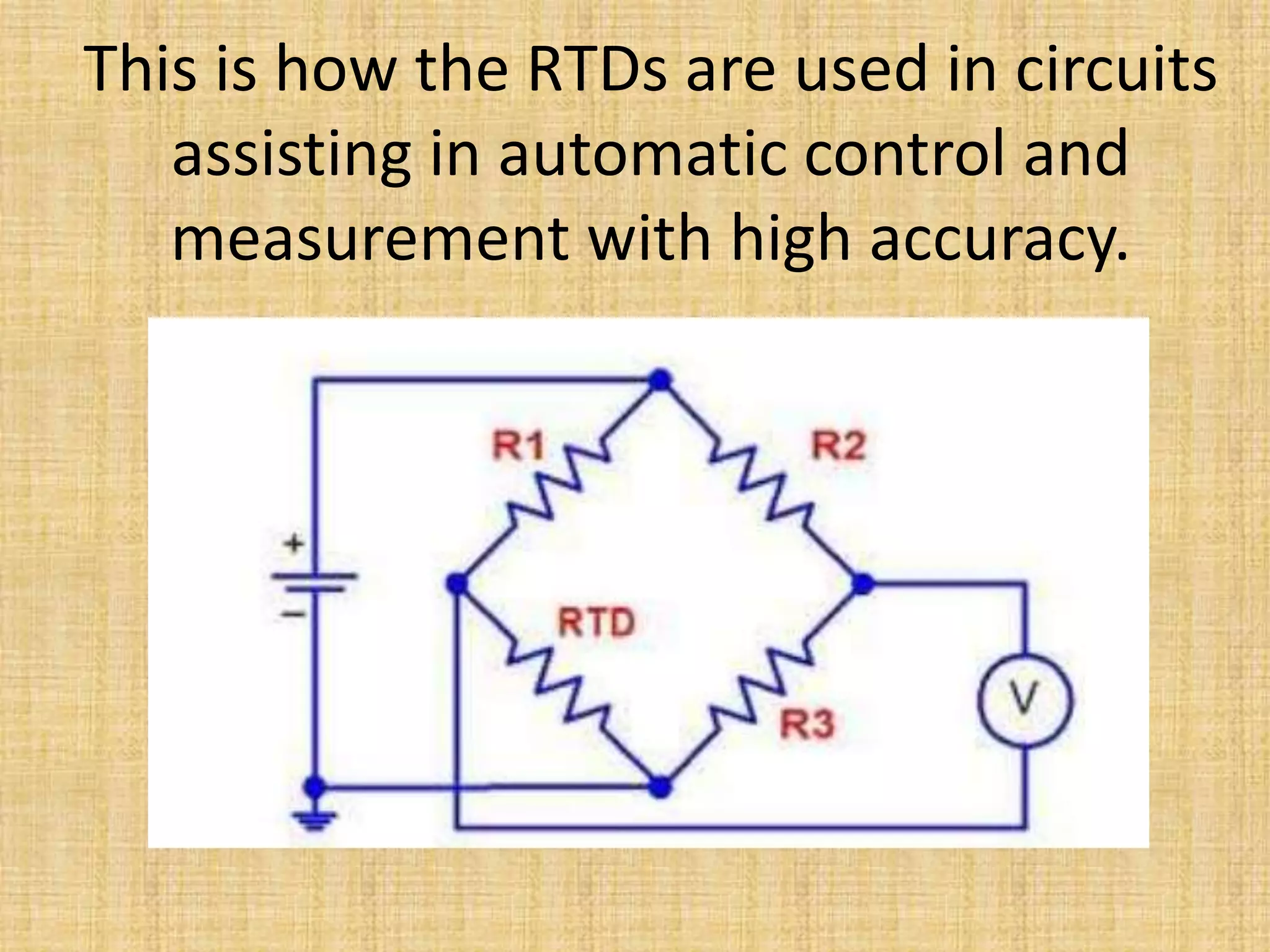

This document discusses resistance temperature detectors (RTDs). It explains that RTDs detect changes in temperature by measuring changes in the electrical resistance of a wire as temperature varies. Common wire materials used in RTDs include platinum, nickel, copper, and others. RTDs offer advantages like a wide temperature measurement range, good accuracy, and long-term stability. They are often used in temperature measurement and control applications like furnaces and laboratories.