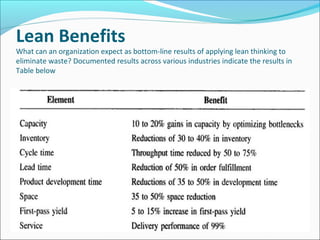

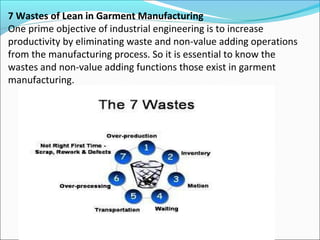

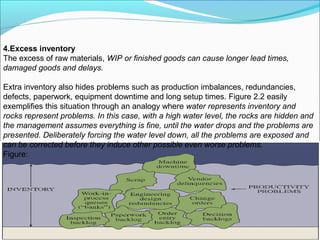

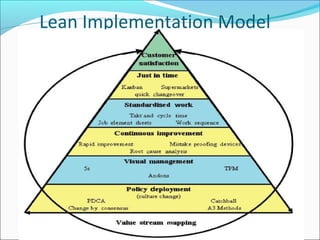

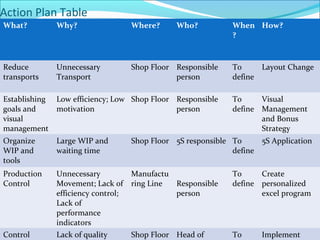

This presentation discusses applying lean manufacturing tools in the garment production industry. It begins with an introduction to lean manufacturing and its principles of value, value stream, flow, pull and perfection. Common wastes in garment manufacturing are identified as overproduction, waiting time, unnecessary transport, excess inventory, incorrect processing, unnecessary movement, and defects. Eight preferred lean tools for the garment industry are highlighted: 5S, visual displays, standardization, quick changeovers, error proofing, Kanban, cellular manufacturing, and Kaizen. Implementation of some lean tools in a Portuguese garment firm showed encouraging results like a 14% increase in productivity and 60% increase in profits within two months.