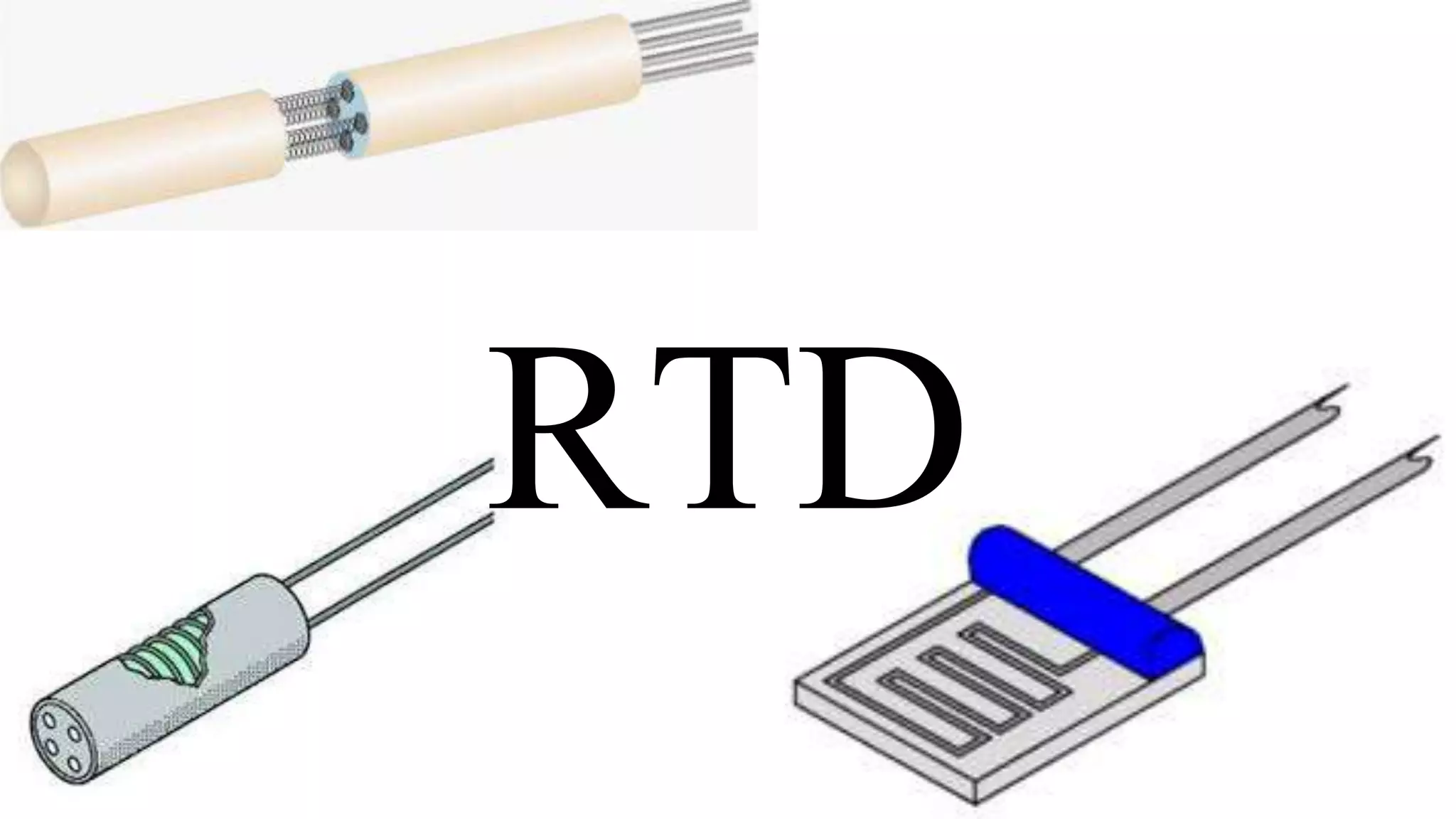

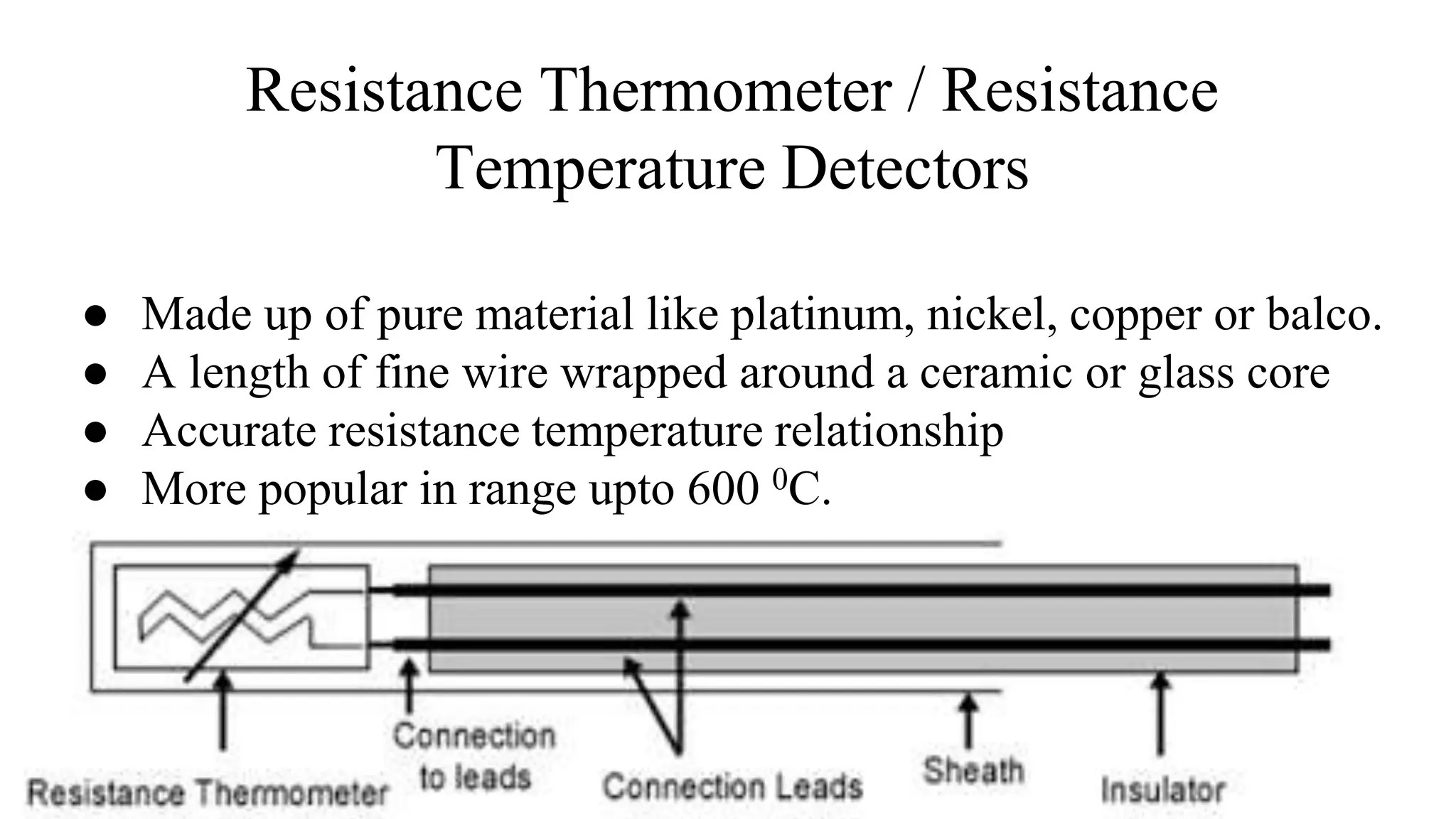

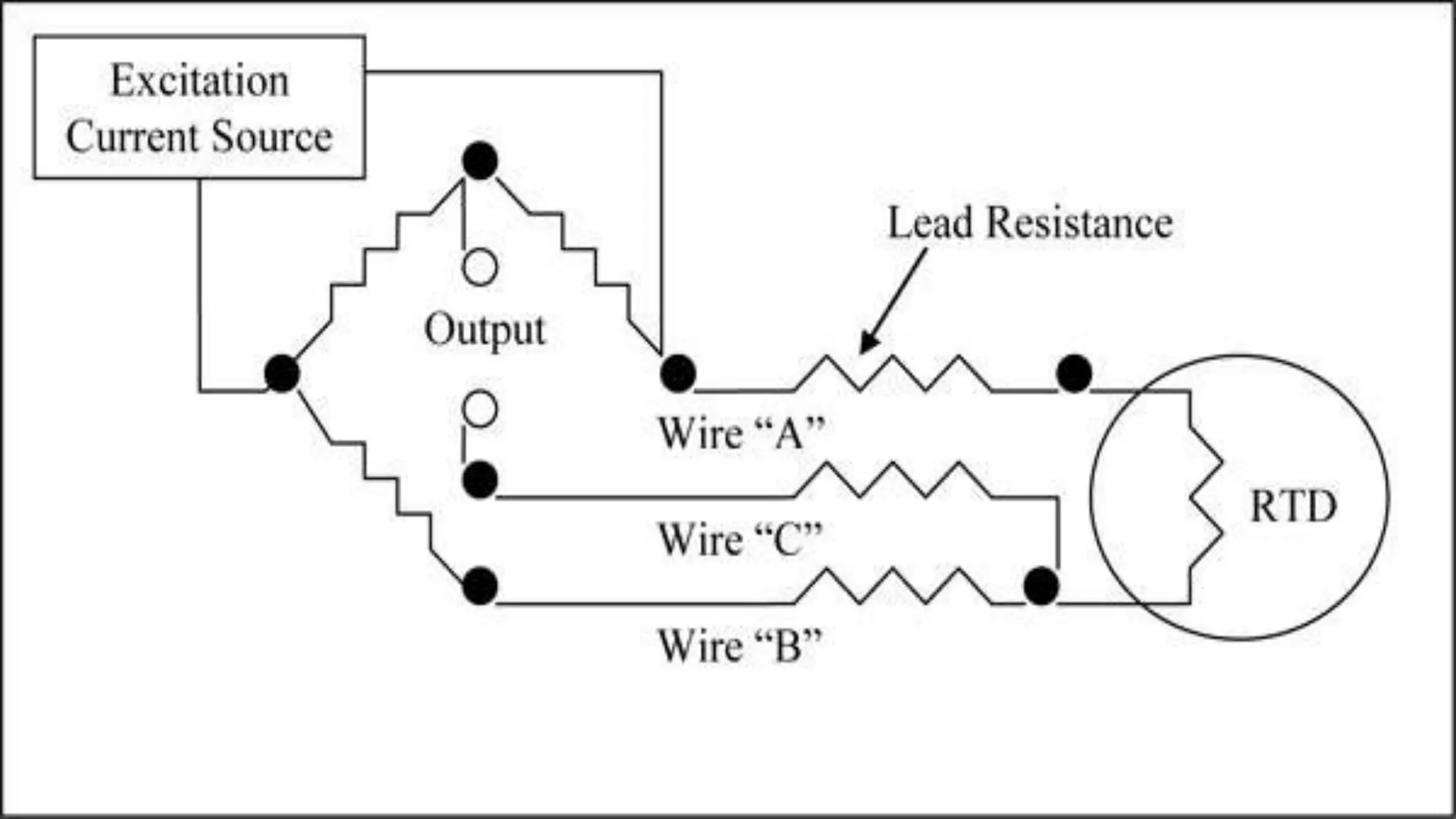

RTDs (Resistance Temperature Detectors) measure temperature through changes in metal resistance, using materials like platinum or nickel, and are classified by their resistance at 0°C. There are various designs including thin film, wire wound, and partially supported elements, with common industrial configurations being 2, 3, or 4 wire types for improved accuracy. Calibration and accuracy standards are defined by classes (A, B, etc.), mainly outlined in IEC 751, with tolerance levels varying based on the class designation.