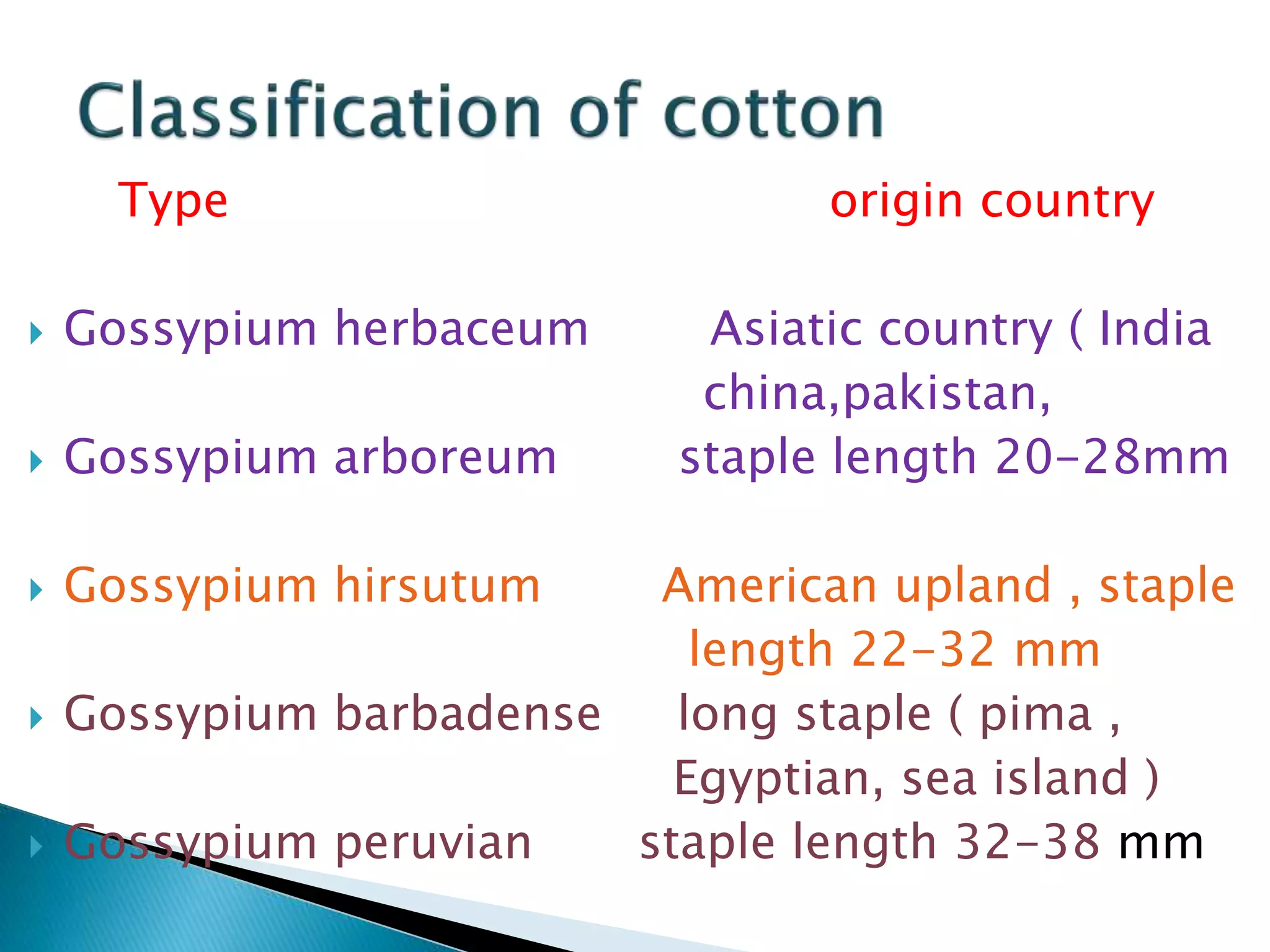

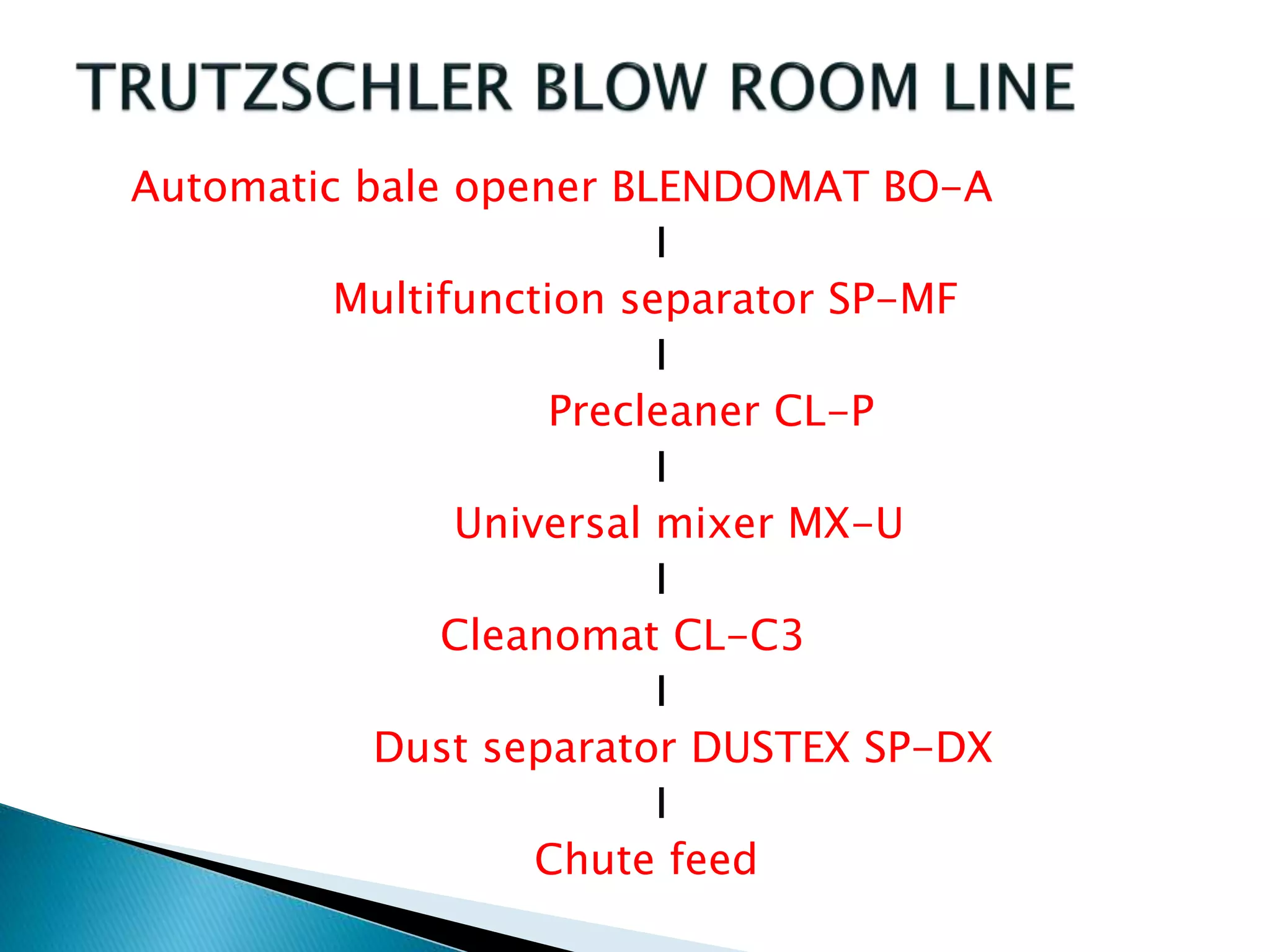

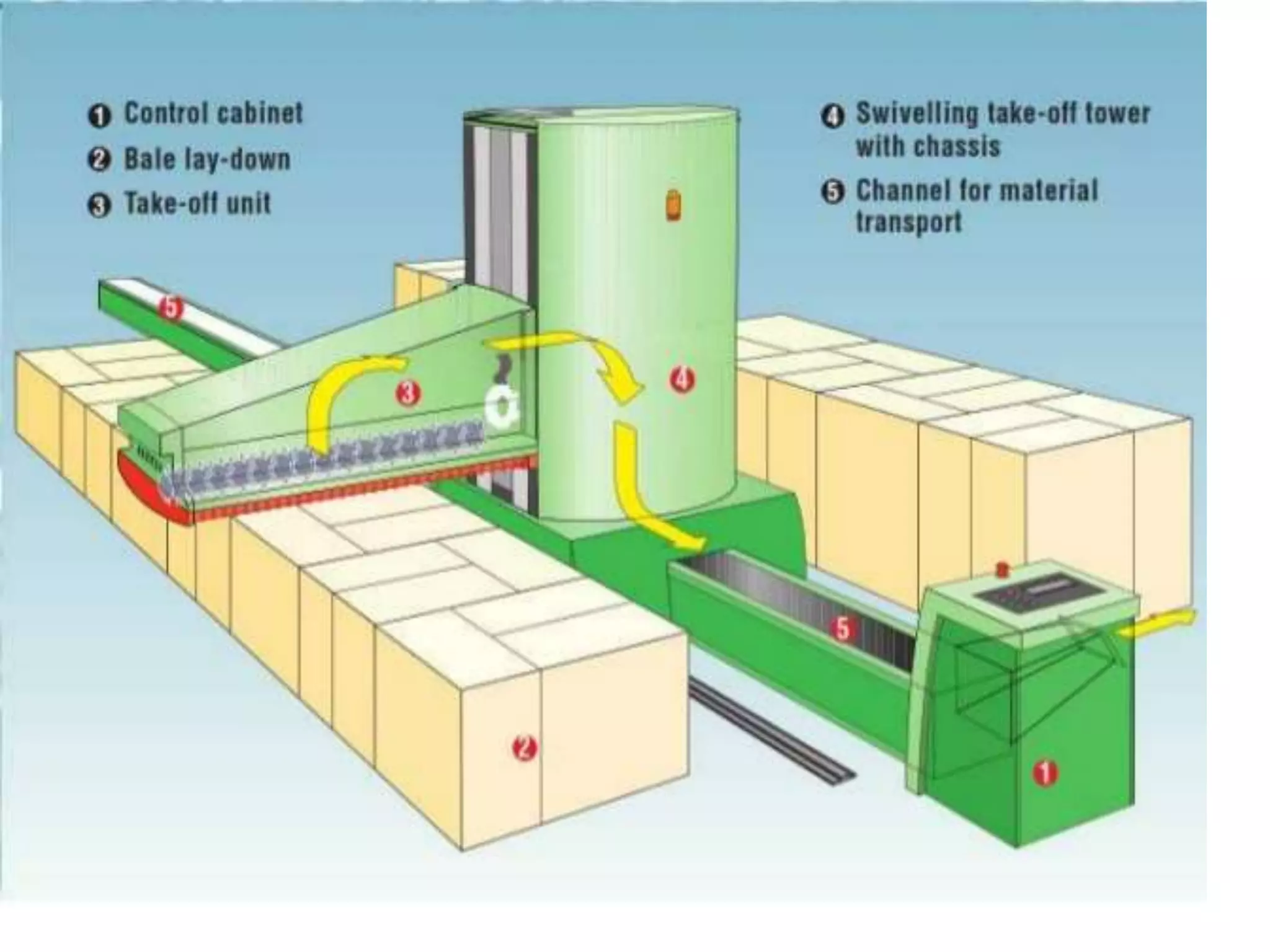

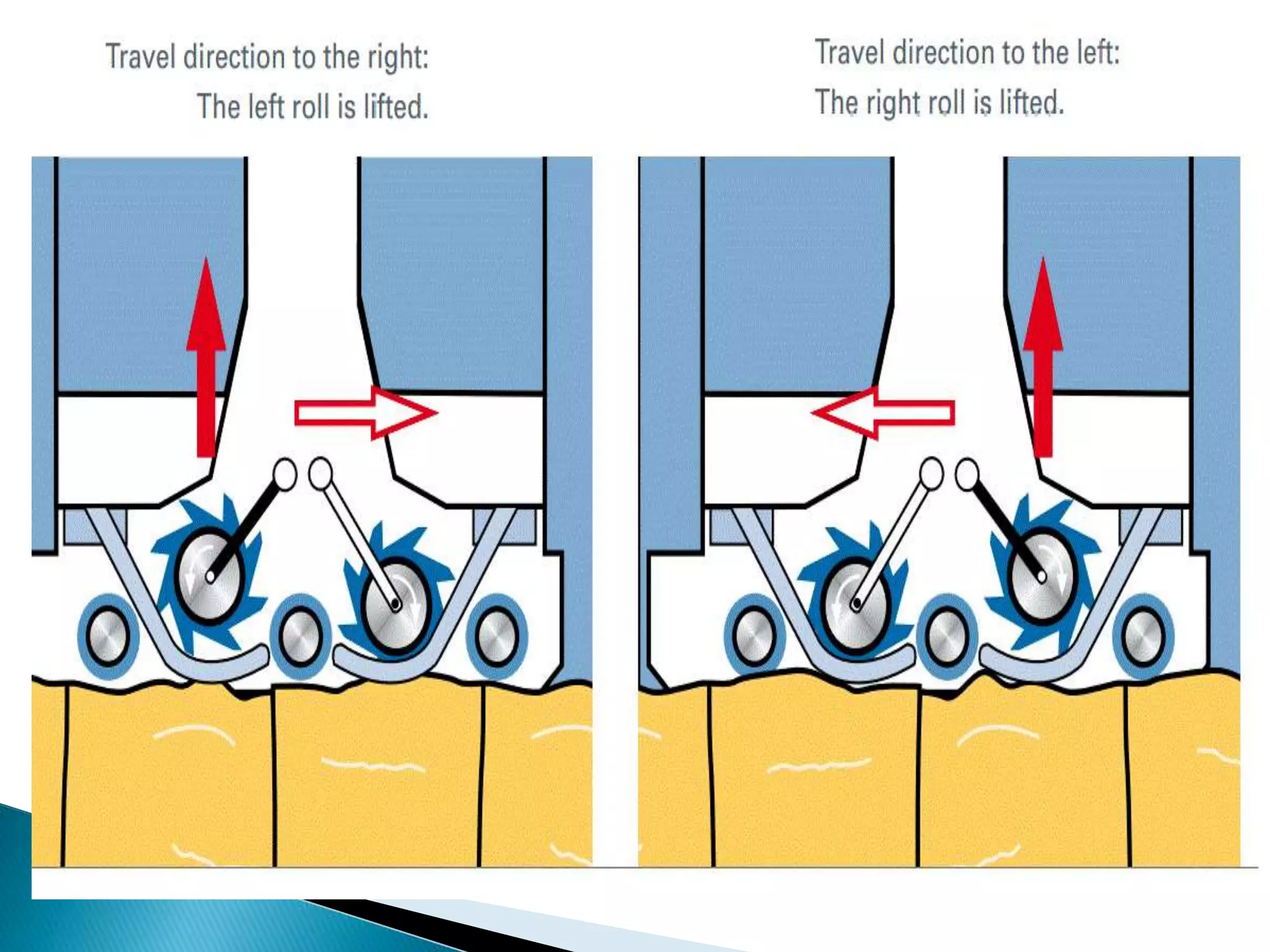

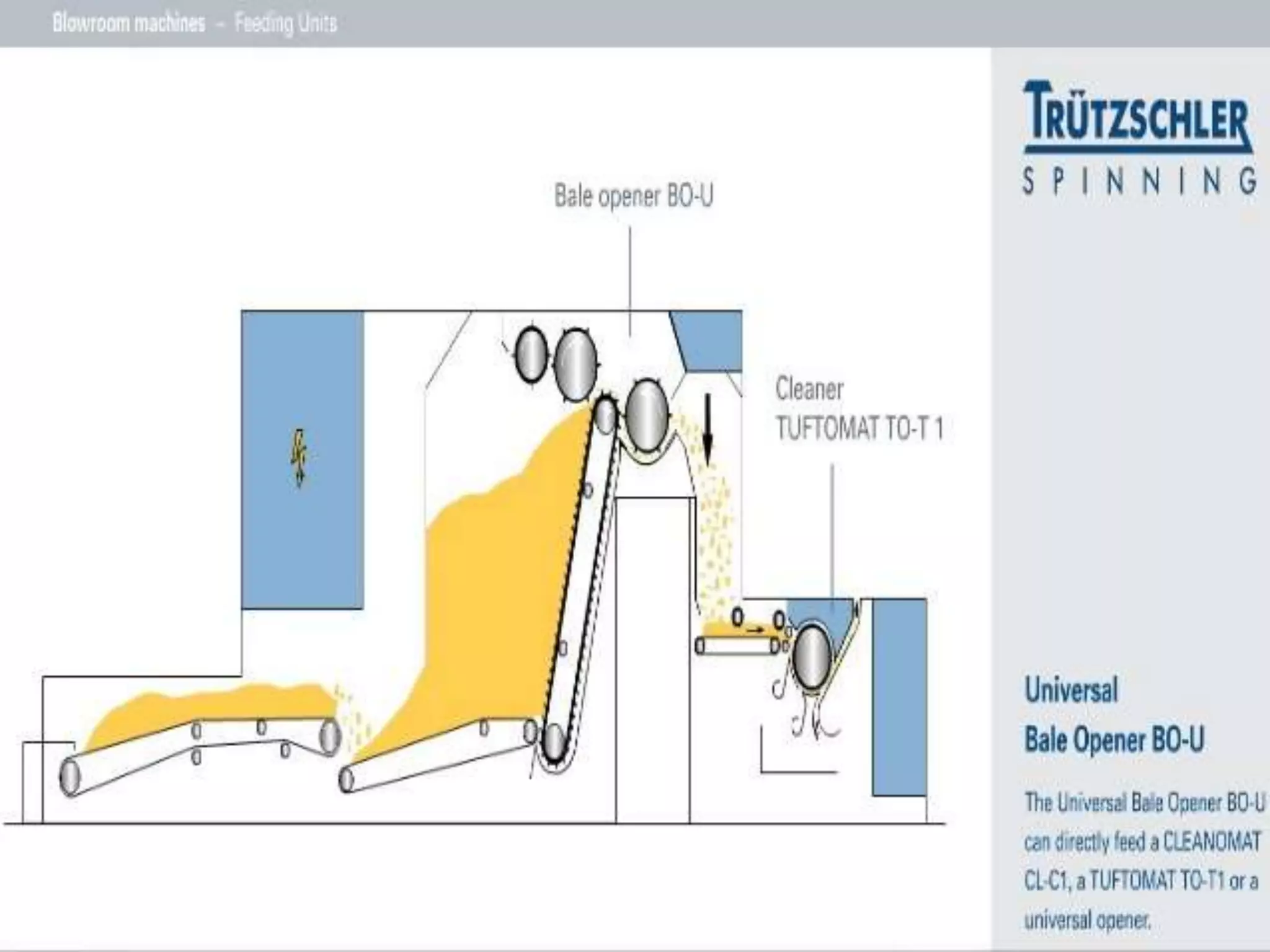

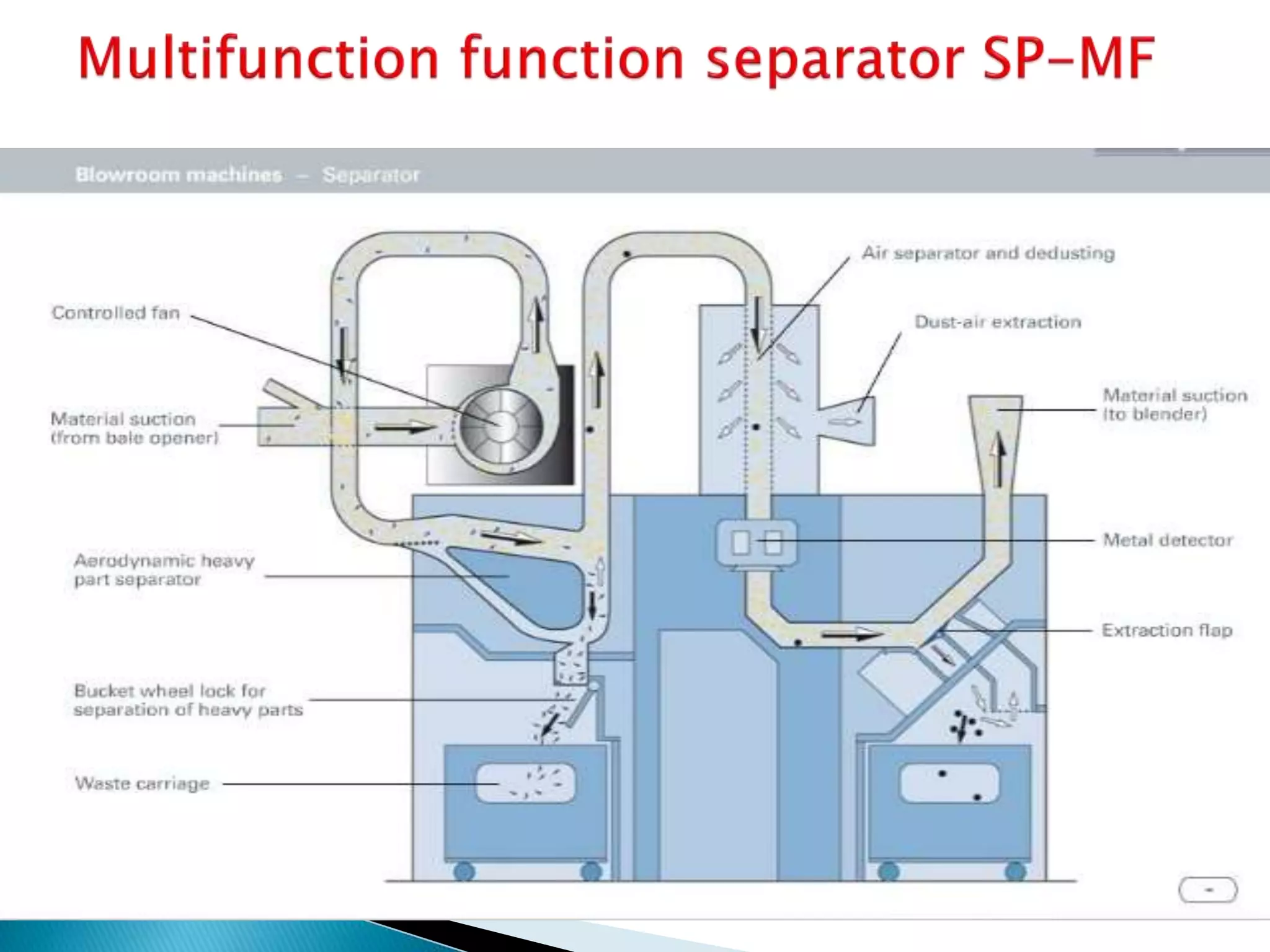

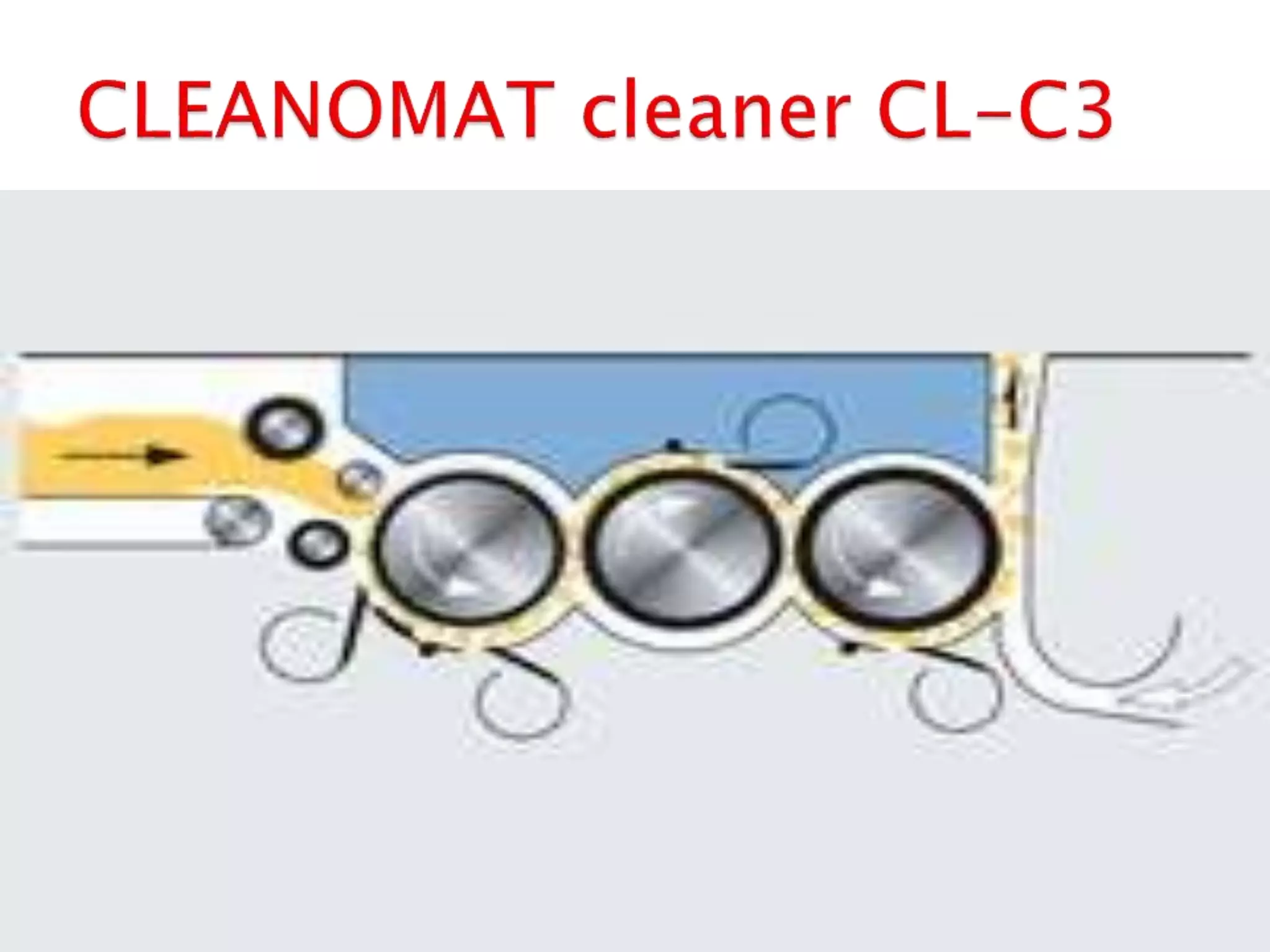

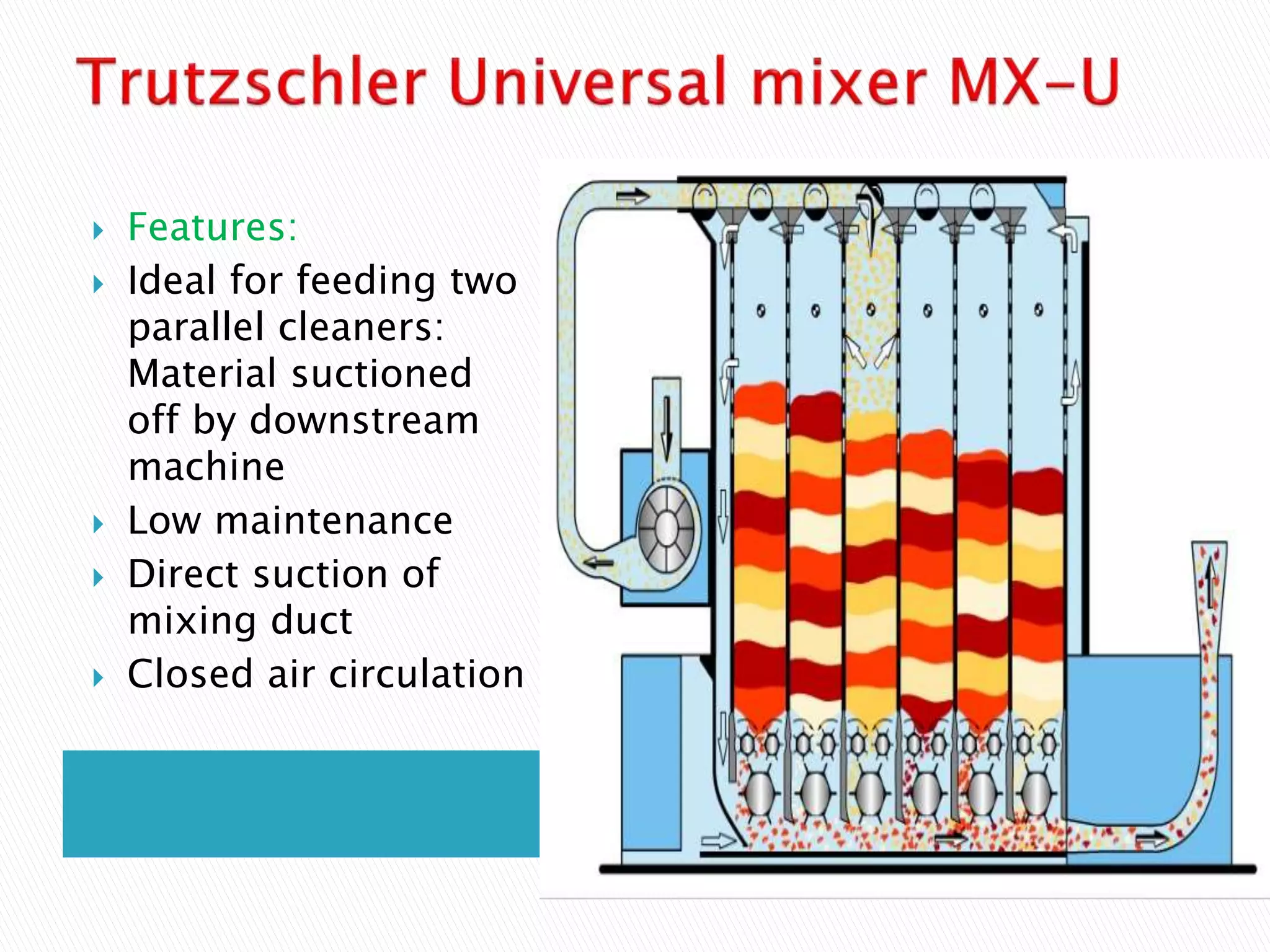

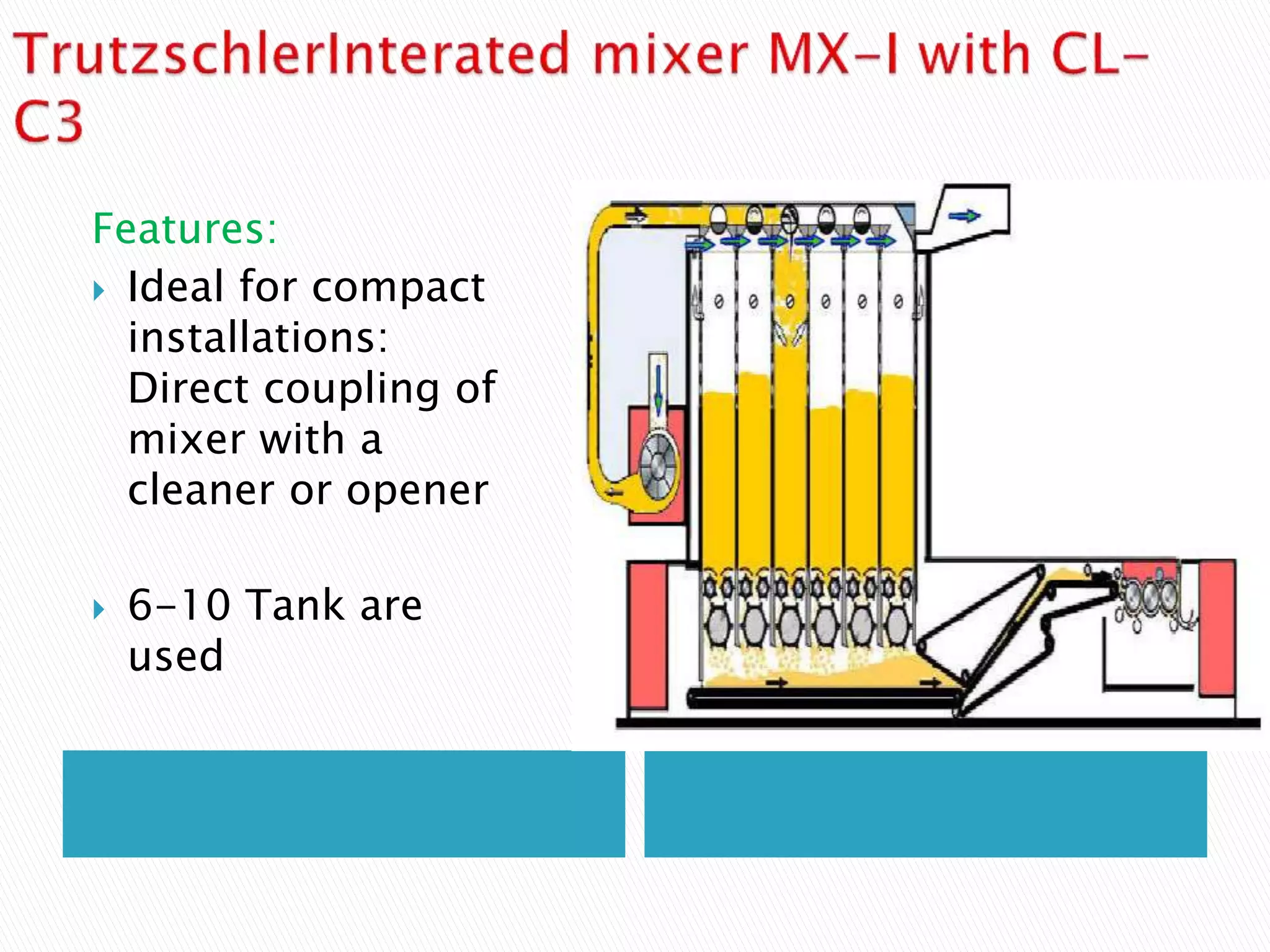

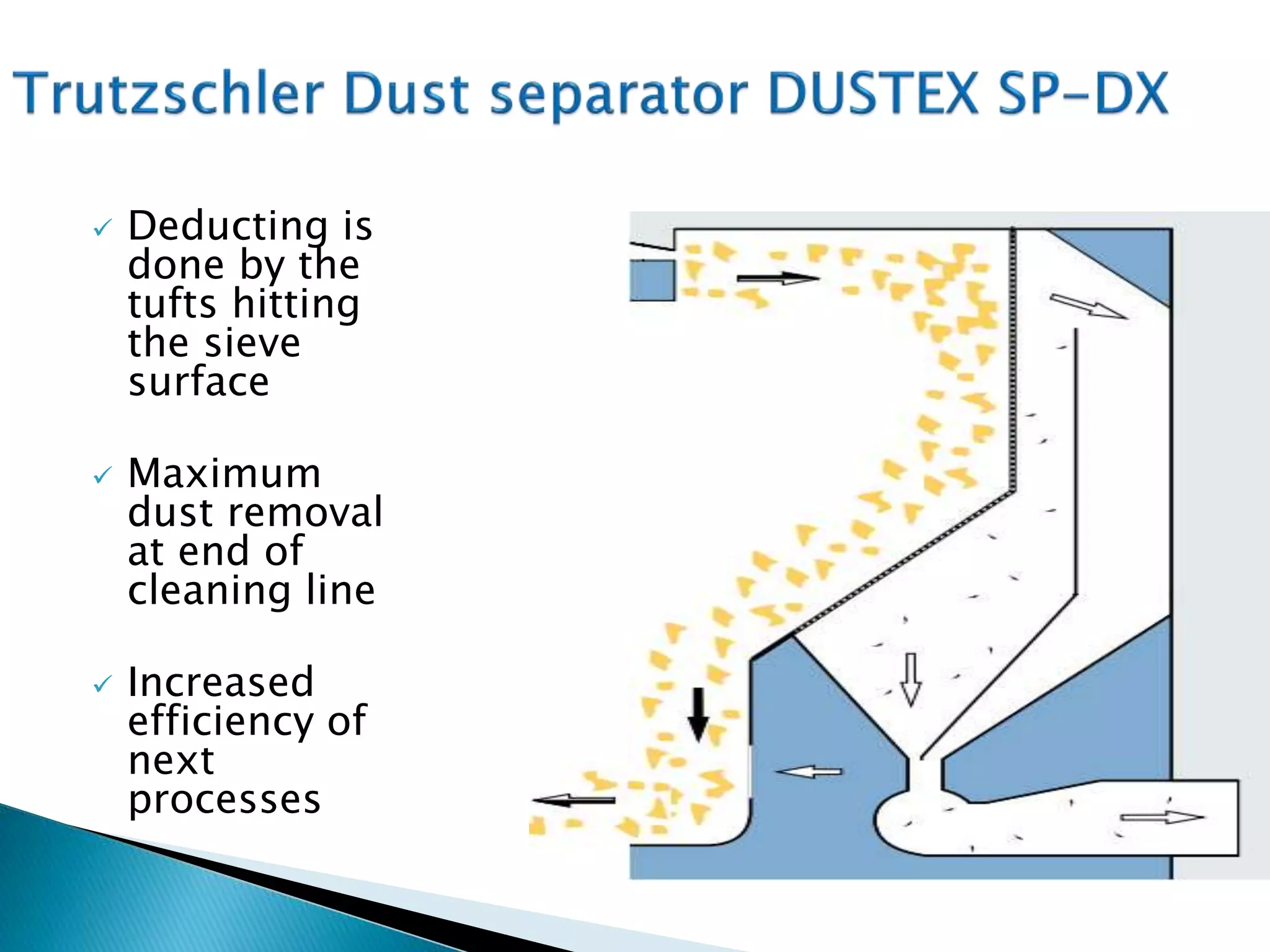

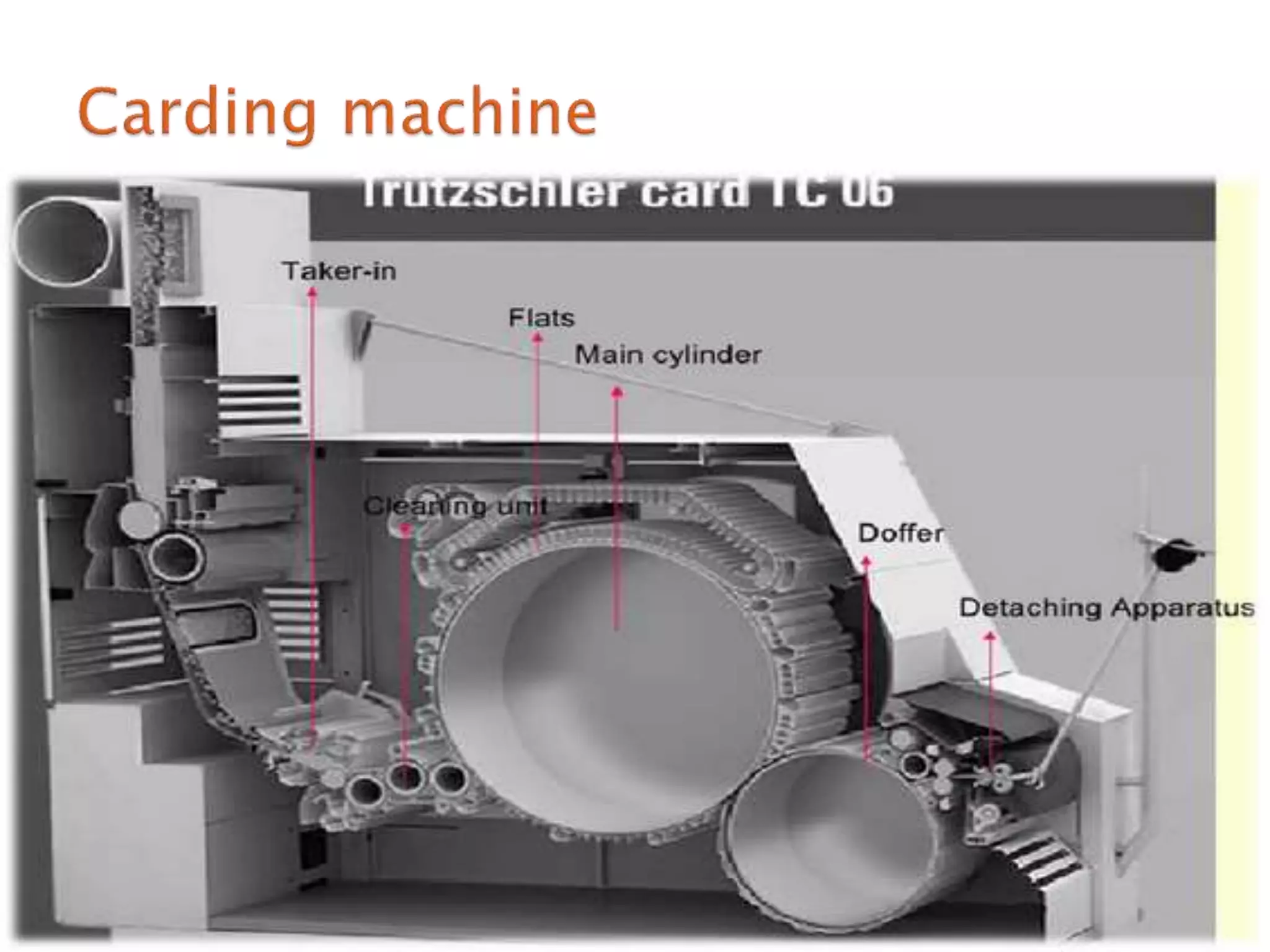

Fibers are the smallest elements that make up textile materials. Cotton is a natural fiber obtained from cotton plants, which belongs to the genus Gossypium. Cotton can fulfill 42% of global fiber demand and is produced in countries like the USA, China, India, Australia, and others. The blow room is the first processing section, which opens, cleans, blends, and mixes cotton fibers using machines like the bale opener, cleaner, and mixer to remove 40-70% of impurities. Carding further processes the fibers to individualize them and remove neps and short fibers in preparation for spinning. It drafts and orientates the fibers using components like the taker-in, cylinder, flats