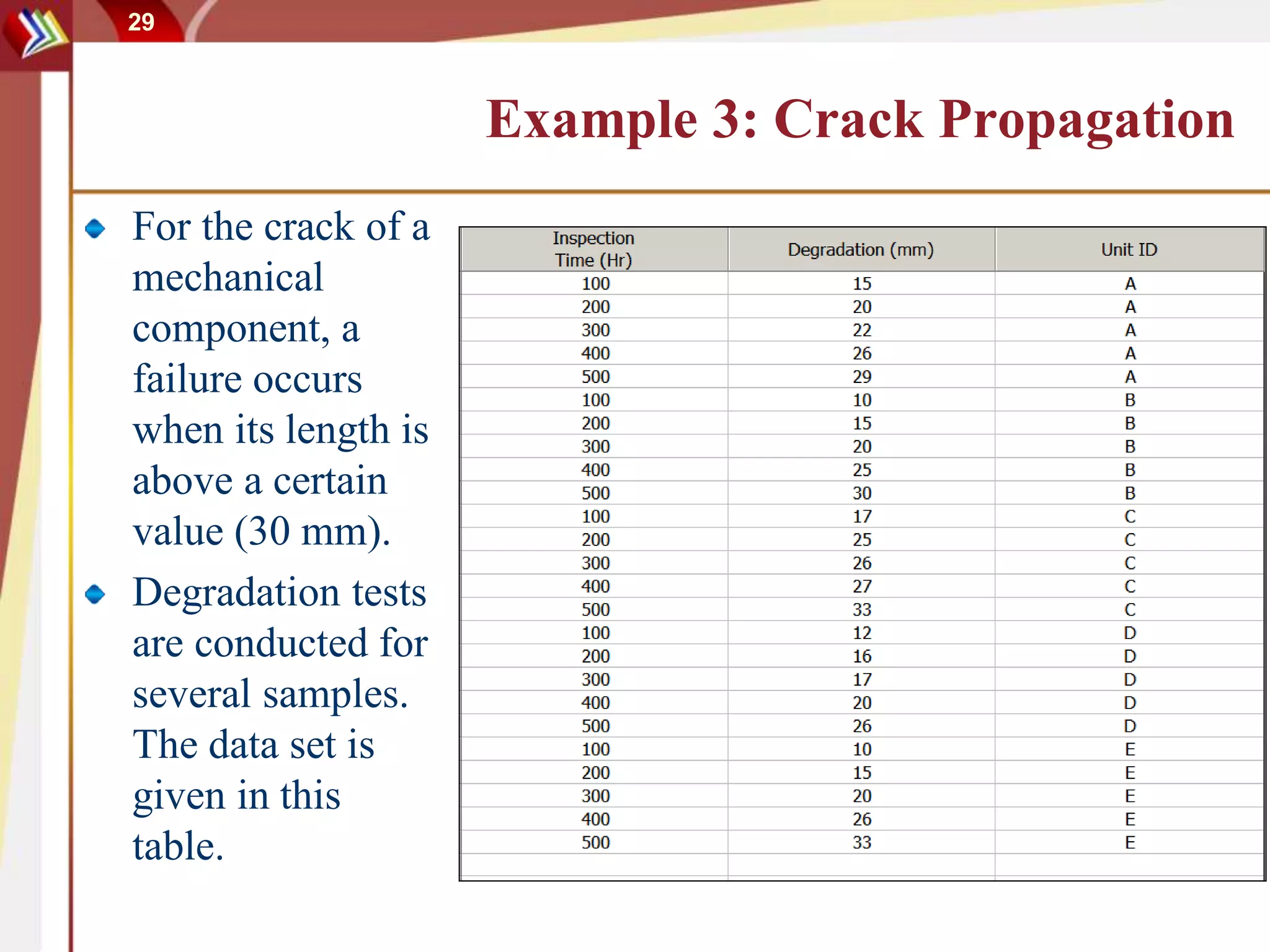

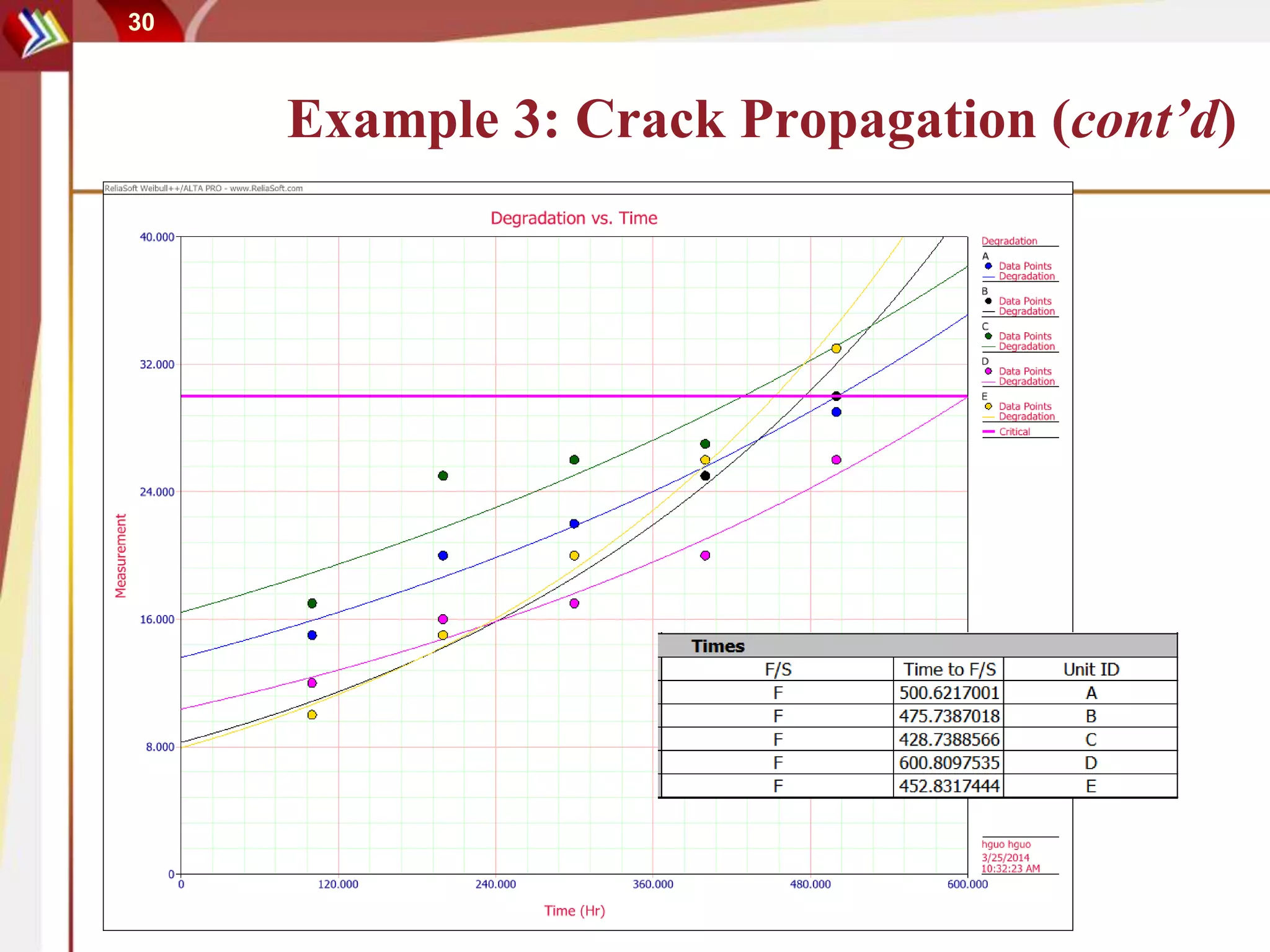

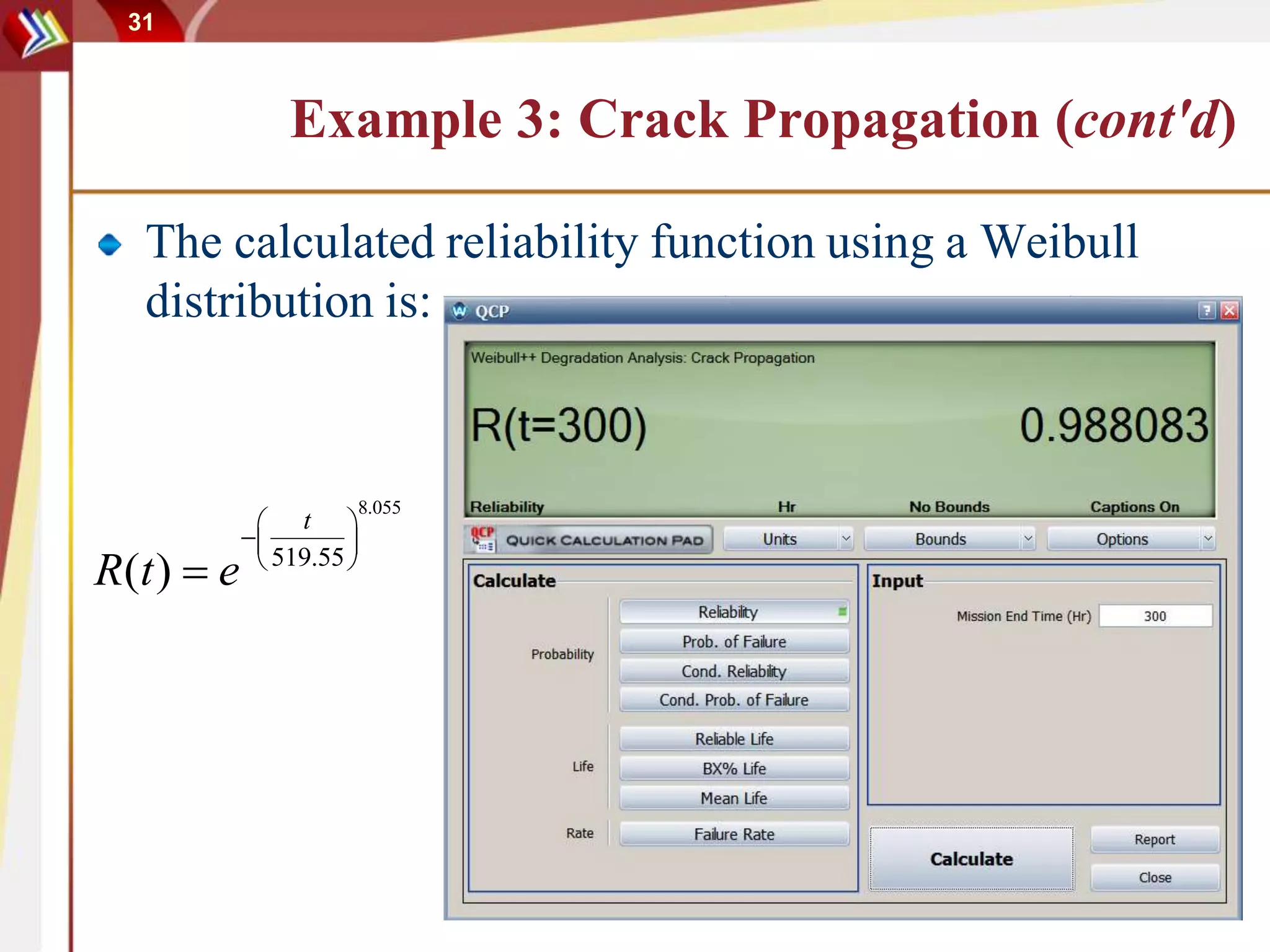

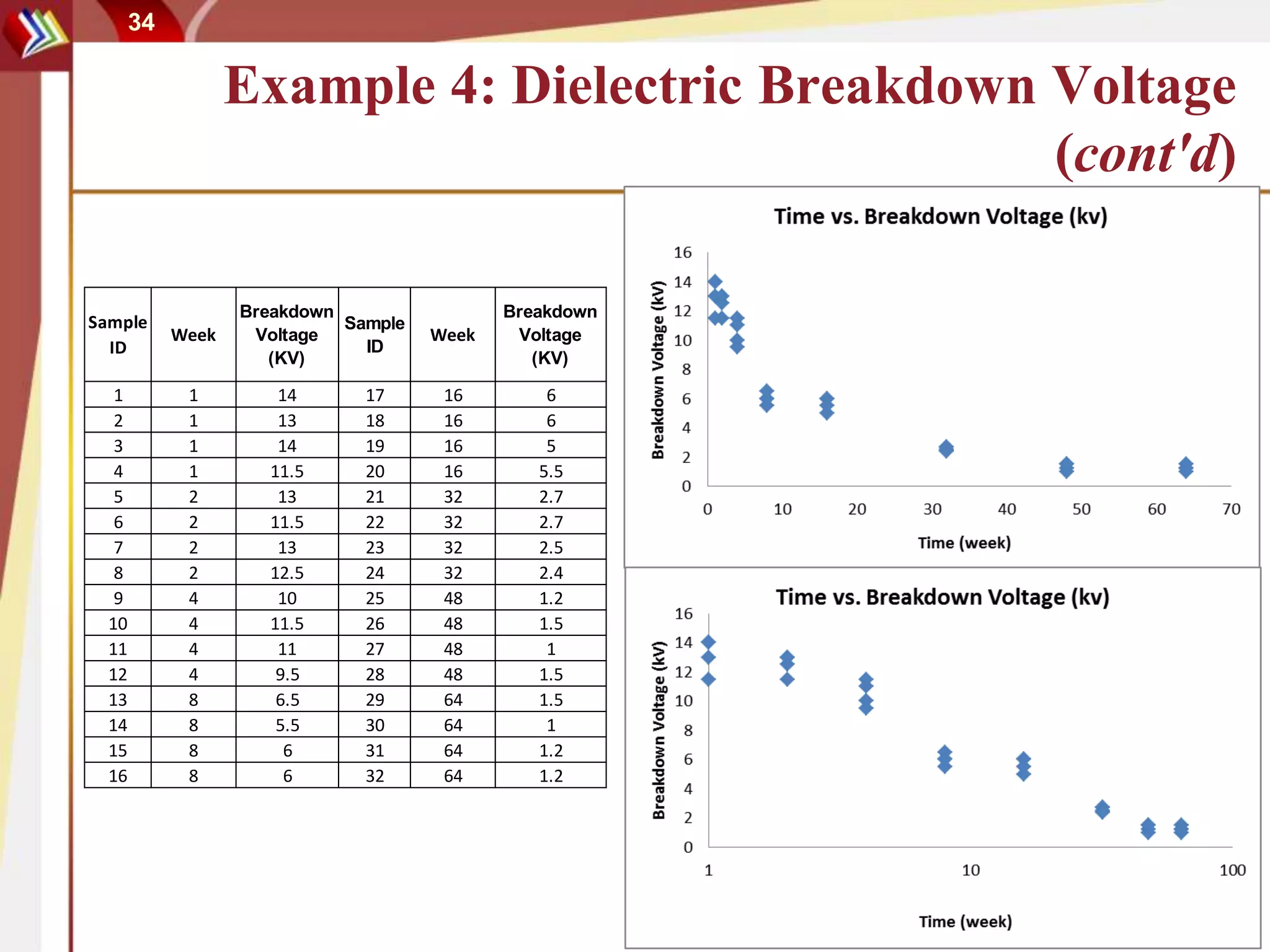

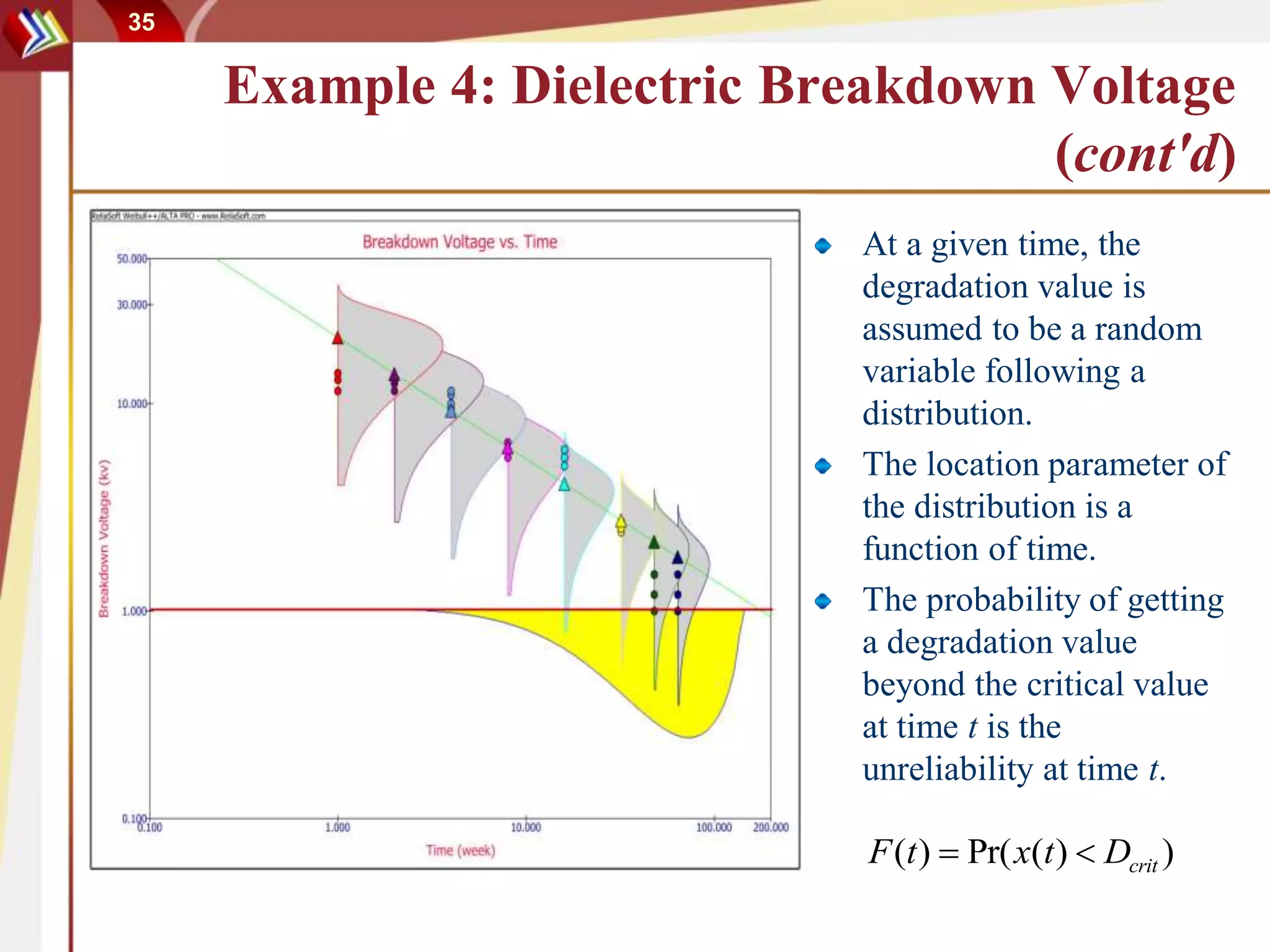

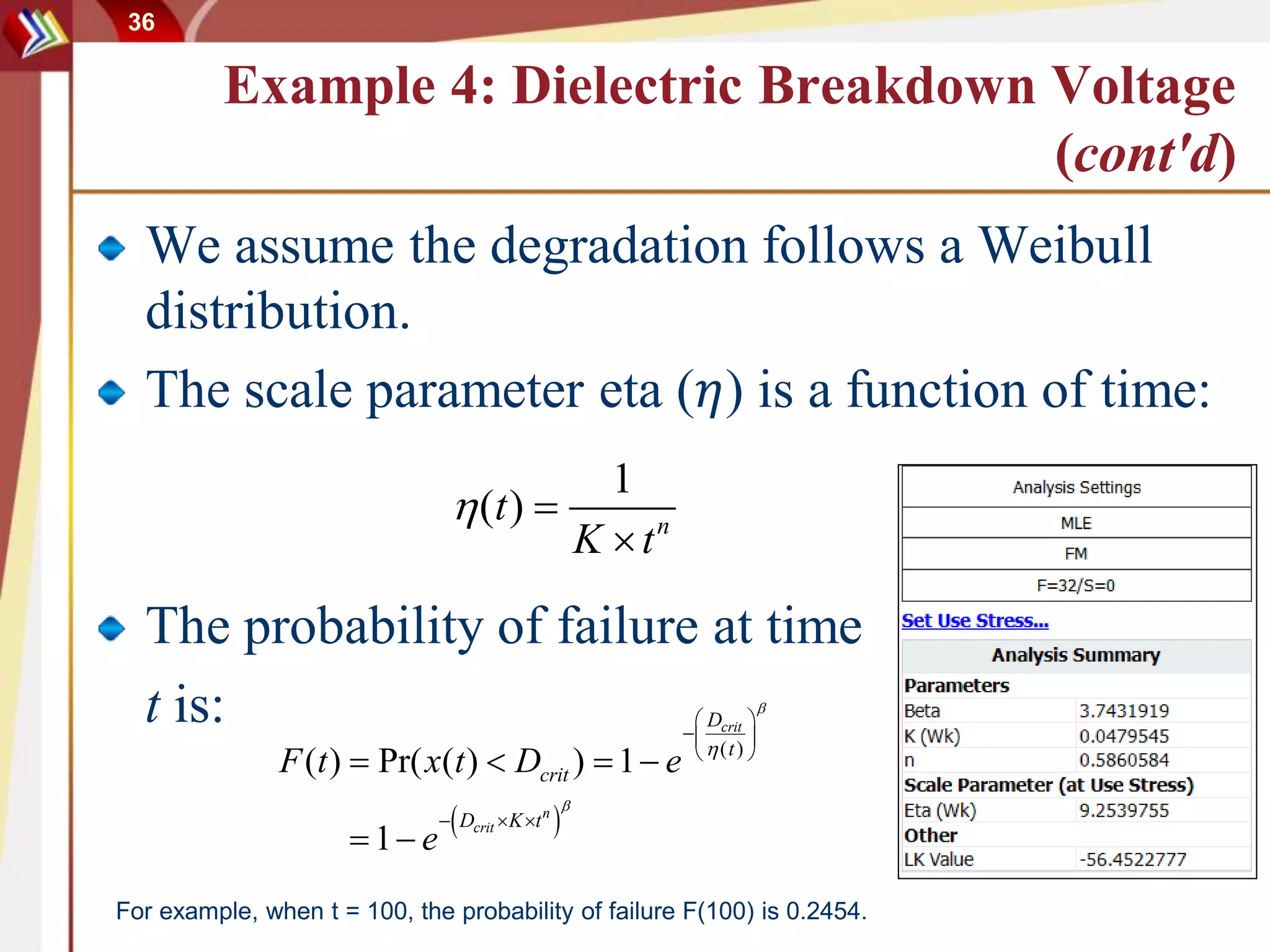

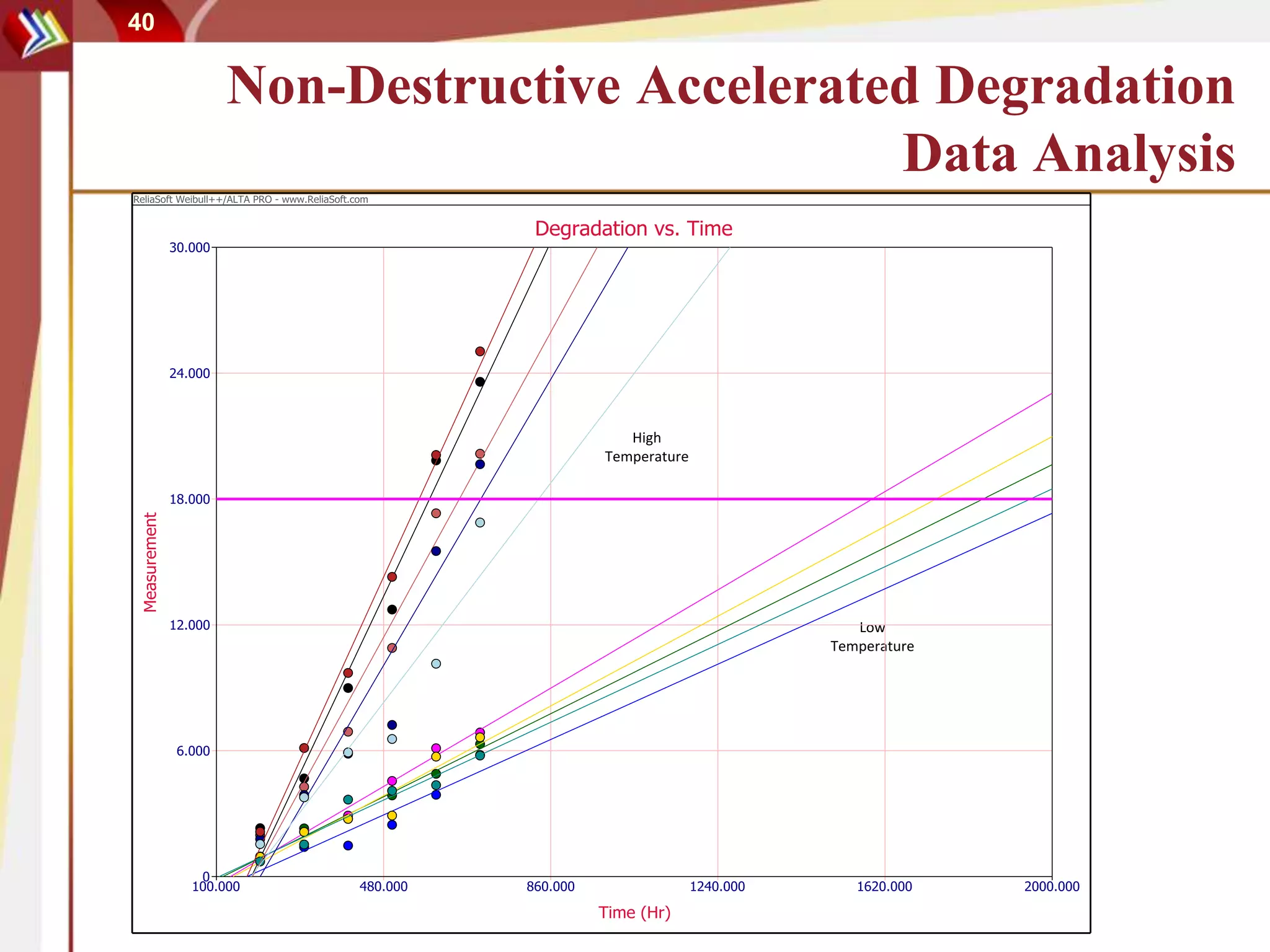

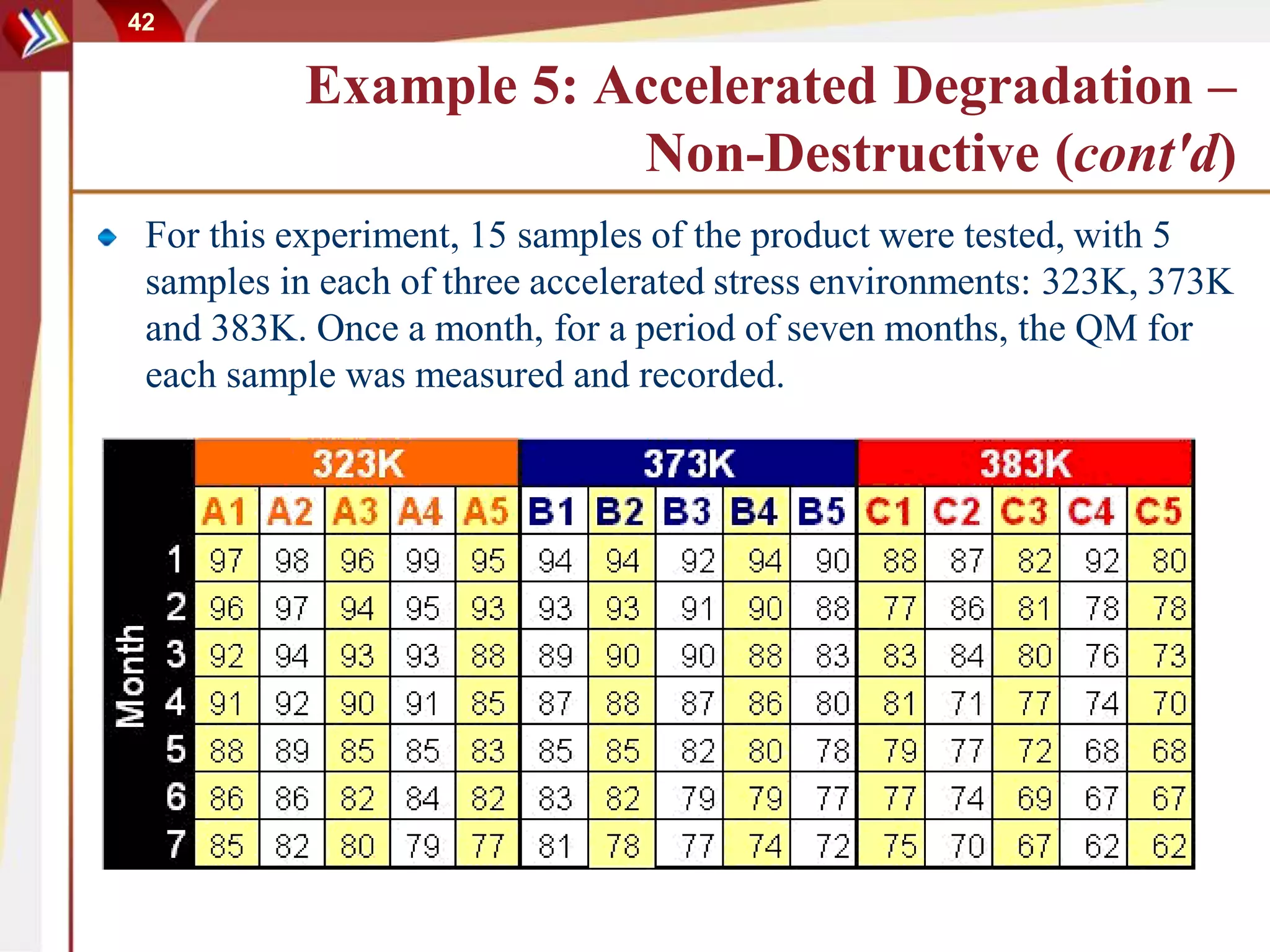

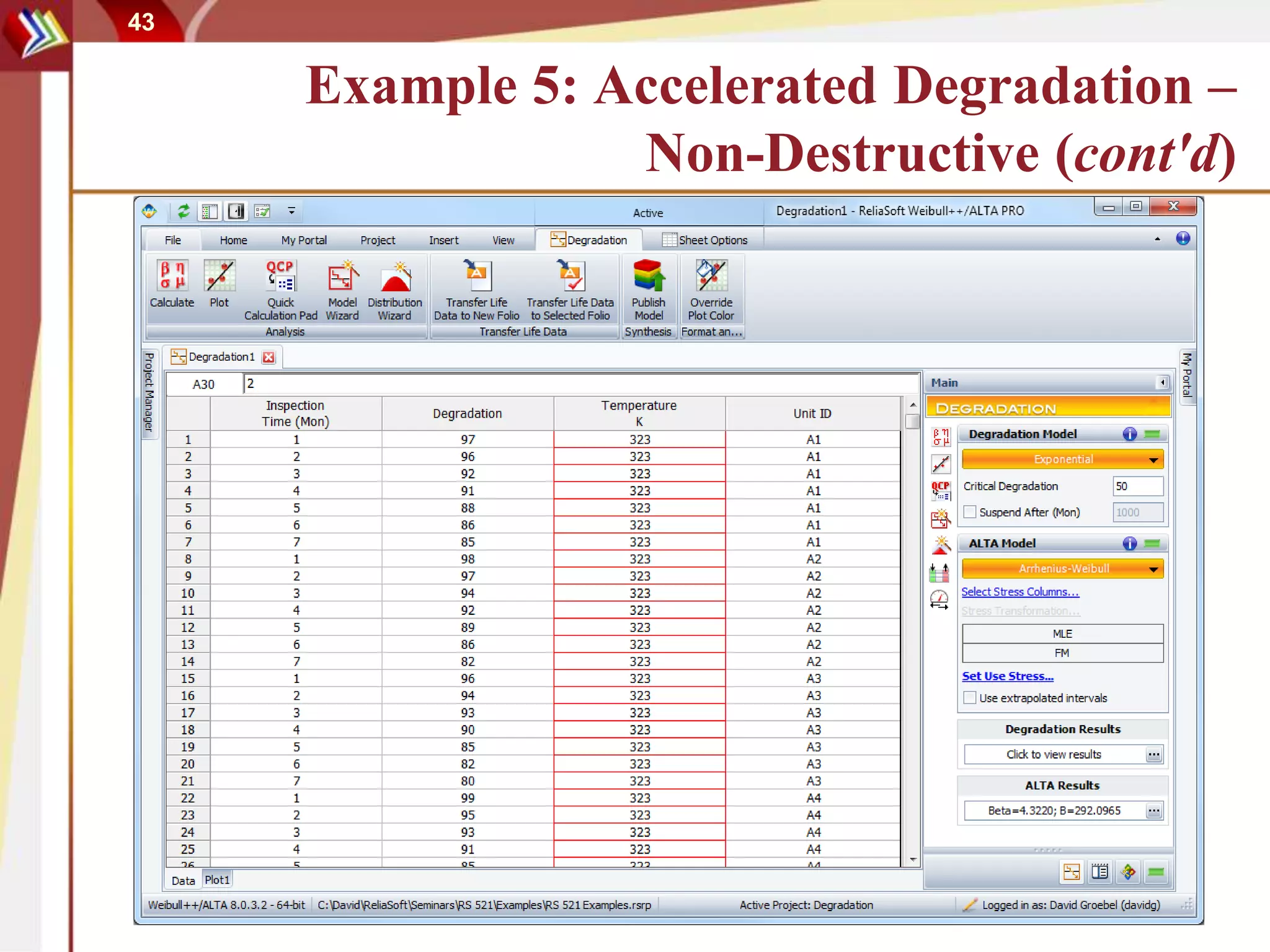

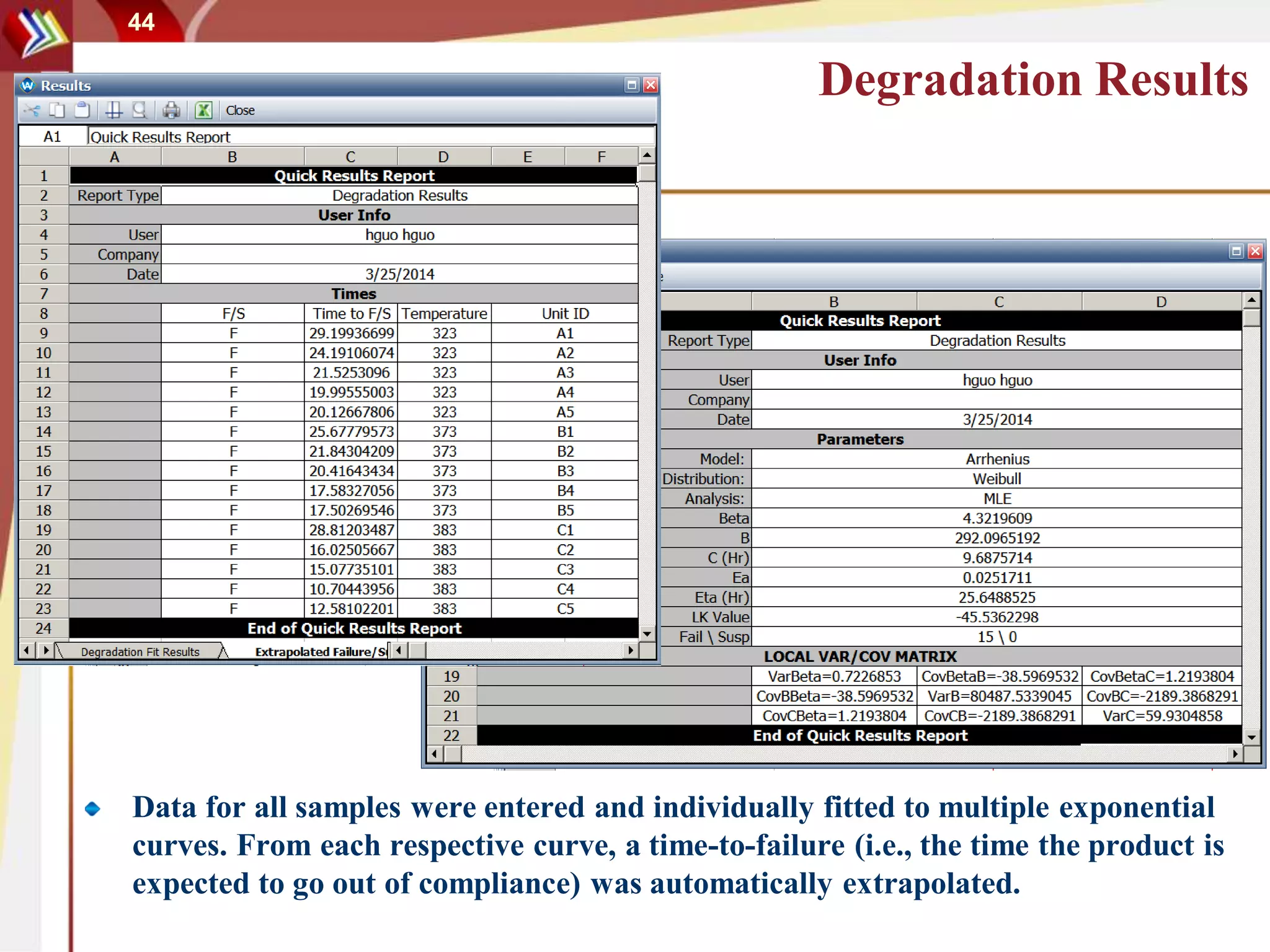

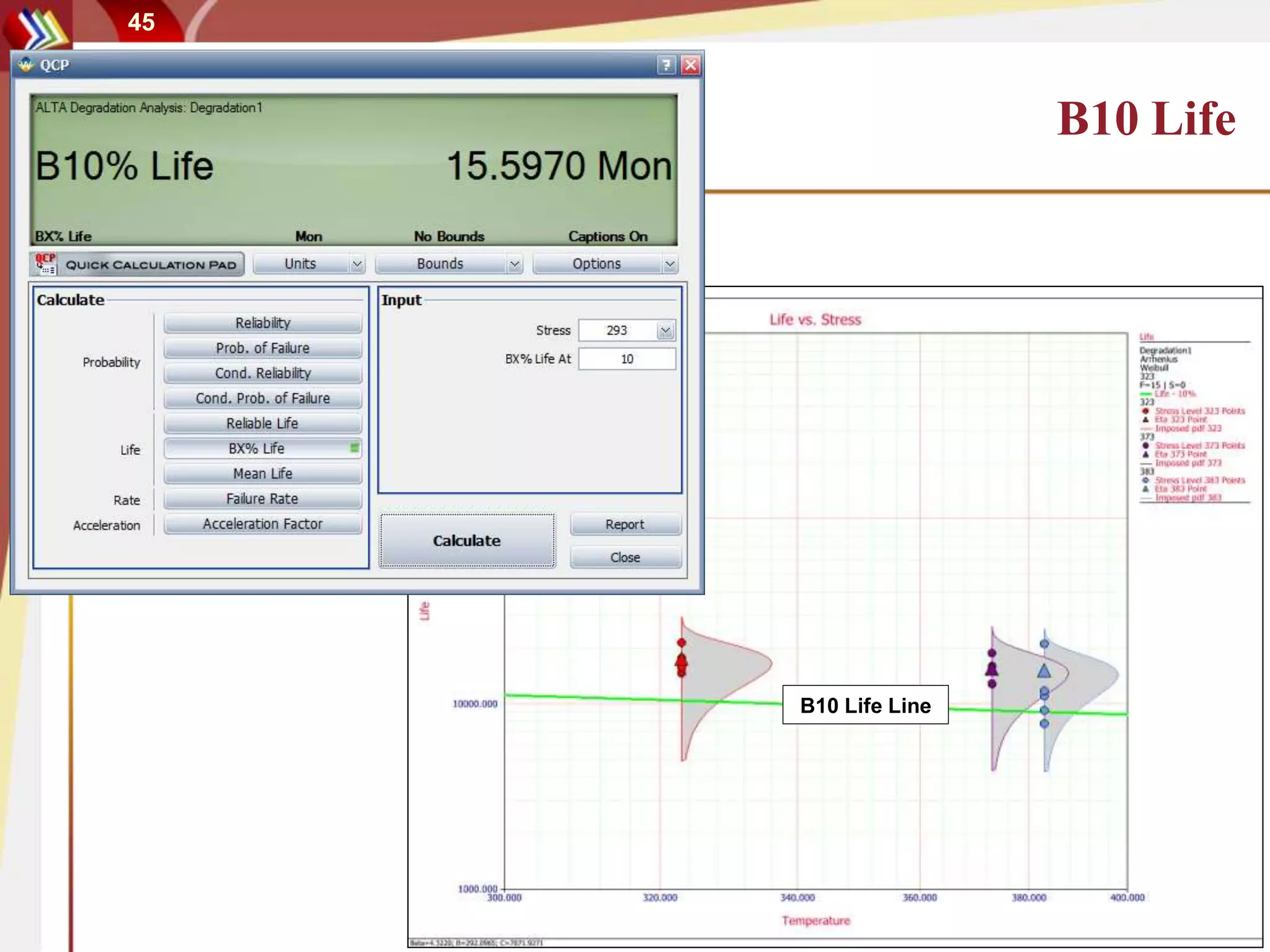

This document discusses using degradation data to model reliability and predict failure times. It begins by explaining how failures can be caused by degradation over time in mechanical components and integrated circuits. Examples of degradation mechanisms like creep, fatigue, and corrosion are provided. The document then discusses using non-destructive and destructive inspection of degradation parameters to build models and predict reliability. Accelerated degradation testing is also covered as a way to quickly generate degradation data under elevated stress conditions. Overall, the document provides an overview of modeling reliability using degradation data and predicting failure times based on degradation paths.