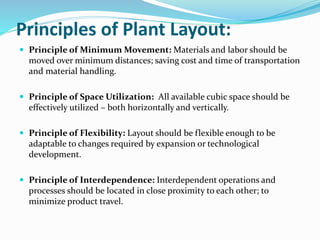

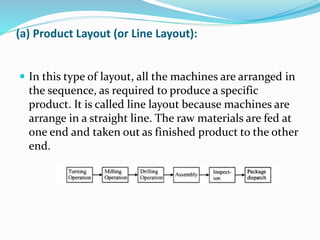

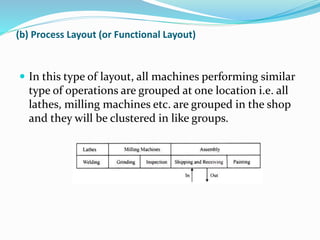

Plant layout refers to the arrangement of machines, materials, personnel and supporting services within a manufacturing facility. The objectives of plant layout include streamlining material flow, minimizing handling, maintaining process balance, and maximizing space and employee efficiency. There are four main types of layouts: product layout arranges machines in linear sequence to produce a single product; process layout groups similar machines together; combination layout blends aspects of product and process; and fixed position layout keeps large products stationary while bringing materials and machines to them. The document discusses the characteristics and suitability of each layout type.