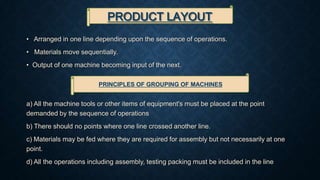

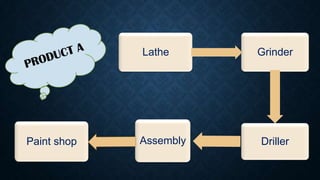

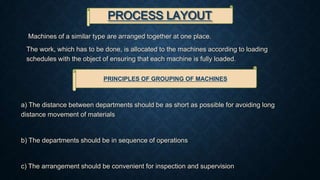

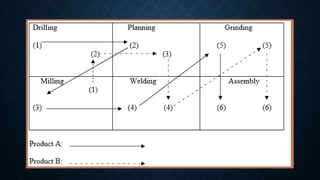

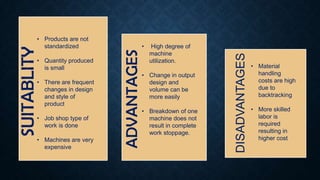

The document discusses two types of layouts for manufacturing processes: product layout and process layout. Product layout arranges machines in a straight line based on the sequence of operations, allowing materials to move sequentially from one machine to the next. Process layout groups similar machines together to maximize machine utilization. The key advantages of product layout are smooth operations and low material handling costs, while the disadvantages include lack of flexibility and stoppage if a machine breaks down. Process layout is more suitable for non-standardized products in smaller quantities with design changes, and has higher material handling costs but avoids complete stoppage if a machine breaks down.