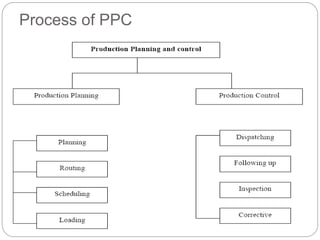

The document discusses production planning and control (PPC) in small industries. PPC involves planning and organizing the manufacturing process to efficiently utilize capacity, control inventory, reduce production time, ensure quality, and improve response time and quality. The process of PPC includes planning production needs, routing operations, scheduling work, loading assignments, production control, dispatching work orders, follow up on progress, inspection, and corrective measures. The overall goal of PPC is the optimal organization of materials, labor, machines and activities to achieve desired manufacturing outputs.