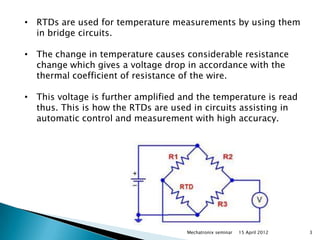

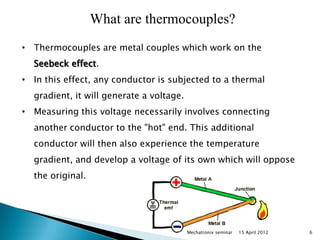

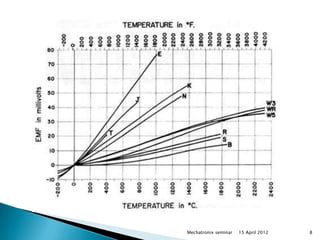

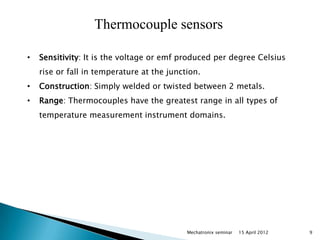

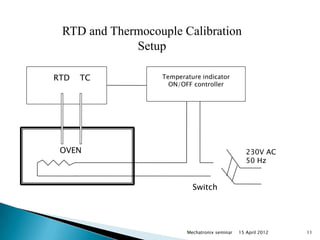

RTDs measure temperature by detecting changes in electrical resistance of a wire as temperature varies. There are two types based on whether resistance increases or decreases with temperature. RTDs are used in bridge circuits where changes in resistance produce voltage changes proportional to temperature. Thermocouples use the Seebeck effect where different metals produce voltage when joined and subjected to a temperature gradient. Common types include J, K, B, S, T, and R which vary in sensitivity and measurable temperature range. Both RTDs and thermocouples require signal conditioning due to their small voltage outputs and are calibrated using a temperature indicator, controller, and oven.