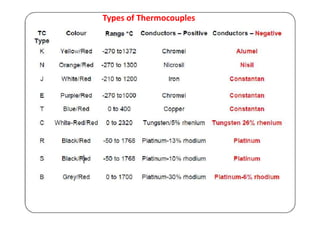

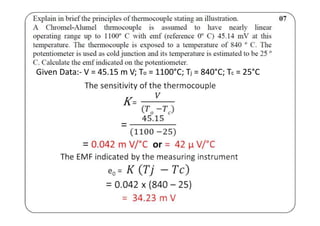

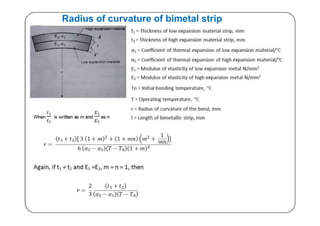

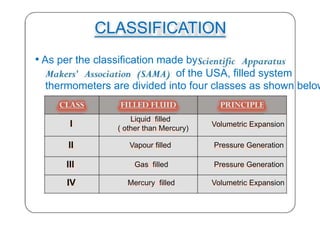

This document provides an overview of different temperature measurement devices and concepts. It discusses liquid-in-glass thermometers, bimetallic thermometers, pressure/filled system thermometers including classifications based on liquid, vapor, gas and mercury filling. It also covers electrical temperature measurement using resistance temperature detectors (RTDs), thermistors, and thermocouples. Sources of error and advantages/disadvantages are described for each type of temperature measuring device.

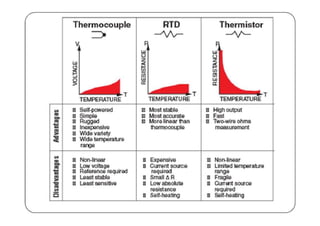

![Electrical Temperature Measuring Instruments

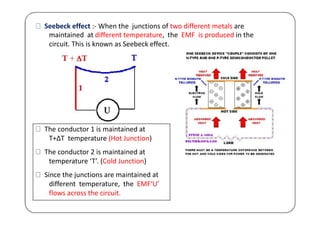

Change in electrical properties of sensor for estimating temperature

1. Resistance Temperature Detectors (RTD)

2. Thermistors

3. Thermocouples and Thermopiles

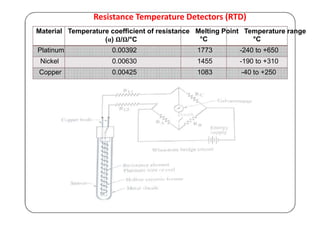

Resistance Temperature Detectors (RTD)

Use change in resistance of suitable metals to indicate temperature.

Commonly used metals are platinum, nickel, copper which show a

positive change in resistance with increase in temperature.

The variation in resistance R at temperature can be written as

RT = R0 [ 1 + α T + β T2]

RT = Resistance at temperature T °C

R0 = Resistance at 0° C

or RT = R0 [ 1 + α T]

α and β are constant whose value depends on the RTD materials.](https://image.slidesharecdn.com/temperaturemeasurement-170509112656/85/Temperature-measurement-37-320.jpg)

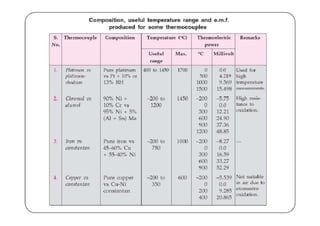

![Comparison of RTD and Thermistors

# Characteristic RTD Thermistors

1 Change in resistance Positive, Resistance increase Negative, Resistance decreases

with temperature with increase in temperature with increase in temperature

2 Temperature resistance Approximately linear

relationship RT = R0 [ 1 + α T]

3 Operating range -160°C to 600°C -100°C to 300°C

4 Composition Platinum, Copper, Nickel Metallic oxides like Manganese,

Nickel, Copper, Iron, Titanium,

Uranium

5 Sensitivity Lower Higher

6 Cost High Low](https://image.slidesharecdn.com/temperaturemeasurement-170509112656/85/Temperature-measurement-44-320.jpg)

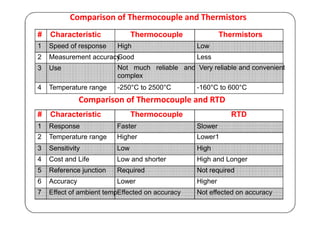

![Components of Thermocouples

type JIS + -

B -

70 % Platinum 94 % Platinum

30 % Rhodium 6 % Rhodium

R PR

S -

K CA

E CRC

87 % Platinum

13 % Rhodium

90 % Platinum

10 % Rhodium

Chromel

[90 % Ni · 10 % Cr]

Chromel

[90 % Ni · 10 % Cr]

100 % Platinum

100 % Platinum

Alumel

[95 % Ni· 2 % Mn · 2 % Al]

Constantan

[55 % Cu · 45 % Ni]

J IC 99.5 % Iron

T CC 1 0 0% Copper

Constantan

[55 % Cu · 45 % Ni]

Constantan

[55 % Cu · 45 % Ni]

N -

Nicrosil

[84 % Ni ·14.2 % Cr ·1.45 % Si]

Nisil

[95 % Ni · 4.4 % Si · 0.15 % Mg]](https://image.slidesharecdn.com/temperaturemeasurement-170509112656/85/Temperature-measurement-55-320.jpg)