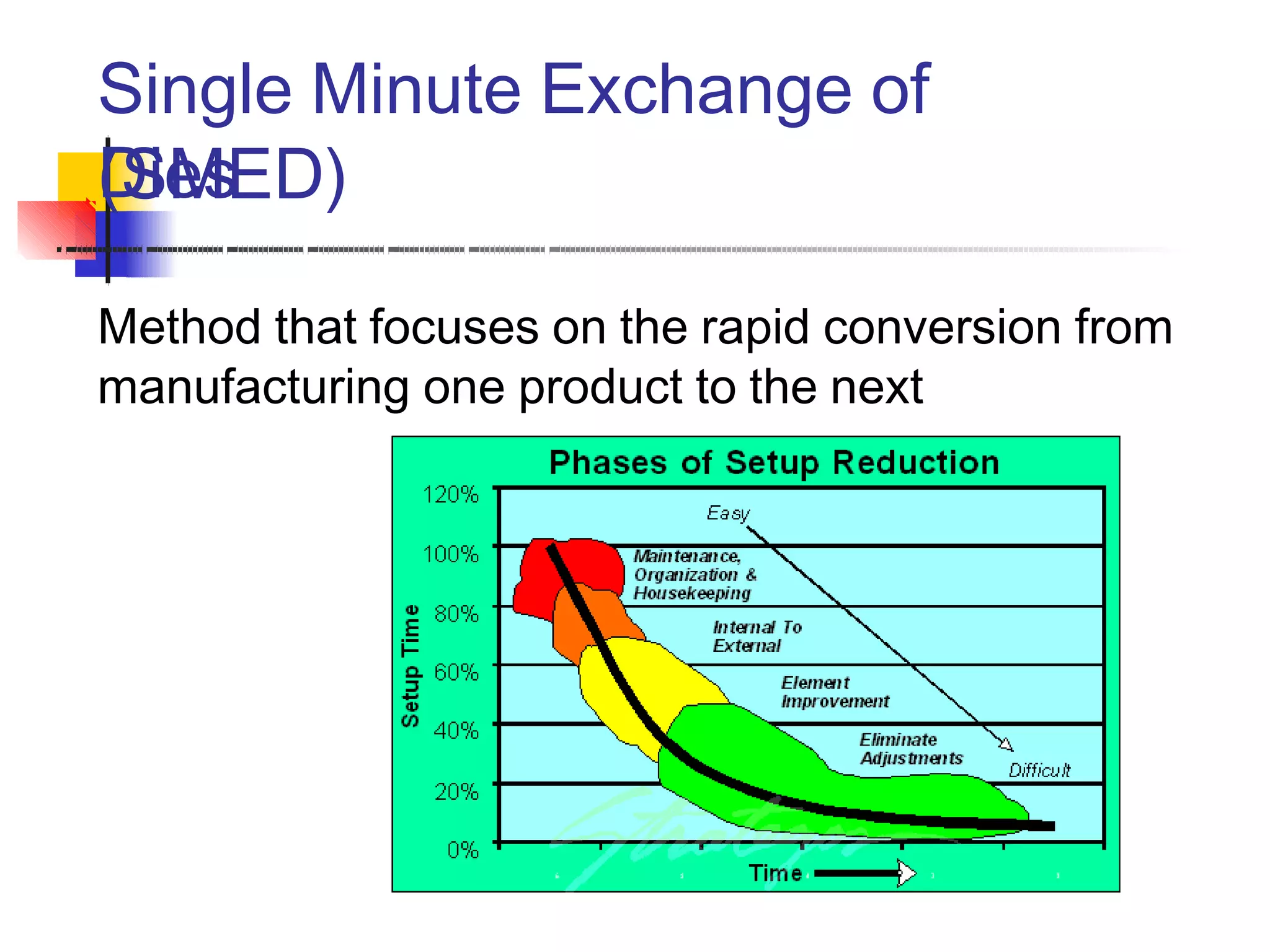

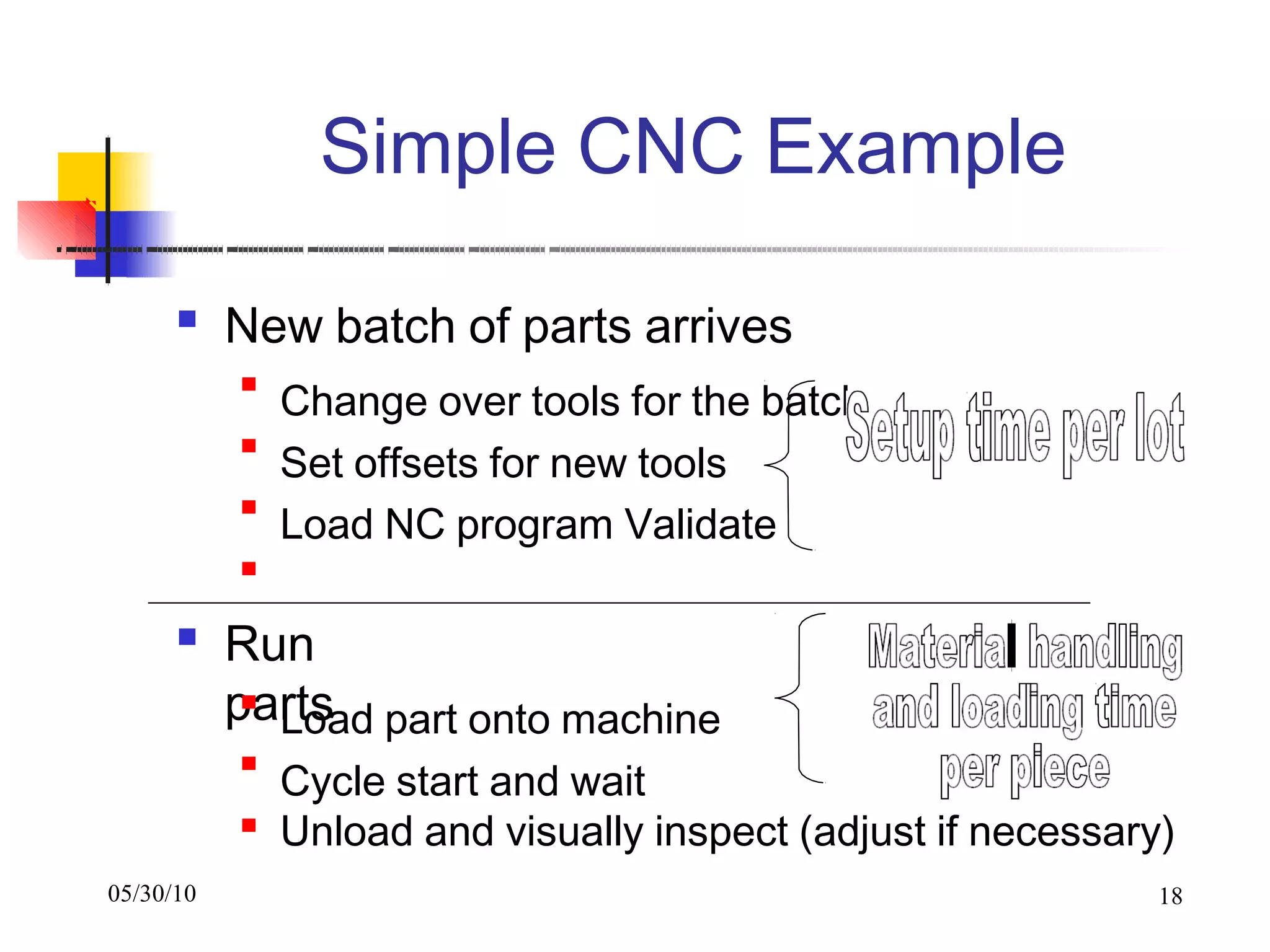

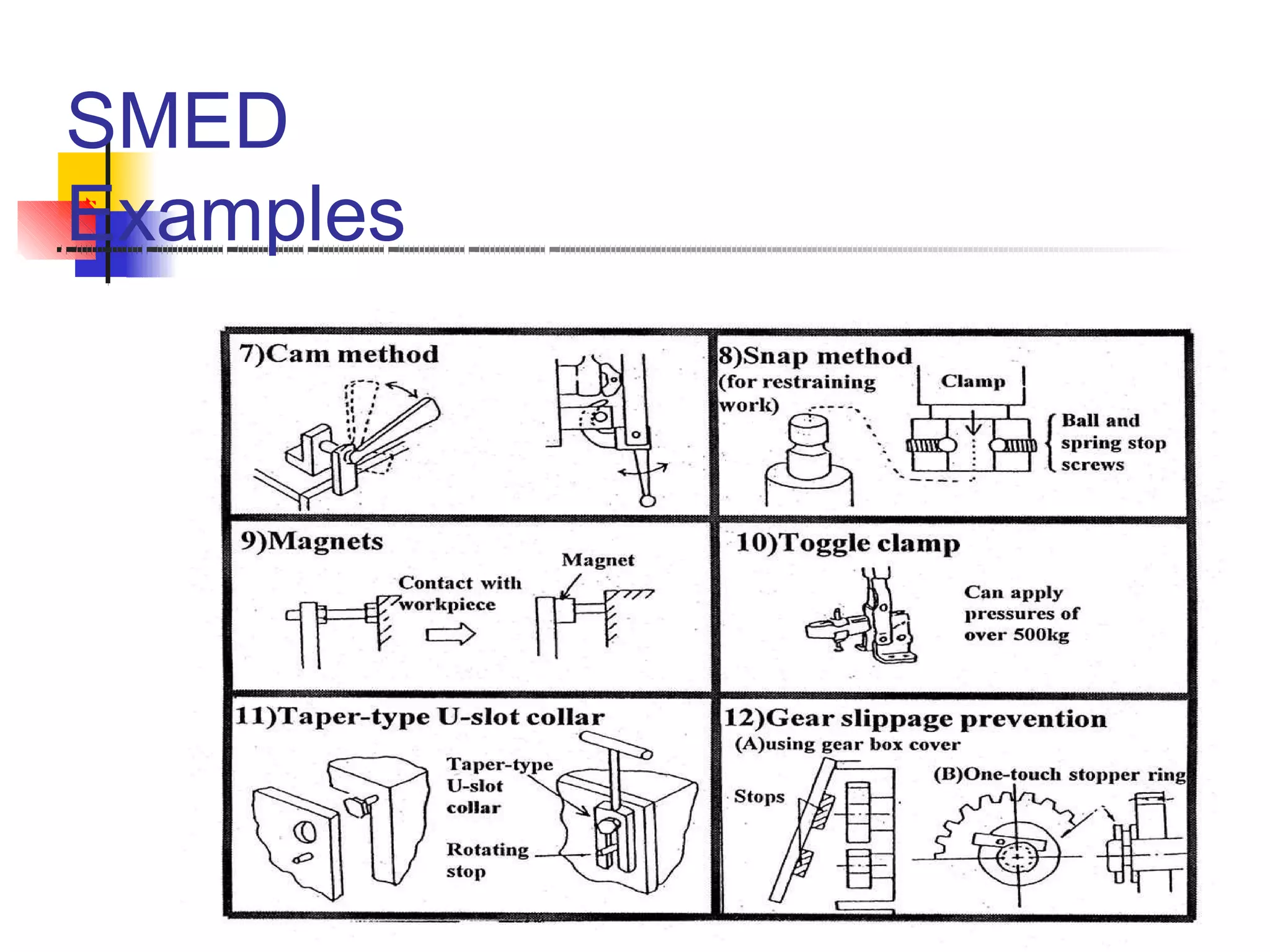

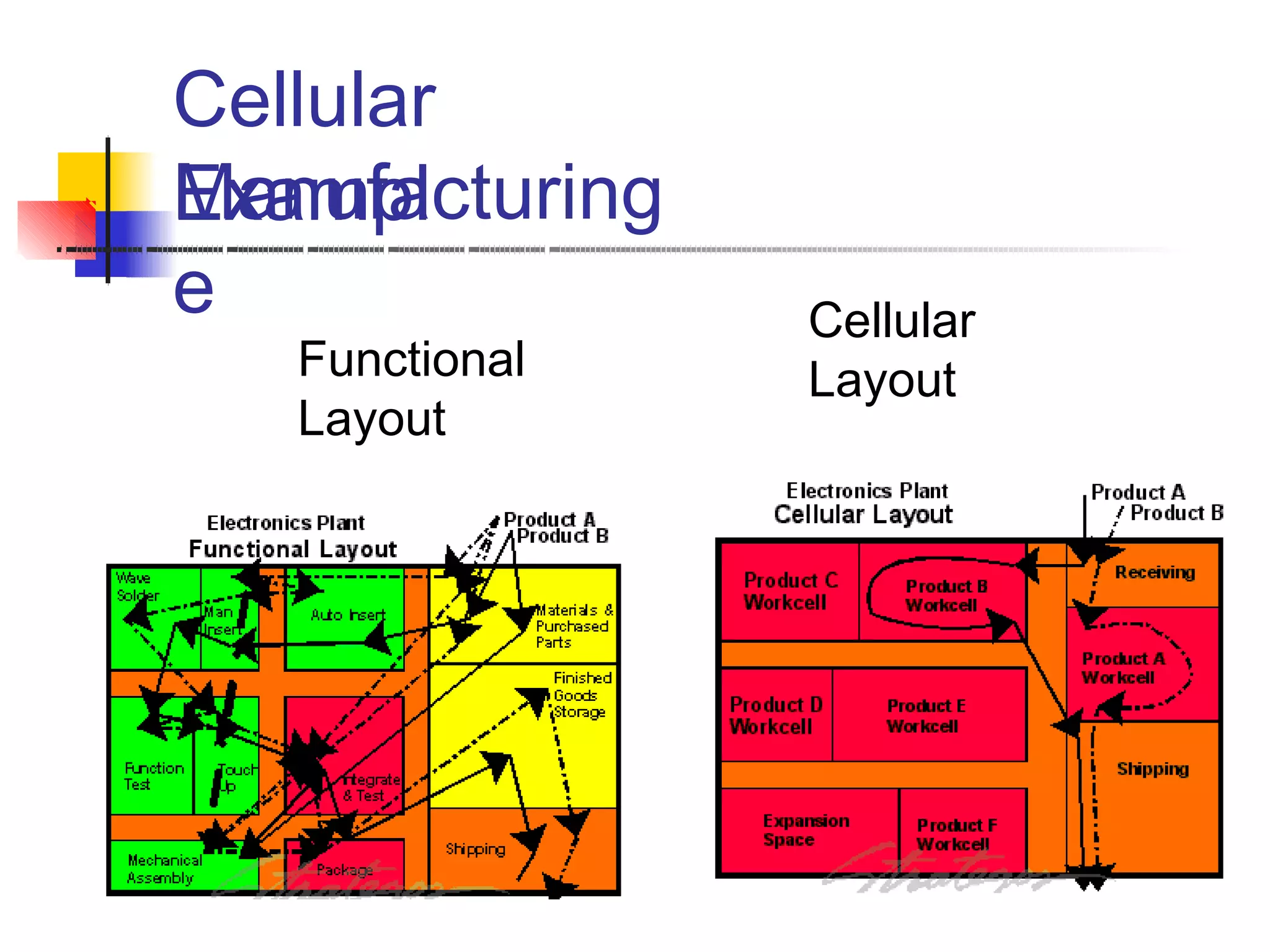

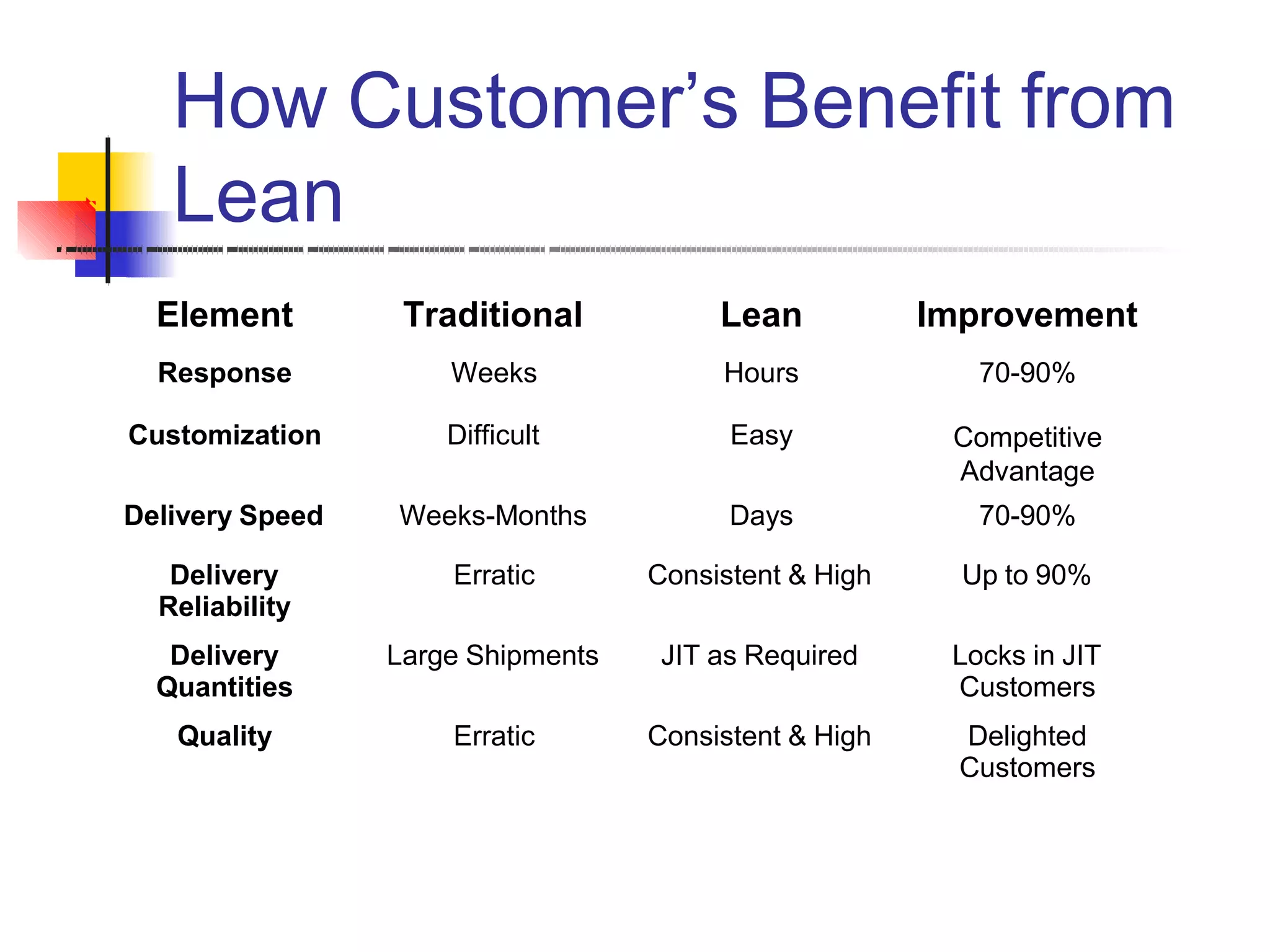

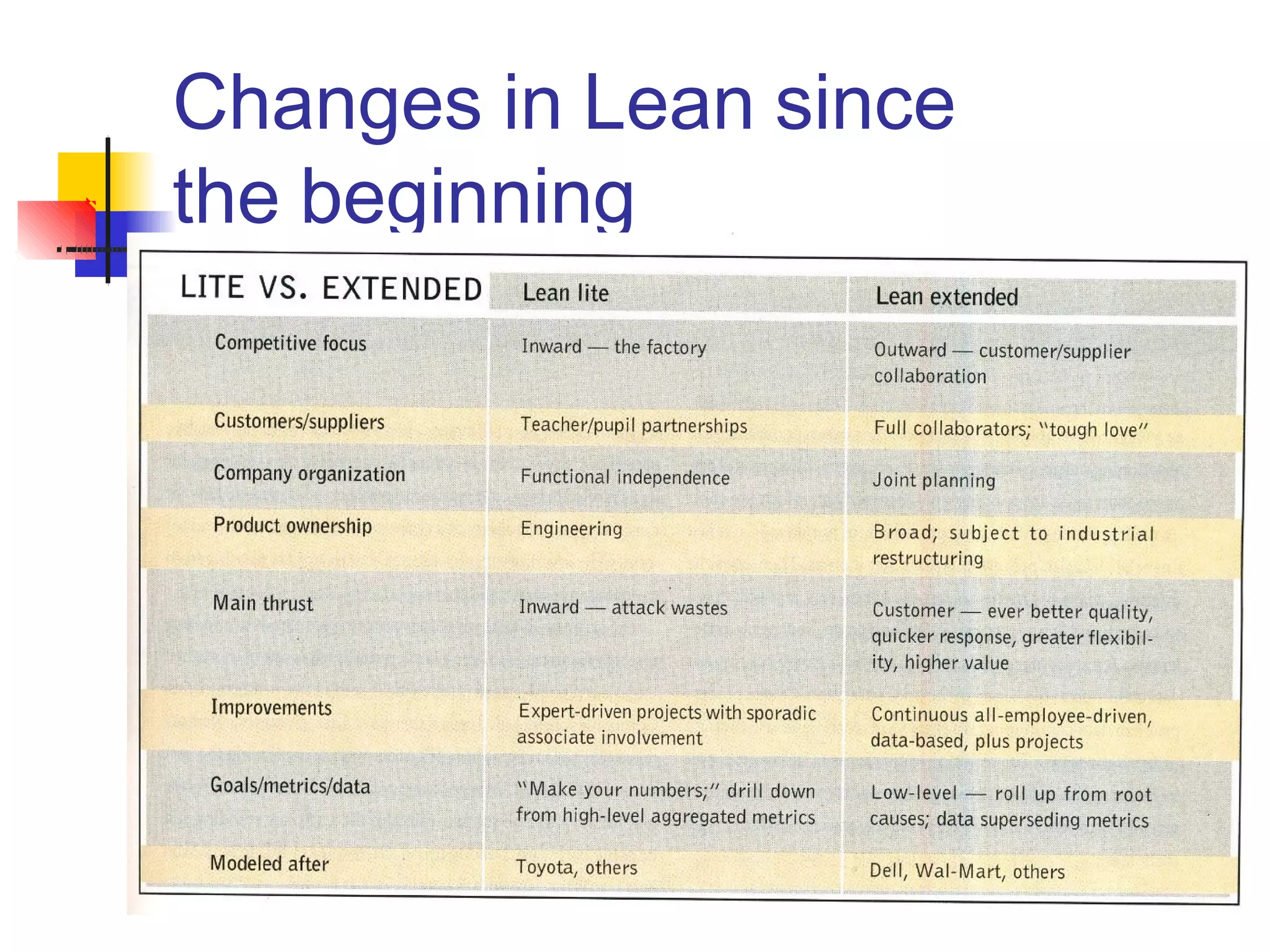

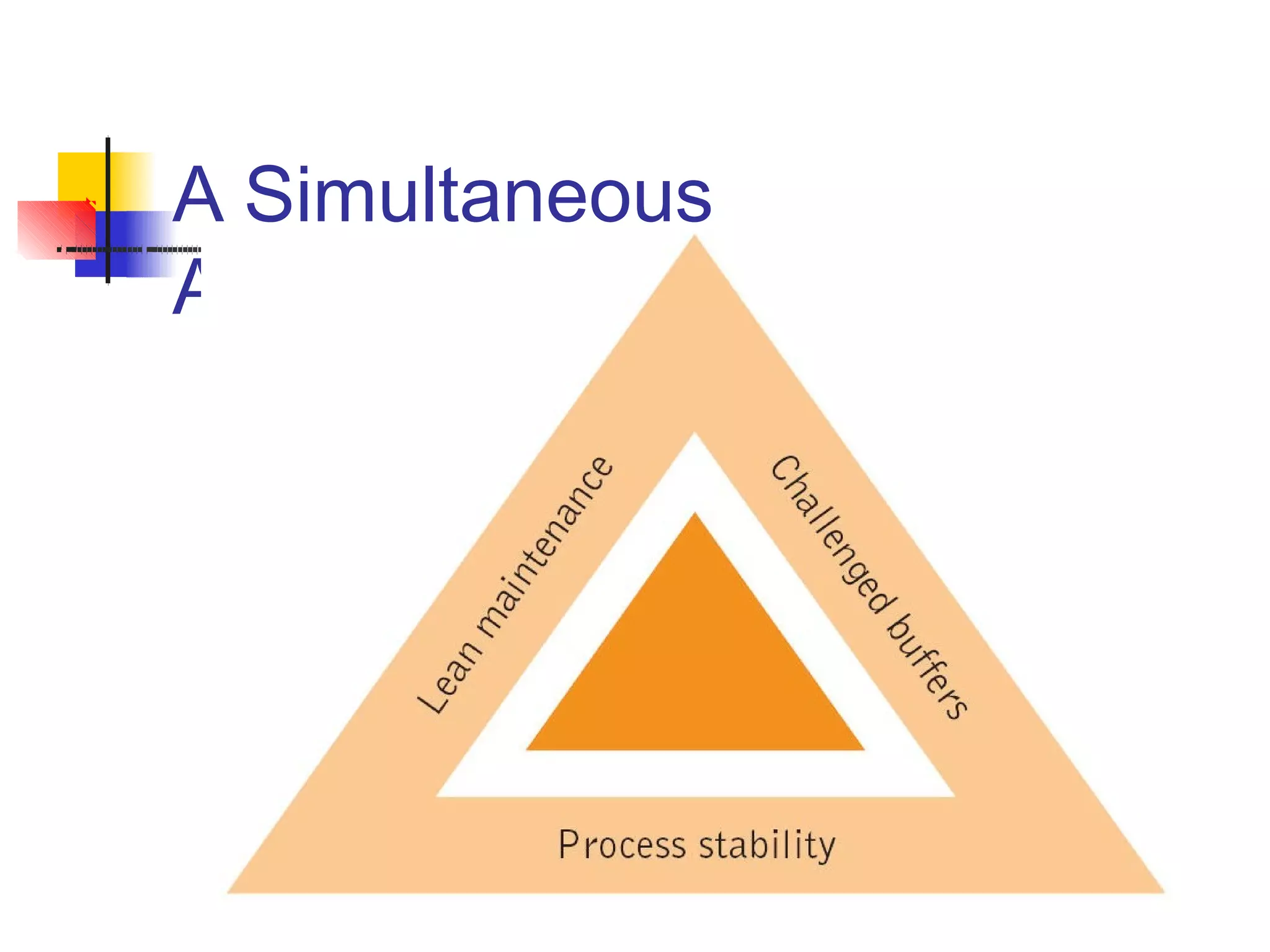

This document provides an overview of lean manufacturing. It discusses the Toyota Production System and lean techniques like 5S, single minute exchange of dies (SMED), kanban, and cellular manufacturing. Implementing lean aims to eliminate waste and improve efficiency. Key benefits include increased productivity, reduced space/lead times, and improved quality and flexibility. The document also outlines how lean has evolved over time to incorporate strategies like six sigma, lean maintenance, and its application in various industries.