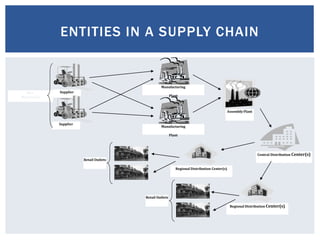

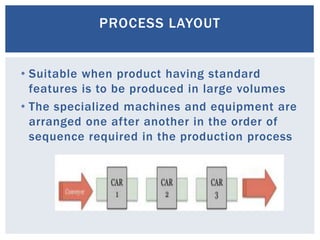

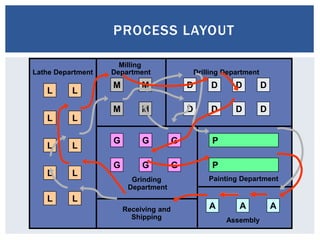

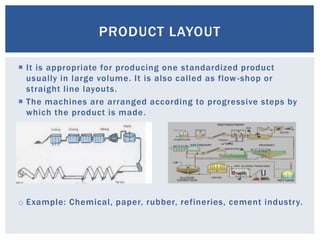

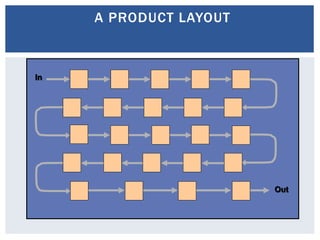

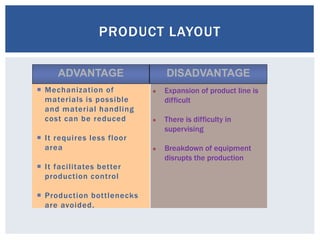

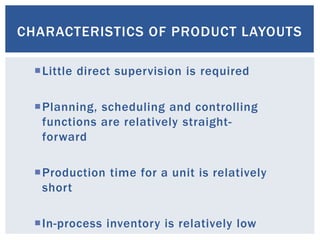

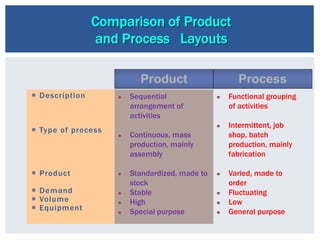

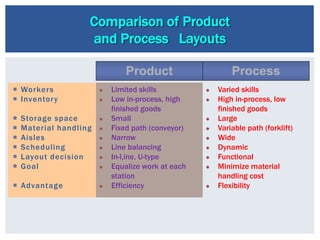

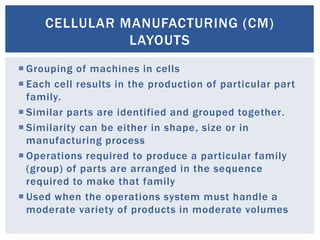

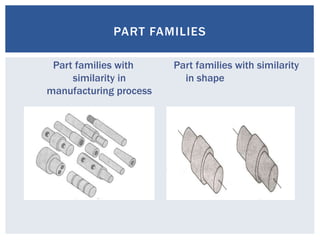

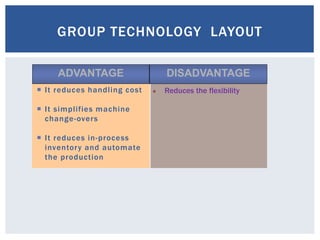

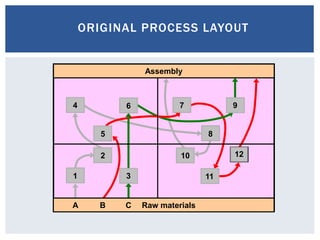

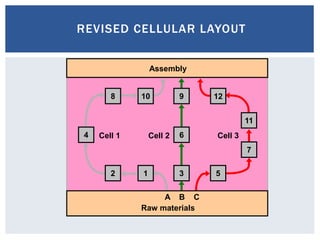

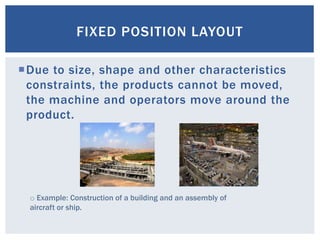

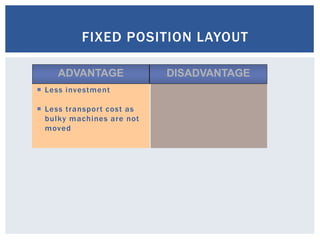

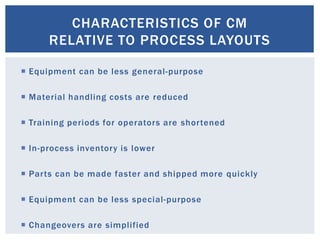

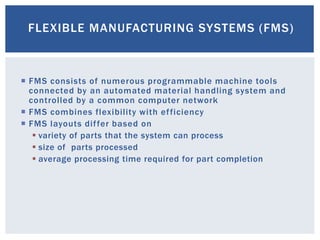

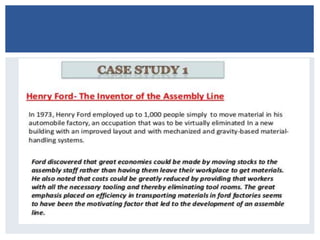

The document discusses various types of facility layouts used in manufacturing and non-manufacturing settings. It describes McDonald's use of process layouts across its global supply chain, with centralized distribution centers and strict logistical controls to ensure consistent food quality and on-time deliveries. The document also covers other layout types like product layouts, group technology layouts, and fixed position layouts, comparing their characteristics and suitability for different production environments.