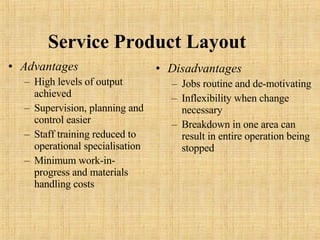

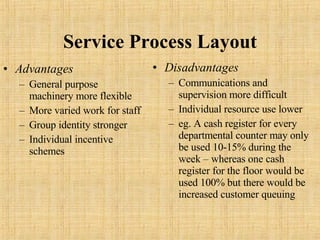

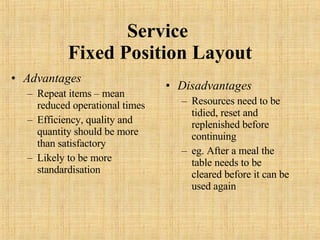

The document discusses different types of facility layouts and their advantages and disadvantages. It describes product layouts, which are best for moving large quantities of items or people smoothly, and process layouts, which group similar processes together and allow for more flexibility but can be more difficult to supervise. It also covers fixed position layouts, used when products must be created on-site, and discusses requirements like staff training and potential problems with layouts like bottlenecks, supervision issues, and demotivating spaces.