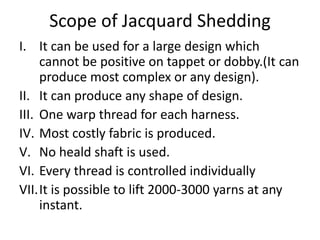

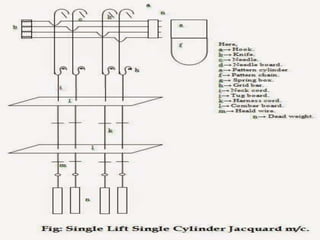

The document is a detailed presentation on the Single Lift Single Cylinder (SLSC) Jacquard system, highlighting its capabilities and advantages over traditional shedding systems like cam and dobby. SLSC Jacquard allows for the independent control of individual yarns, enabling the production of intricate woven designs without the use of heald shafts. It provides insights into its mechanical classification, operational mechanisms, and the unique features that facilitate complex fabric creation in textile engineering.