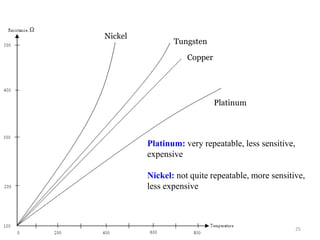

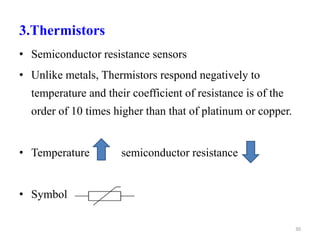

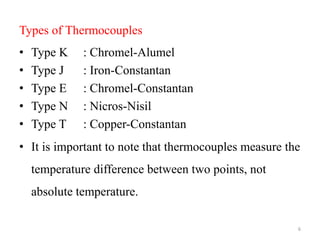

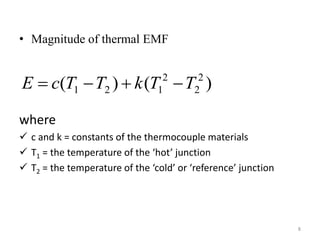

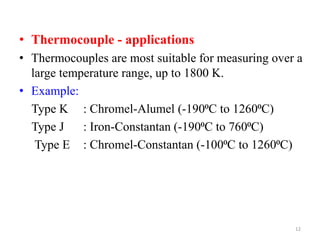

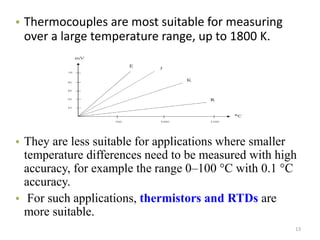

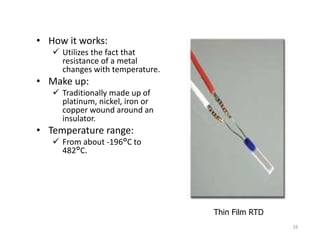

Thermocouples, resistance temperature detectors (RTDs), and thermistors are the three main types of temperature transducers. Thermocouples generate a voltage proportional to temperature difference by joining two dissimilar metals. RTDs measure temperature by relating the precise resistance change of materials like platinum to temperature. Thermistors are semiconductors whose high resistance changes significantly with temperature. Each transducer has advantages - thermocouples cover a wide range but with low accuracy, while RTDs and thermistors offer higher accuracy over smaller ranges. Applications include temperature monitoring and control in industries like food processing, automotive, solar energy, and healthcare.

![ RTD -Linear or Straight line equation

approximation

R(T)= approximation of resistance at temperature T

R(T0)= resistance at temperature T0

αo = fractional change in resistance per degree of temperature

at T0

ΔT= T - T0

2

1

]

1

)[

(

)

( T

T

T

T

T

R

T

R o

o

19](https://image.slidesharecdn.com/temperaturetransducers-231213134738-bbf82305/85/Temperature-Transducers-pptx-19-320.jpg)

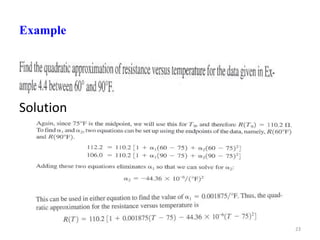

![RTD – quadratic approximation

• More accurate representation of R-T curve over some span

of temperatures.

R(T) = quadratic approximation of resistance at temperature T

R(T0)= resistance at temperature T0

α1 = linear fractional change in resistance with temperature

α2 = quadratic fractional change in resistance with temperature

ΔT = T - T0

2

1

2

2

1 ]

)

(

1

)[

(

)

( T

T

T

T

T

T

R

T

R o

22](https://image.slidesharecdn.com/temperaturetransducers-231213134738-bbf82305/85/Temperature-Transducers-pptx-22-320.jpg)