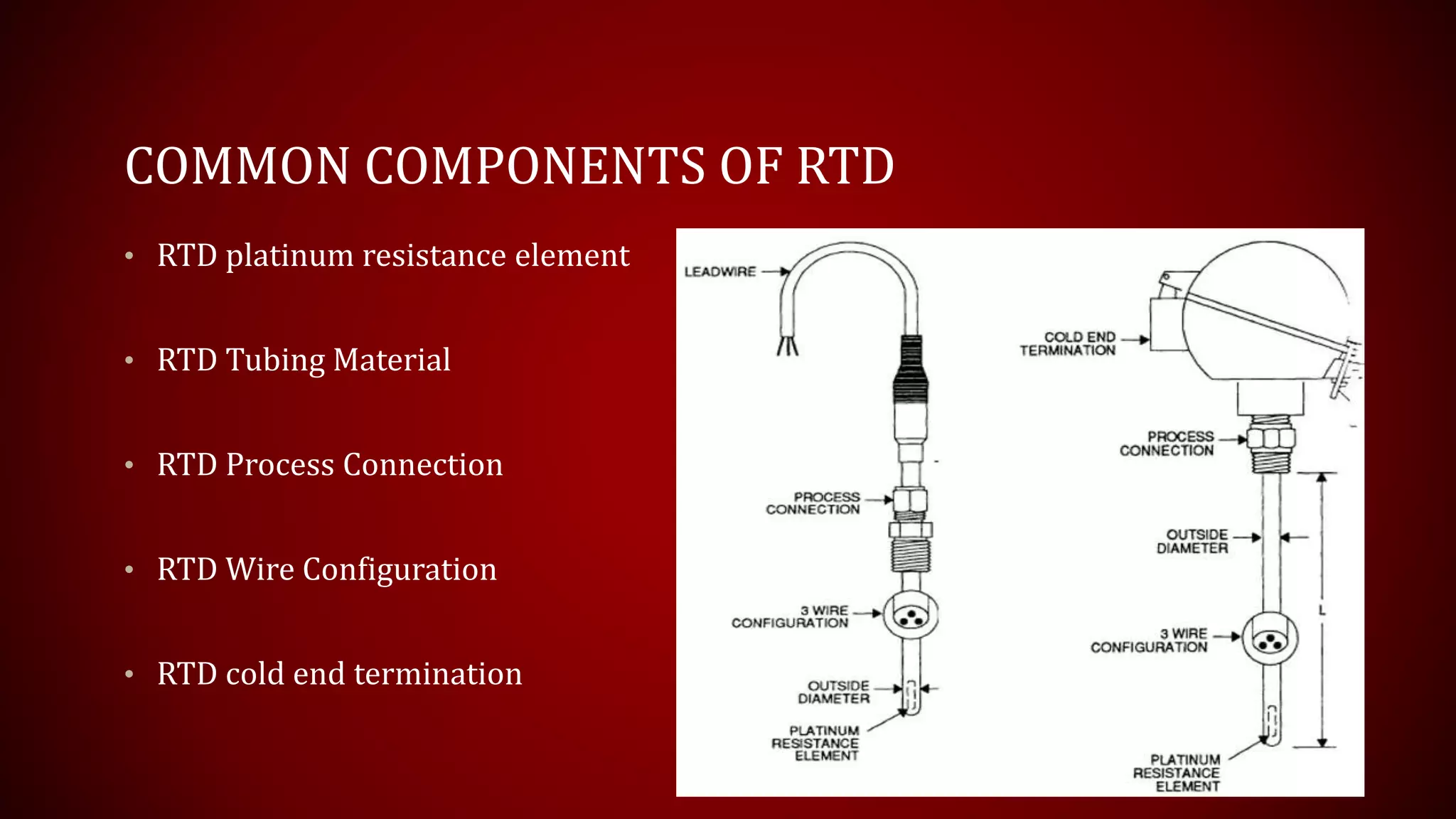

Resistance Temperature Detectors (RTDs) measure temperature through changes in metal resistance with temperature, commonly using platinum for its chemical inertness and stability. They come in various configurations and materials, with applications spanning automotive, electronics, food processing, and more. Thermistors, another type of temperature sensor, offer high sensitivity but exhibit non-linear resistance characteristics and are used in various devices for temperature control and measurement.