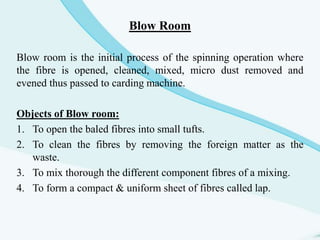

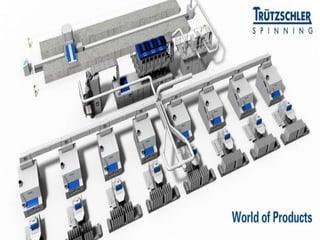

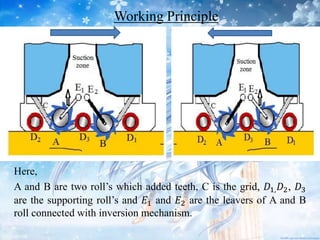

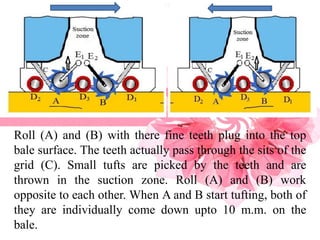

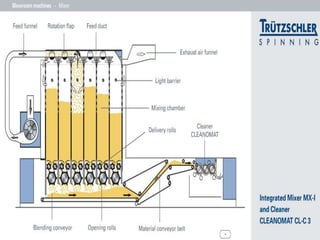

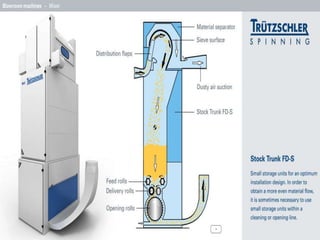

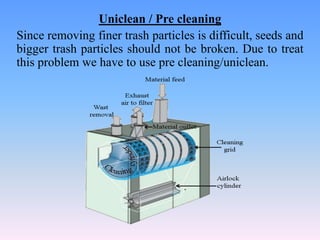

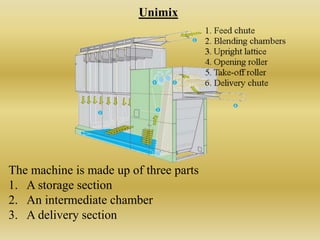

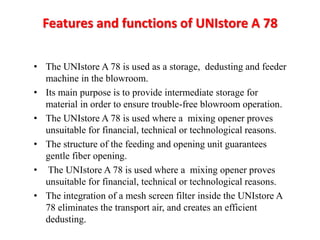

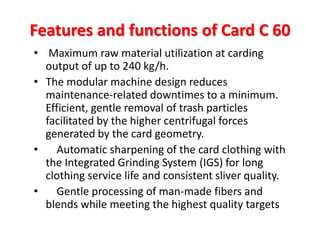

The document discusses the blow room process in the textile industry. It begins with an introduction of the presenters and topic. Then, it describes the basic functions of a blow room as opening, cleaning, mixing and forming laps of fiber. It provides details on various blow room technologies used like Blendomat, Axiflow cleaner, mixer, and dust removal systems. Finally, it outlines the components and functions of a modern blow room line and carding machine.