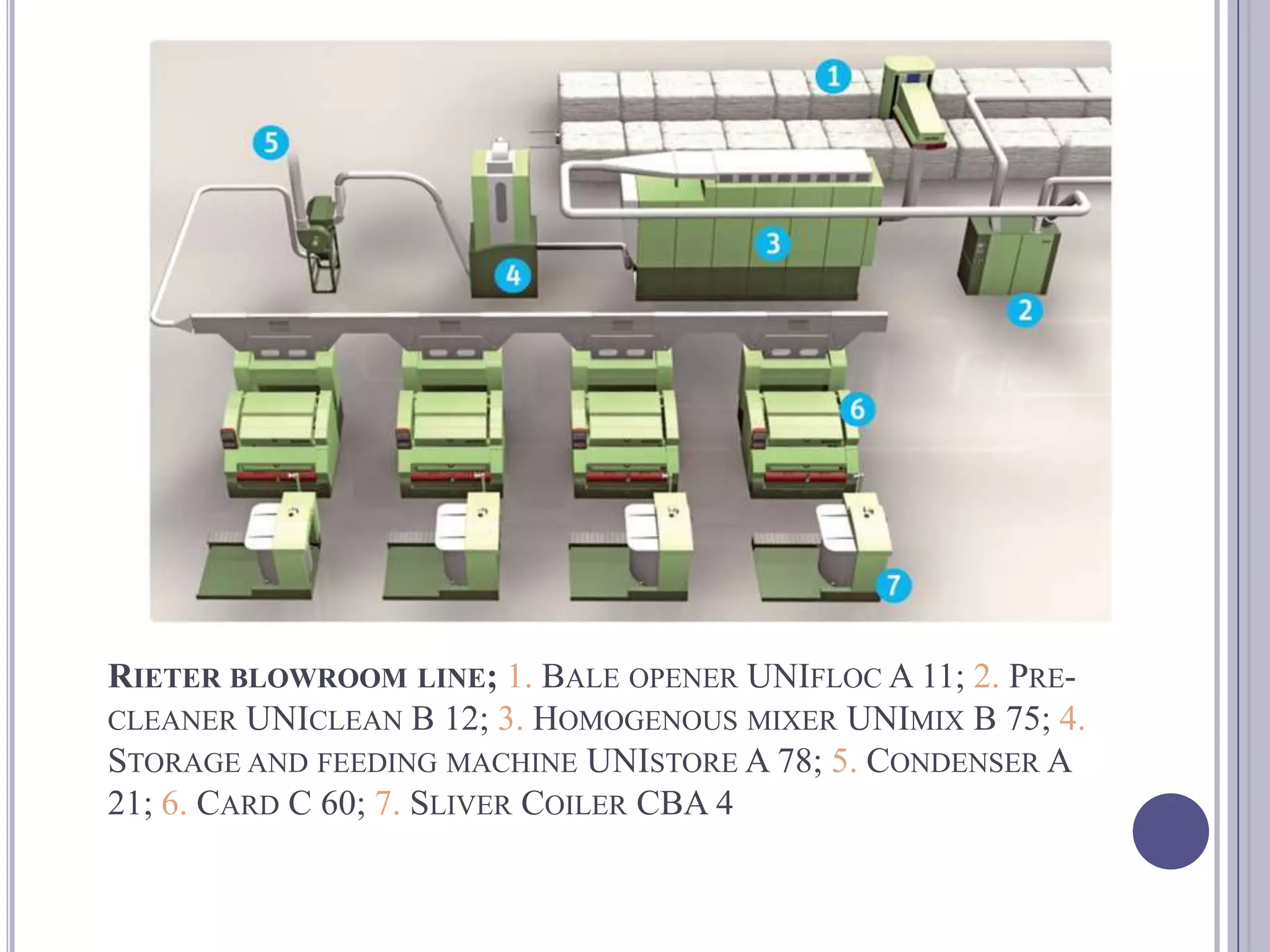

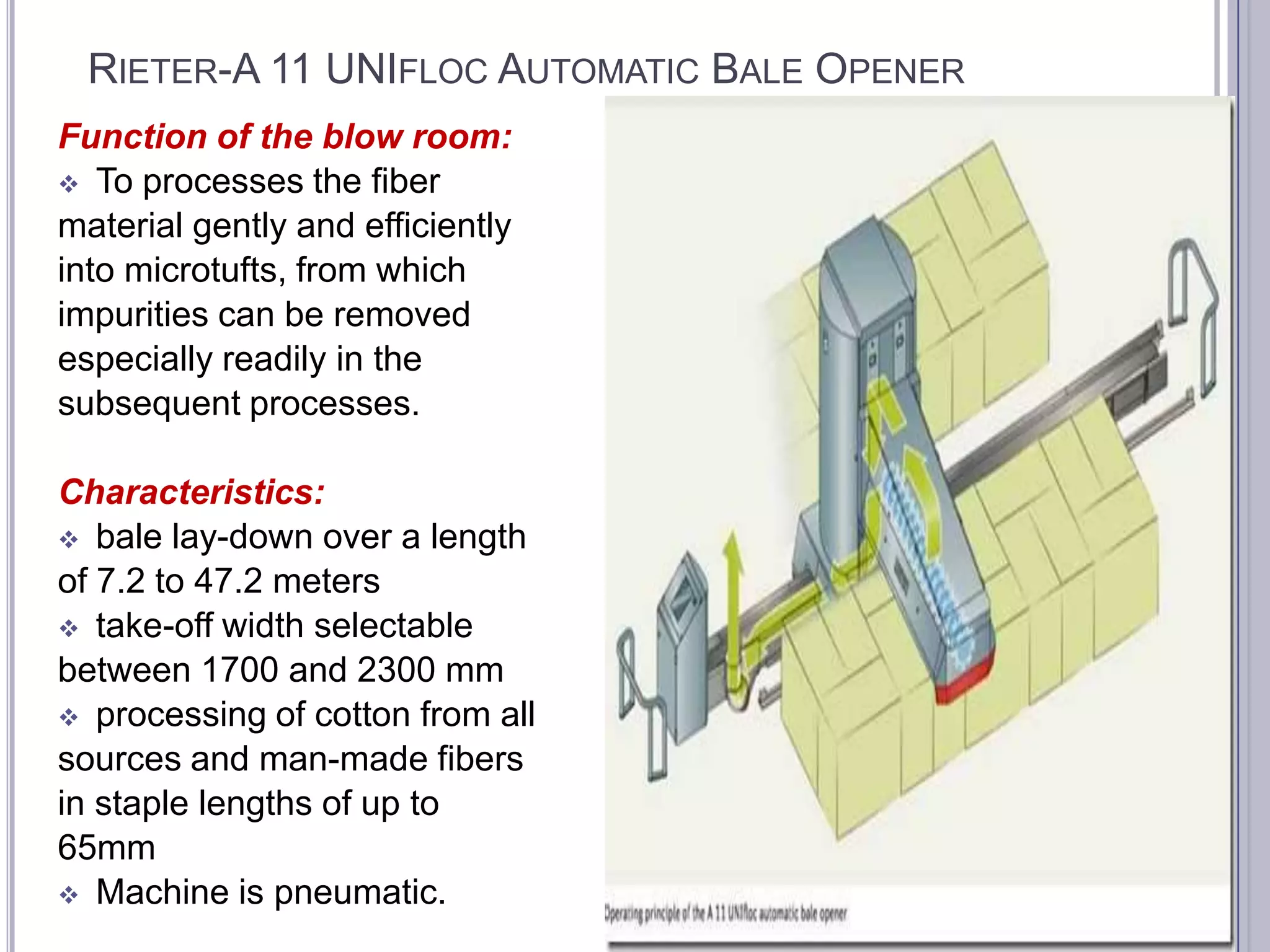

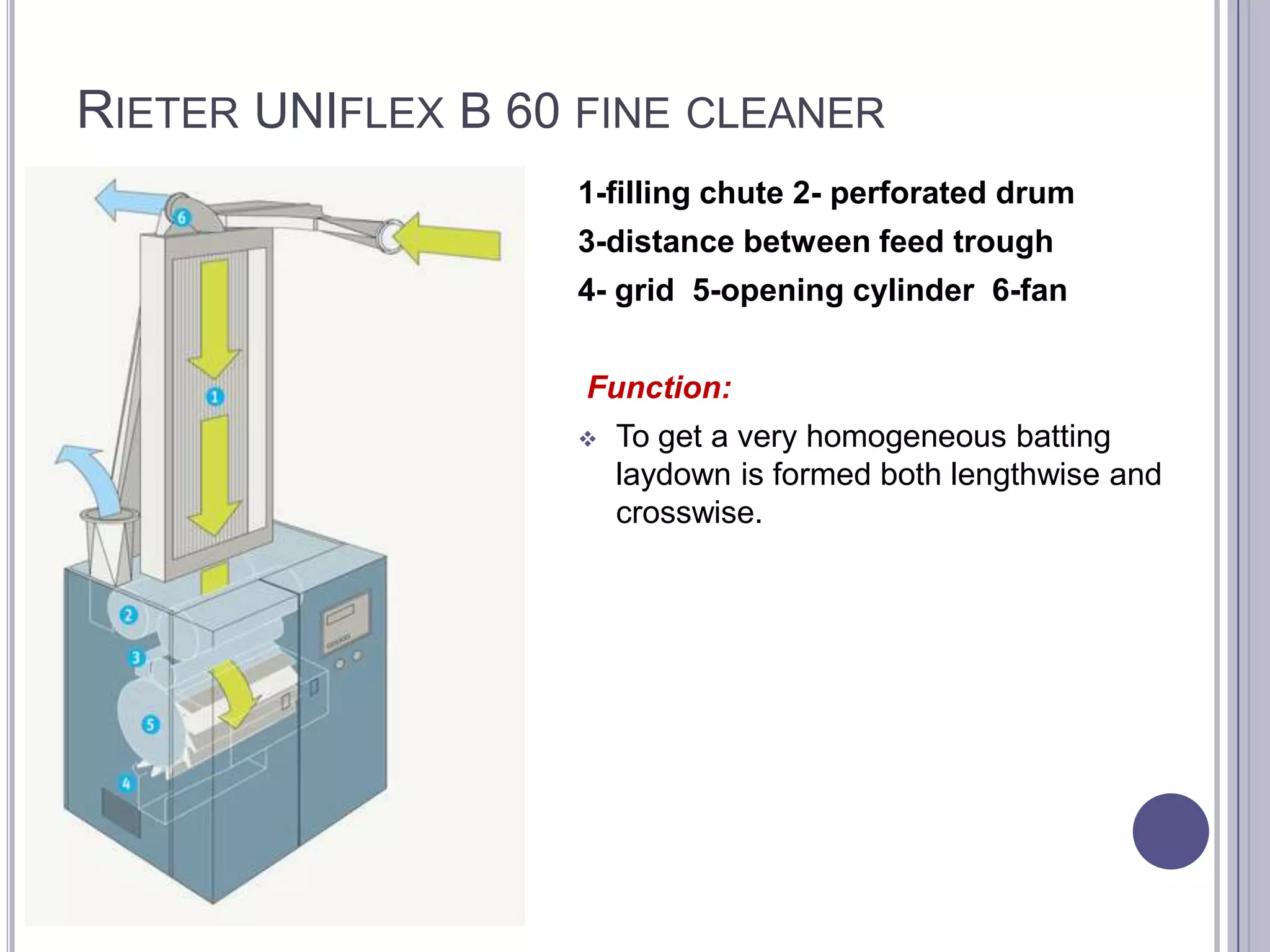

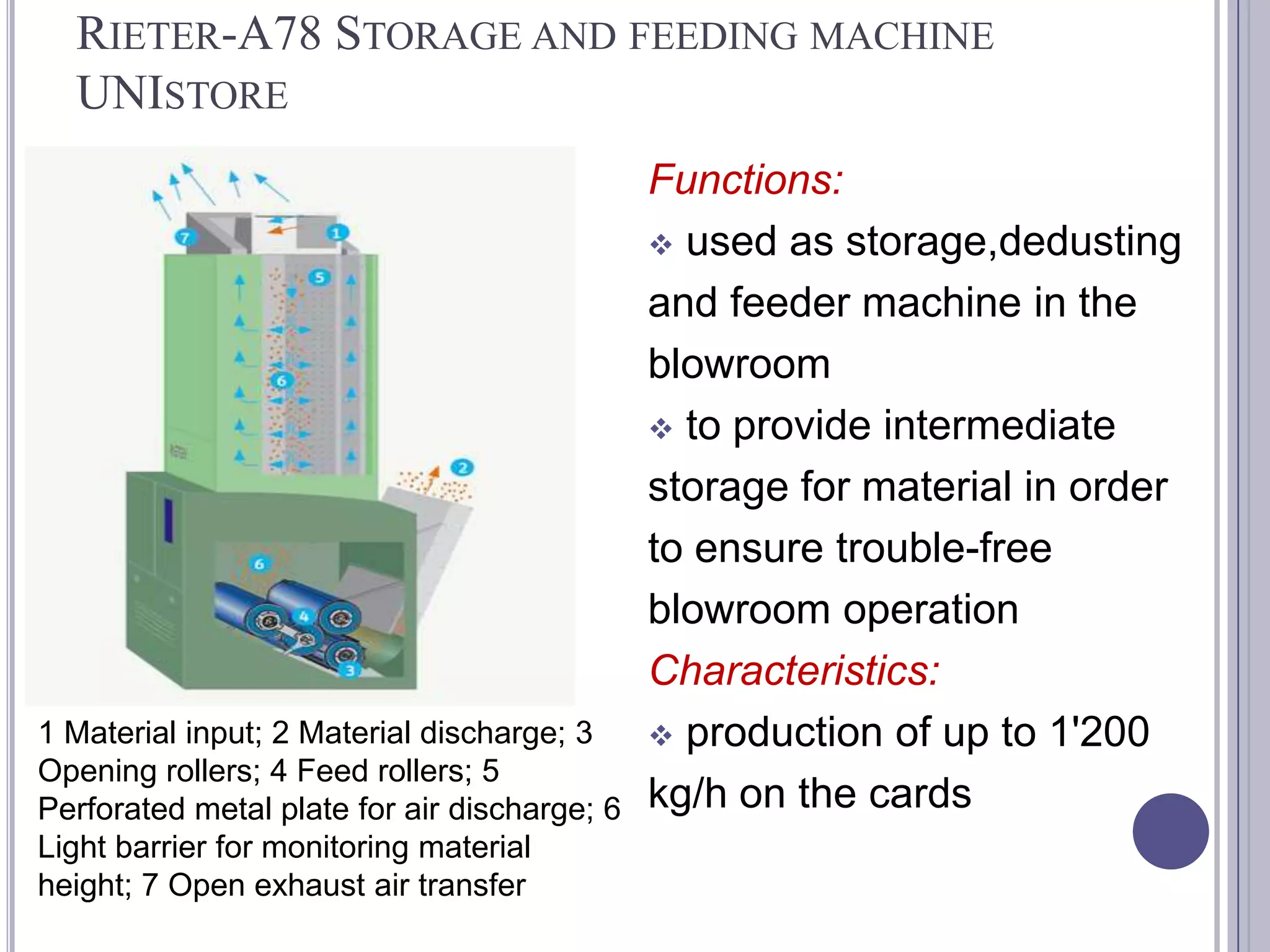

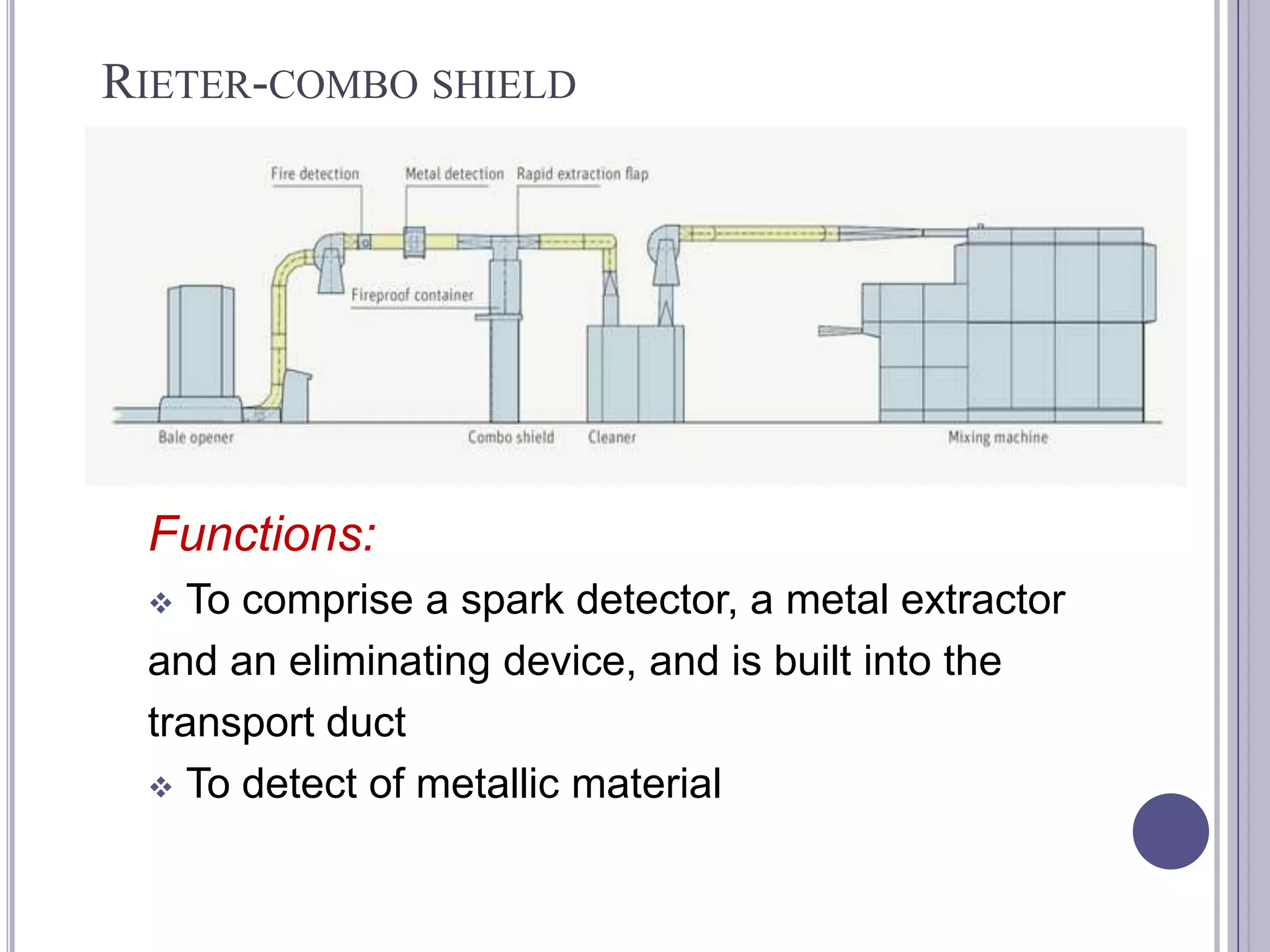

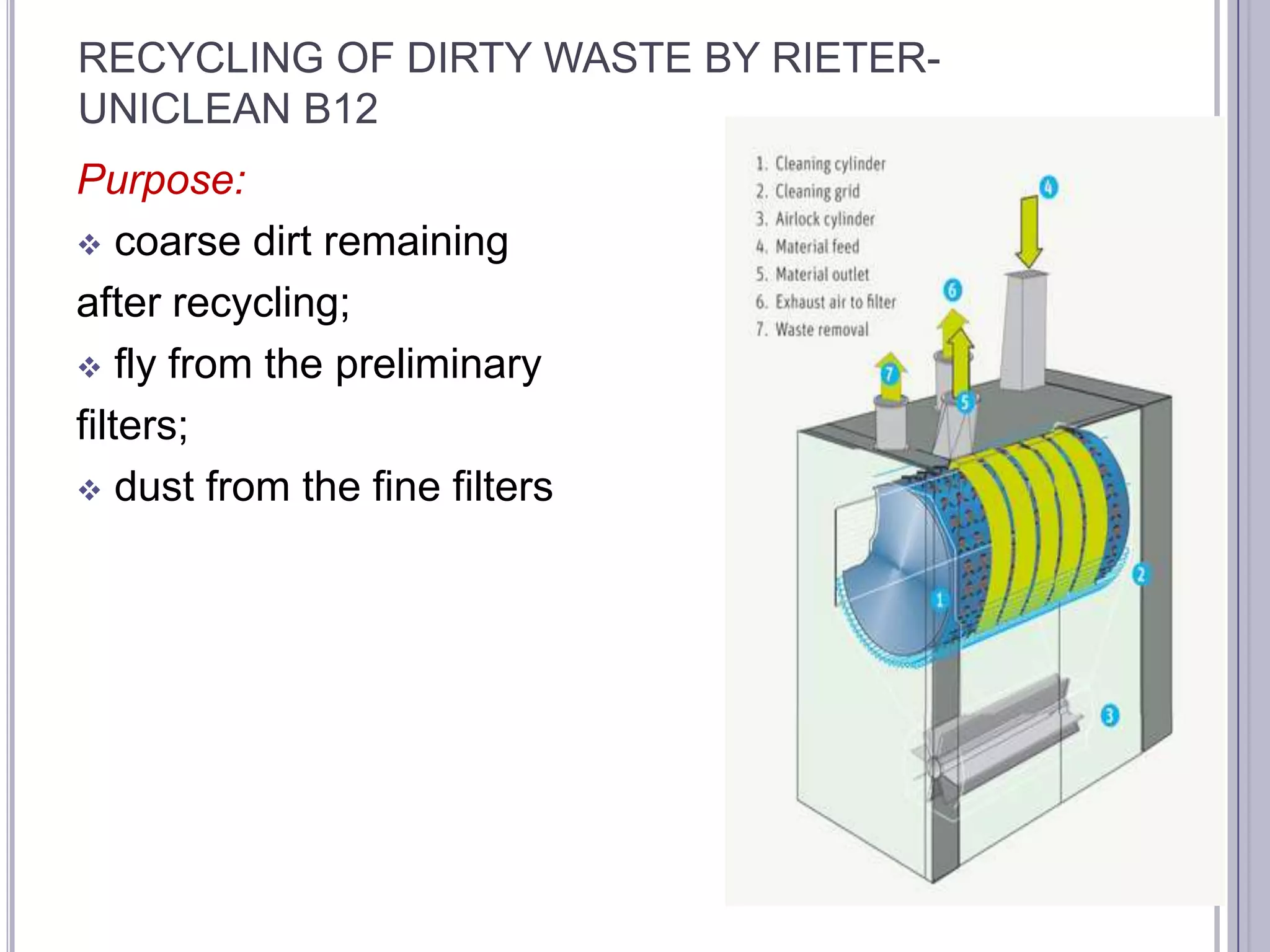

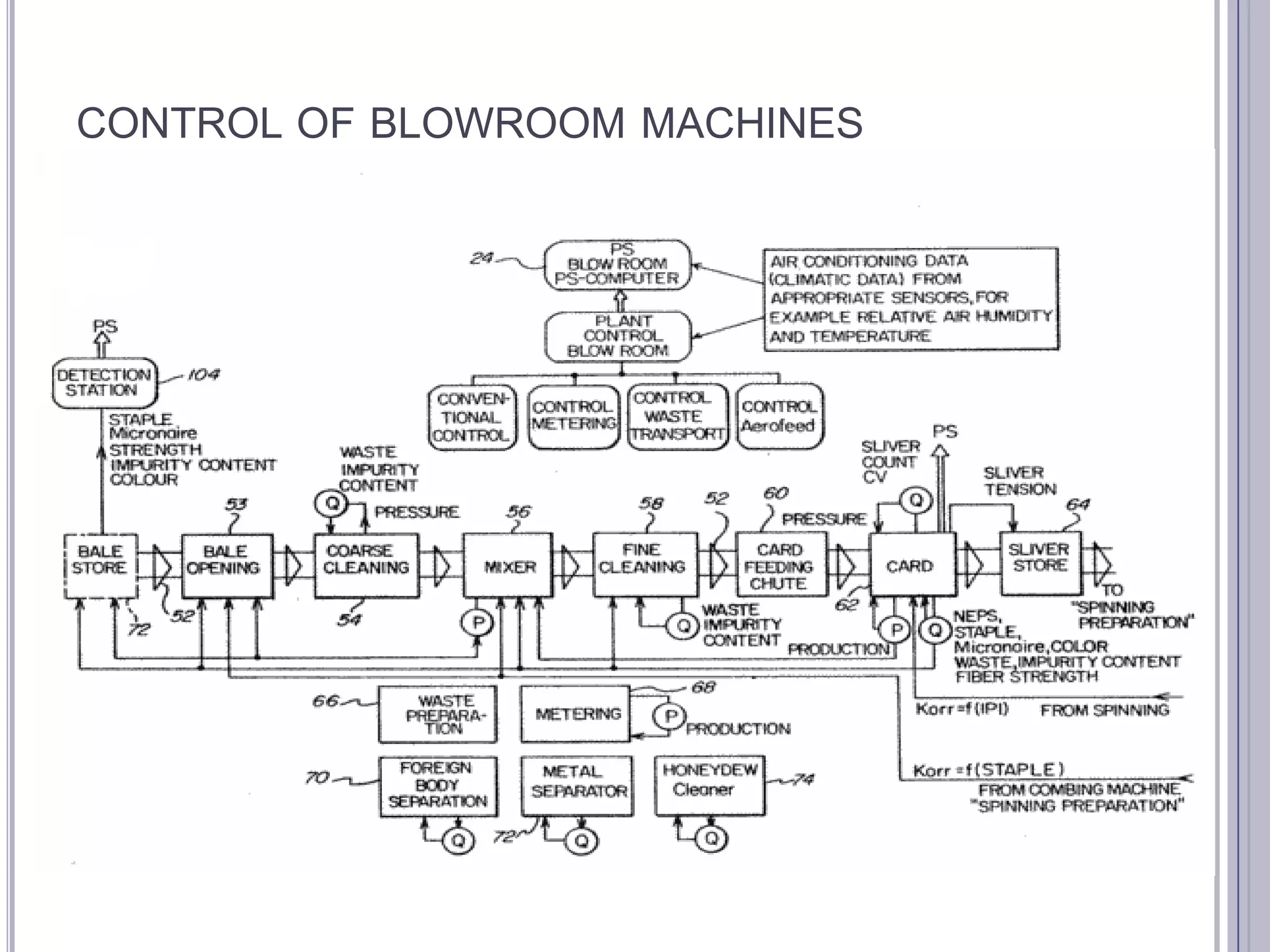

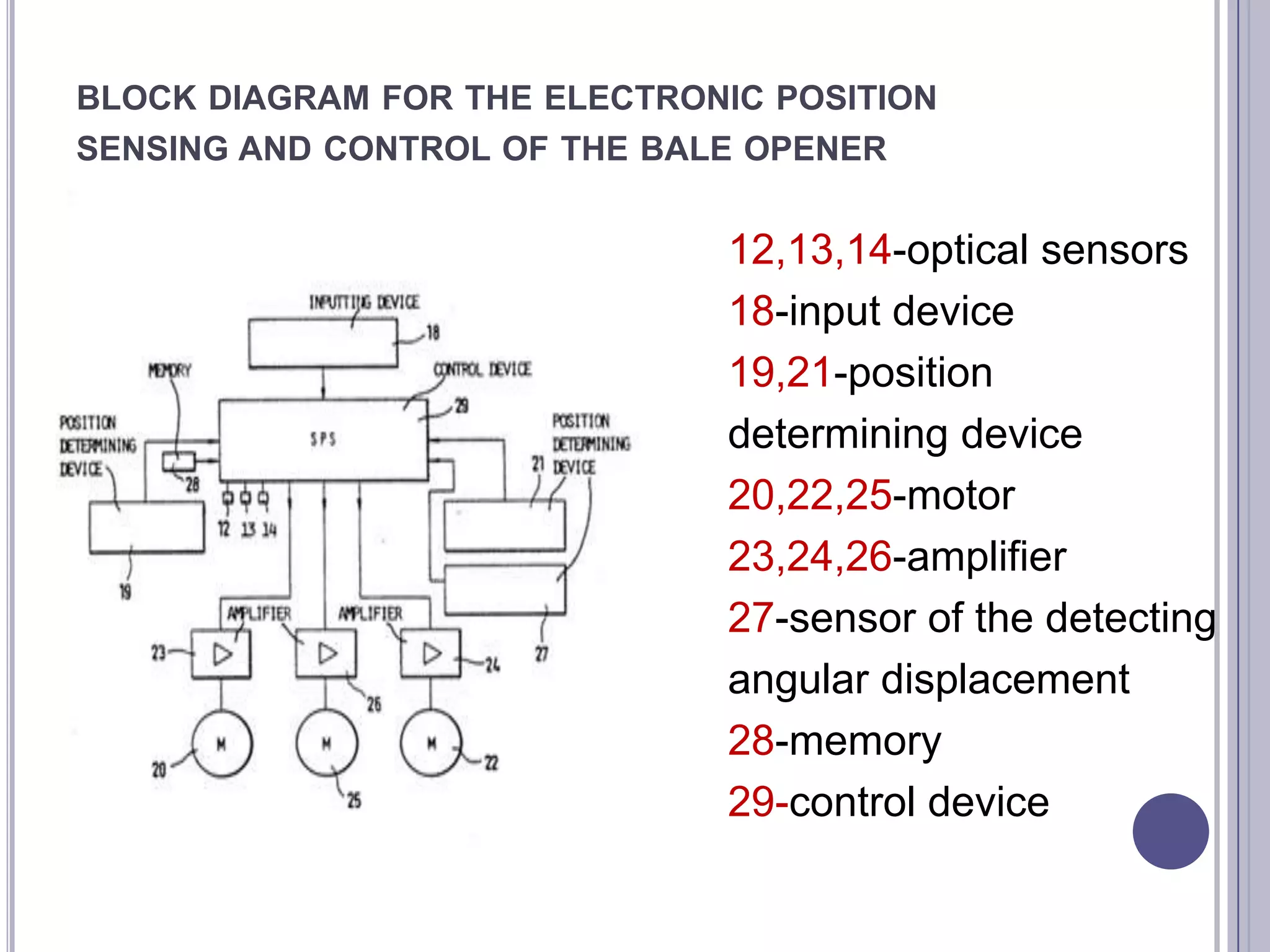

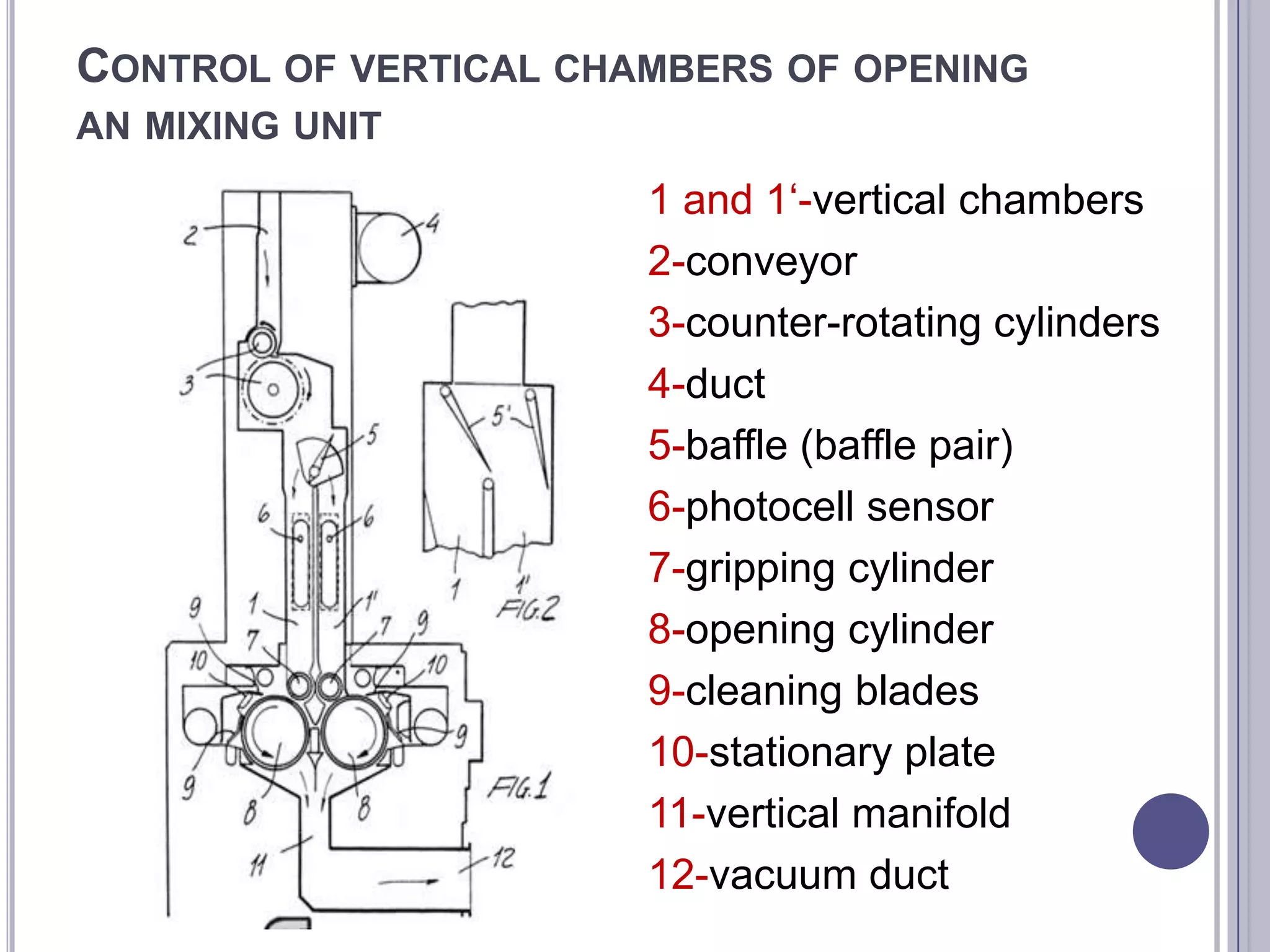

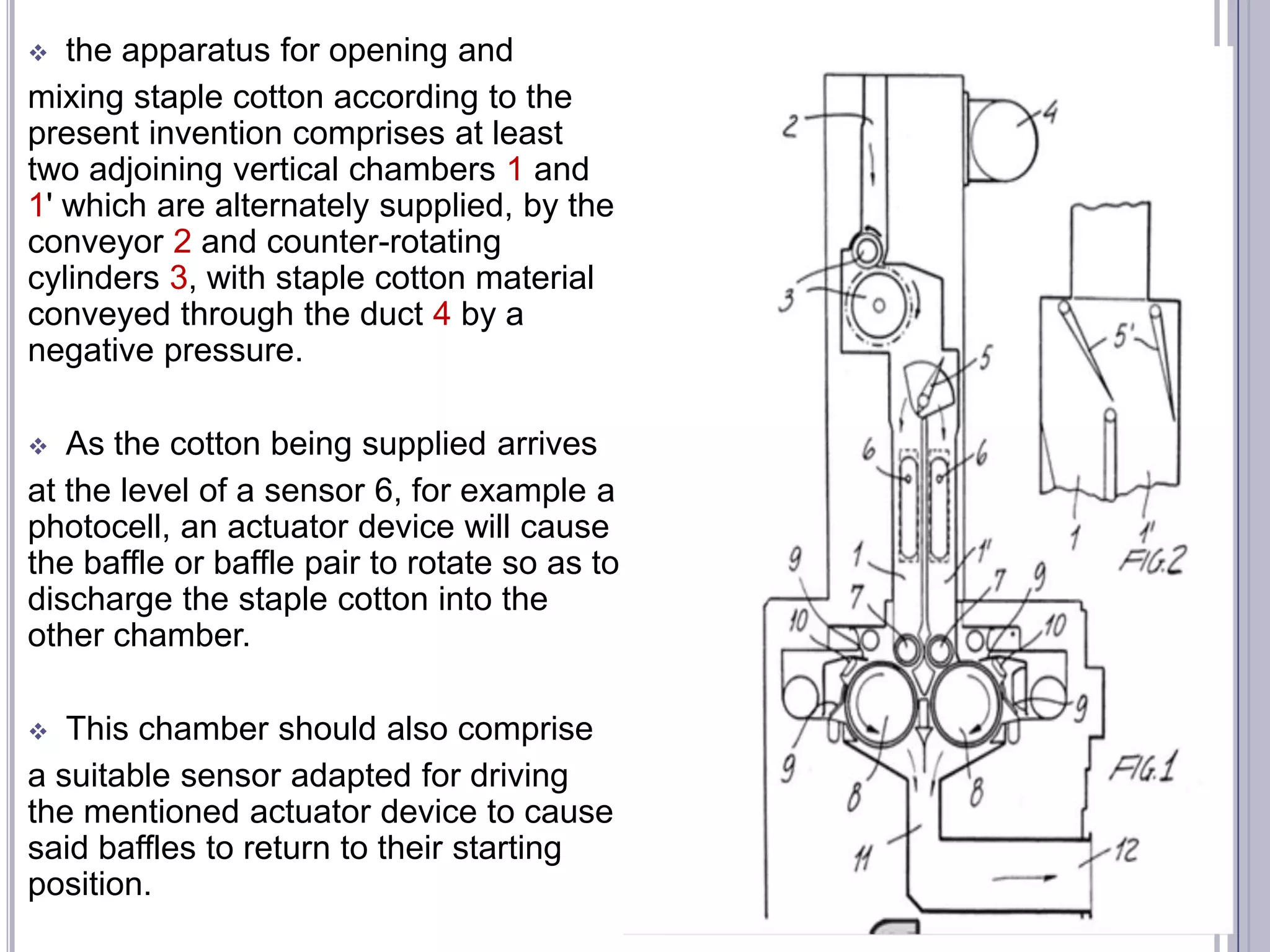

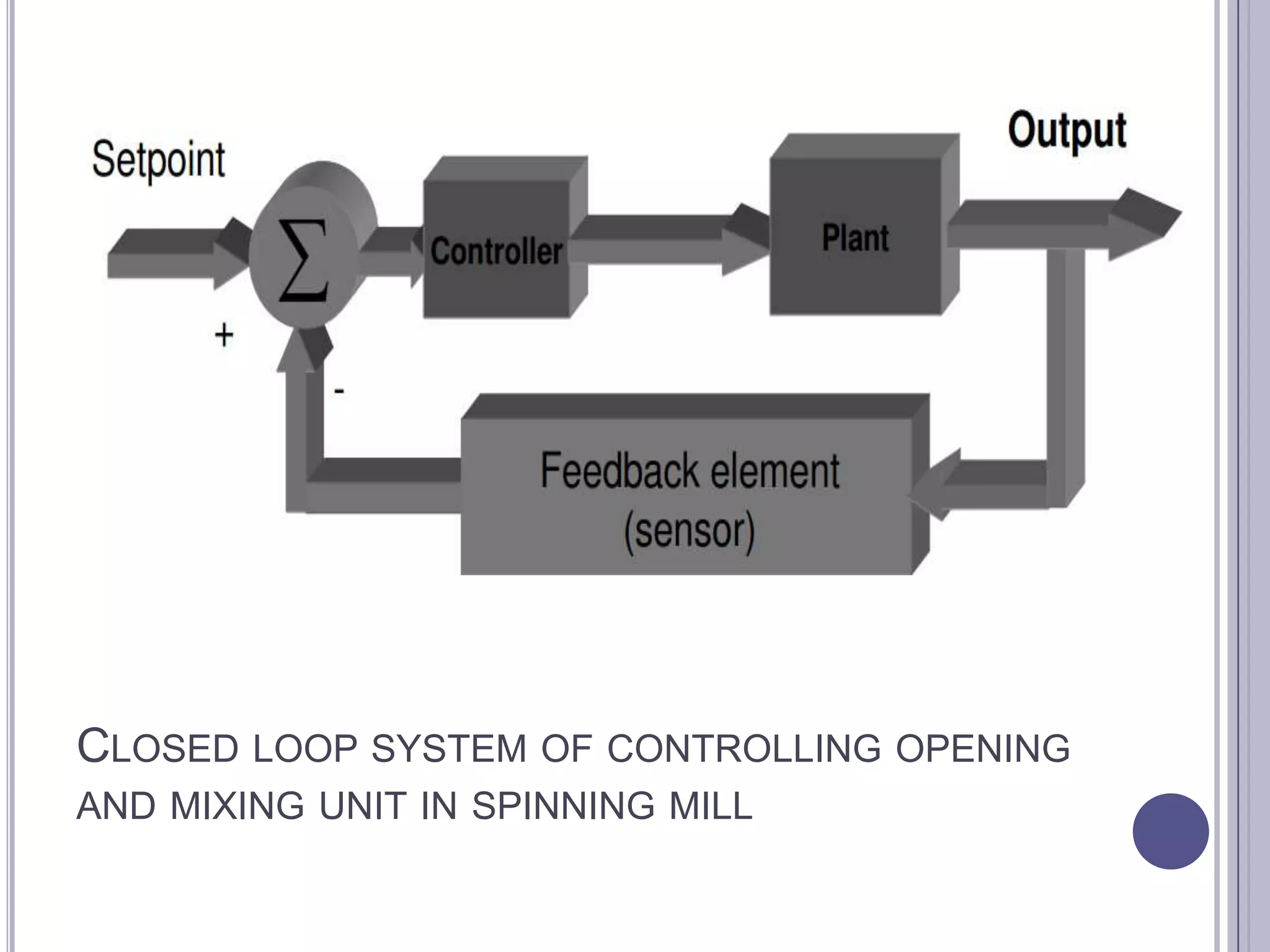

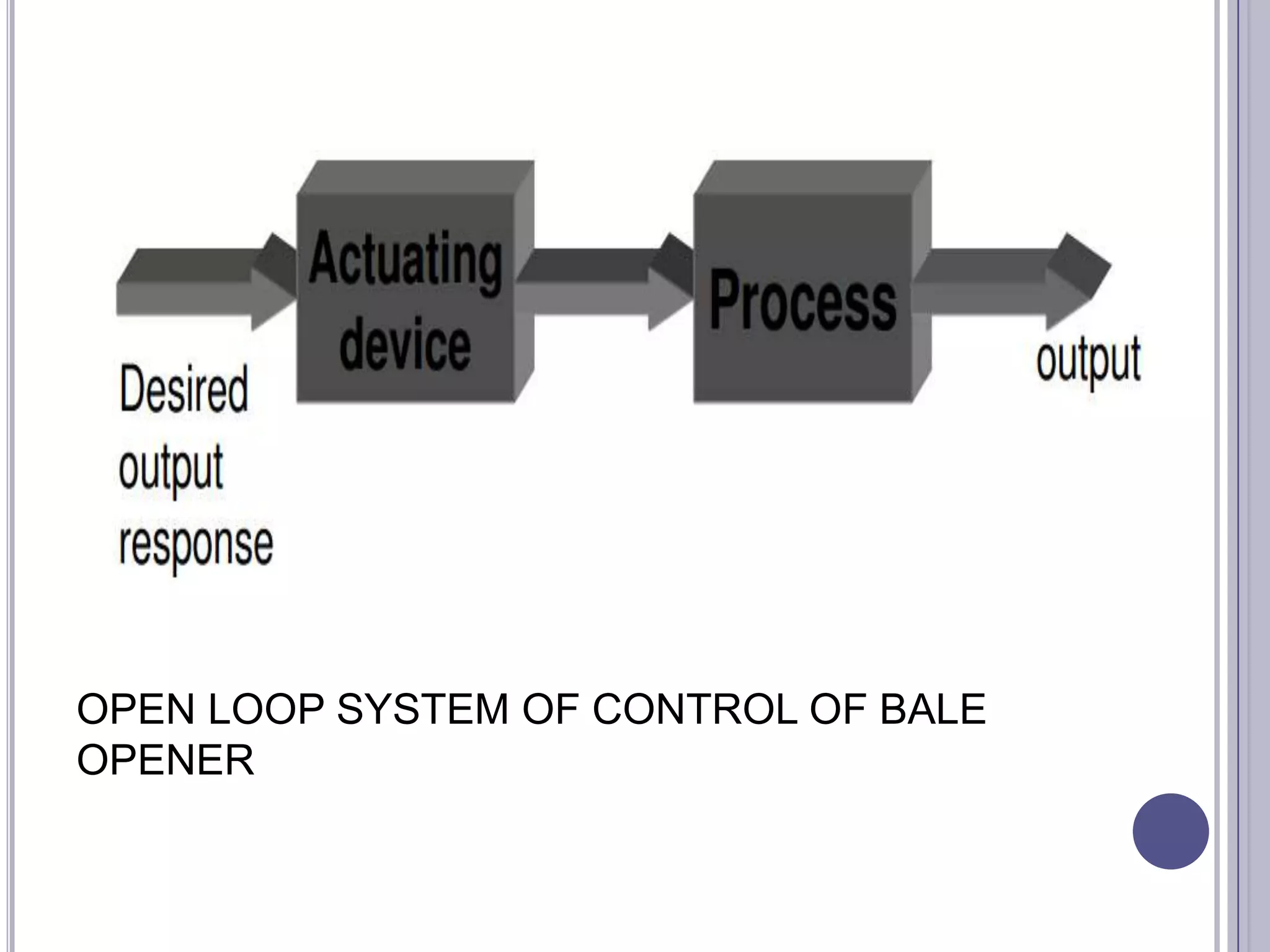

The document discusses control systems for blowroom machines from Rieter. It summarizes the functions and characteristics of various machines in the blowroom process, including the bale opener, pre-cleaner, homogeneous mixer, storage and feeding machine, and card. It also describes the control systems for machines like the bale opener, which uses sensors and motors connected to a control device to determine position and coordinate movement longitudinally and vertically.