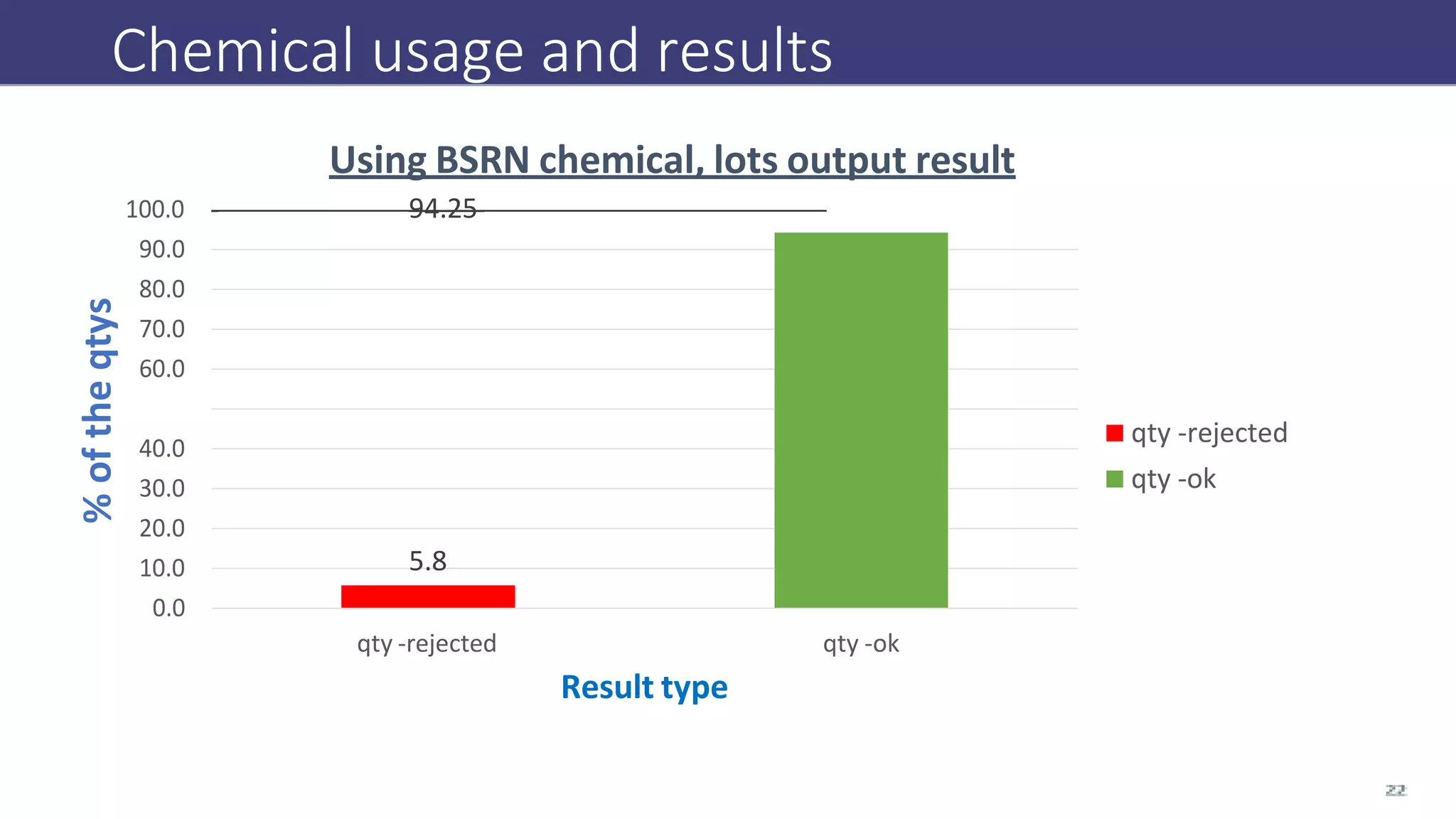

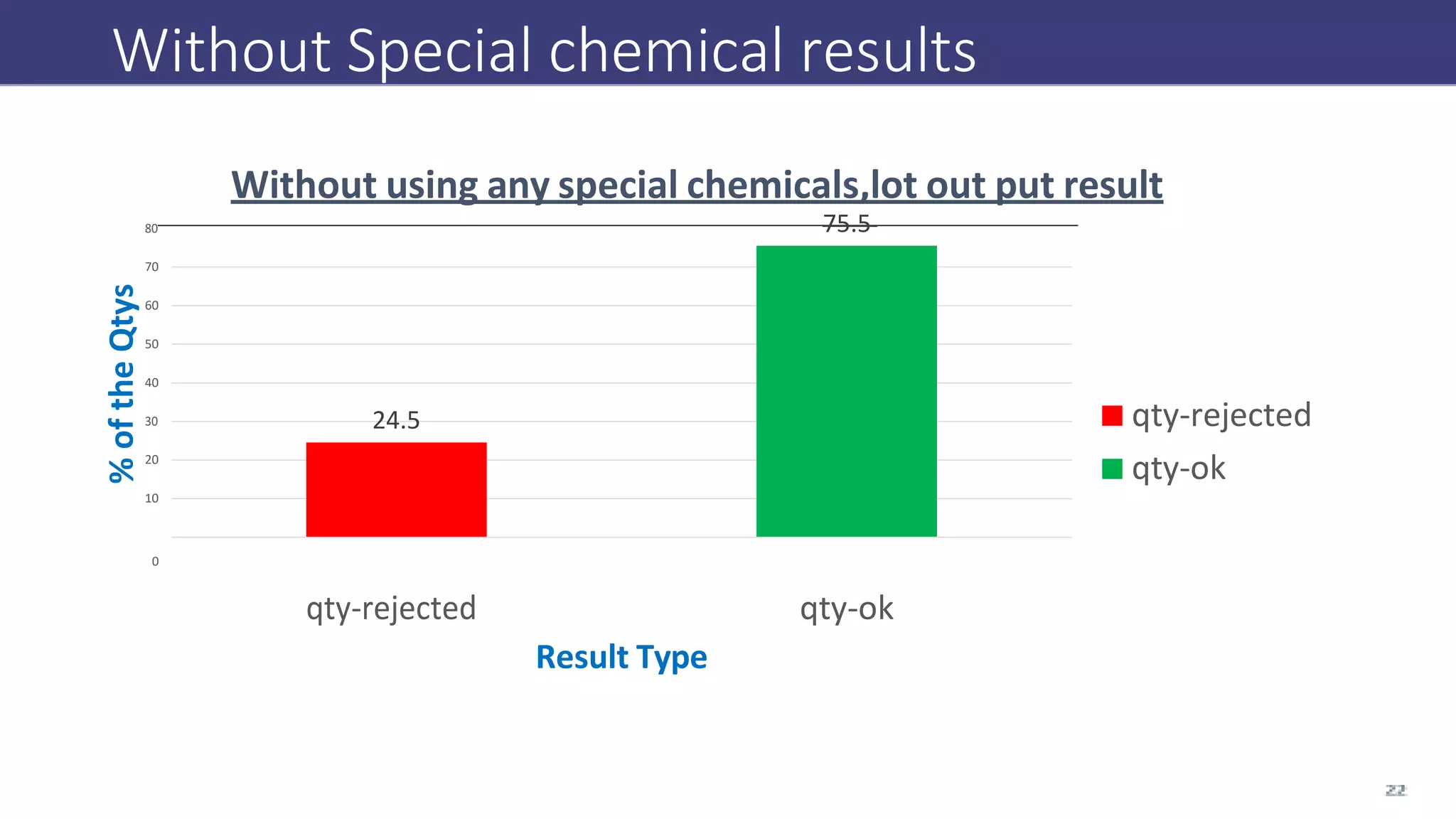

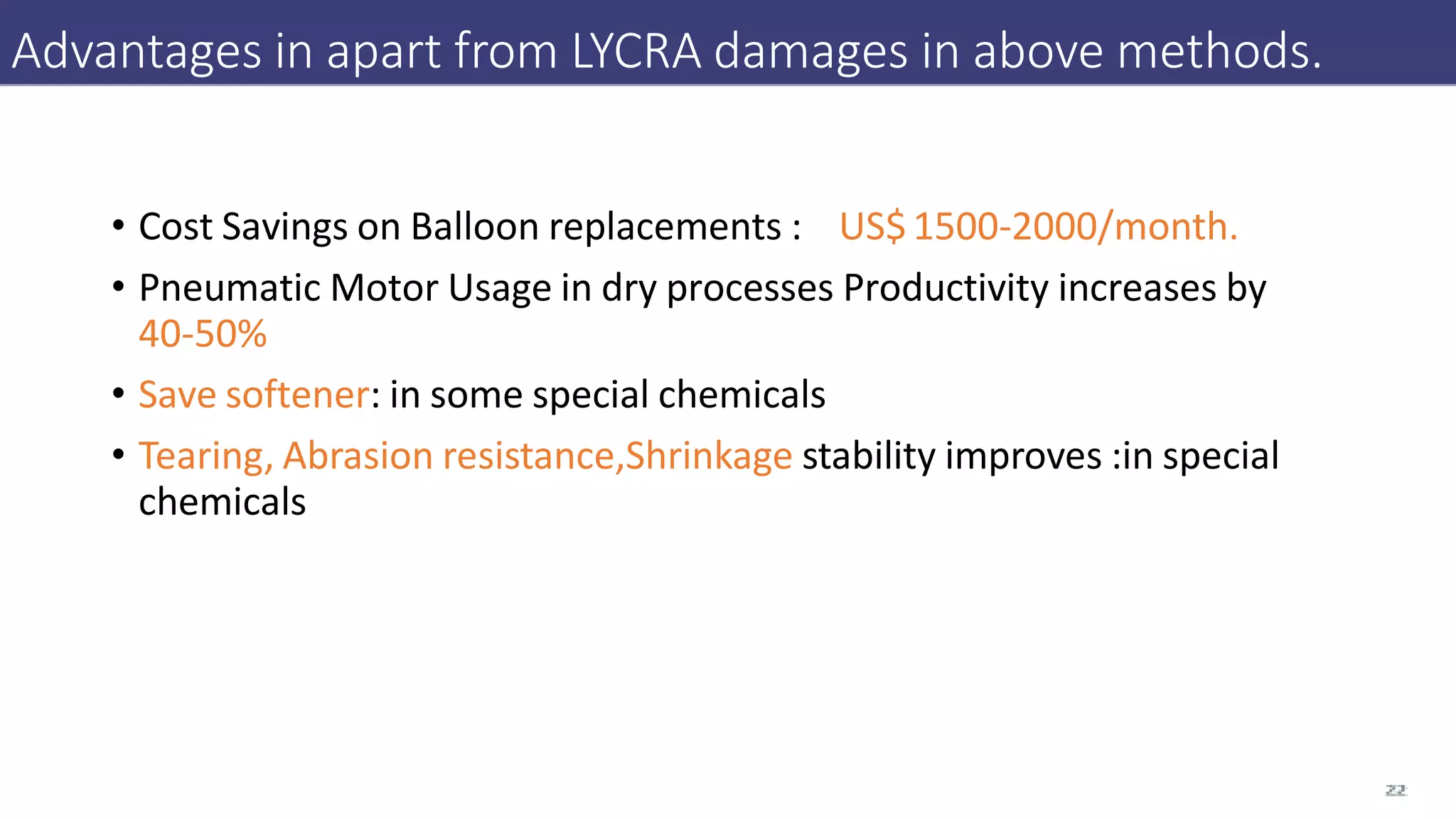

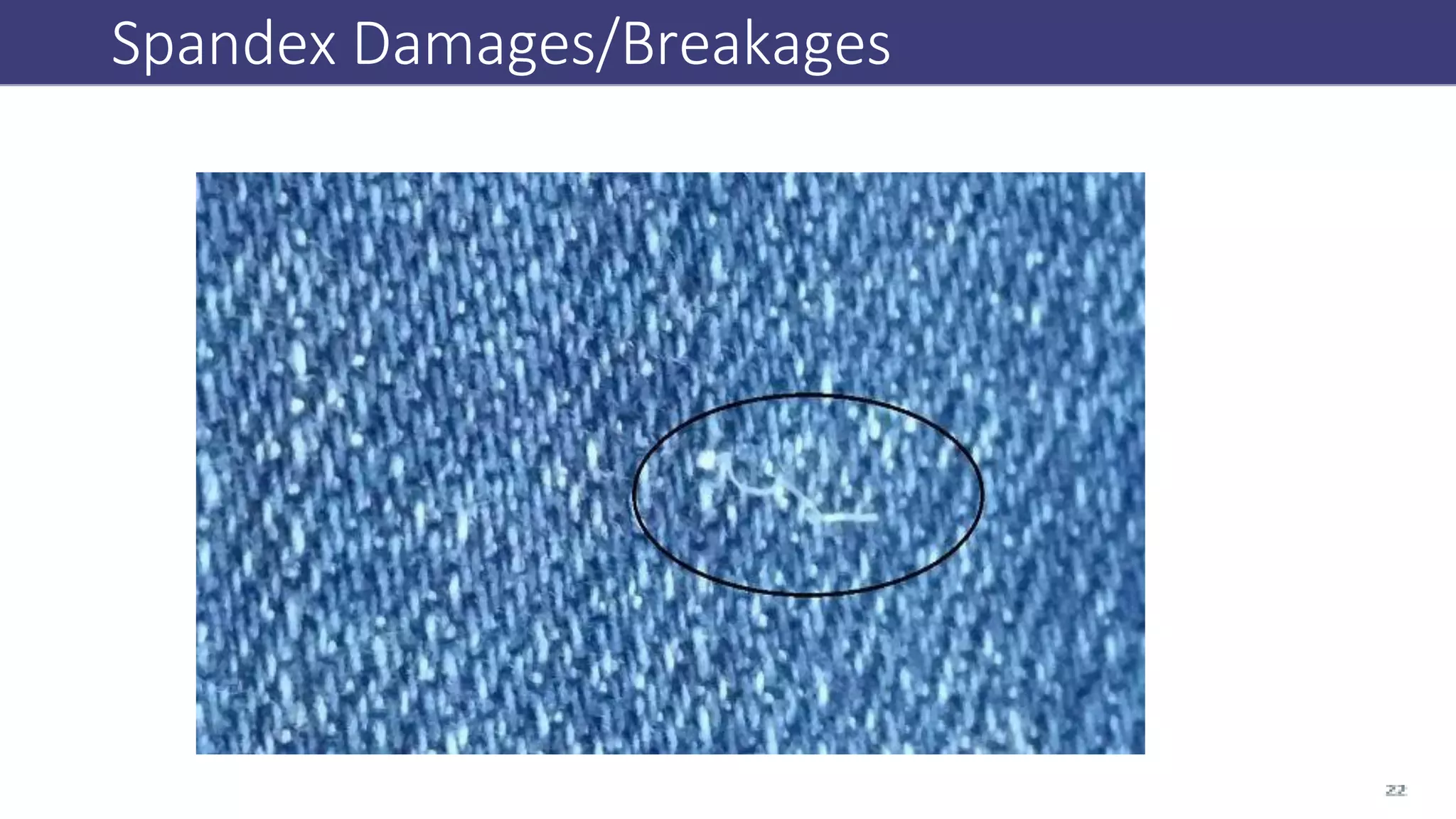

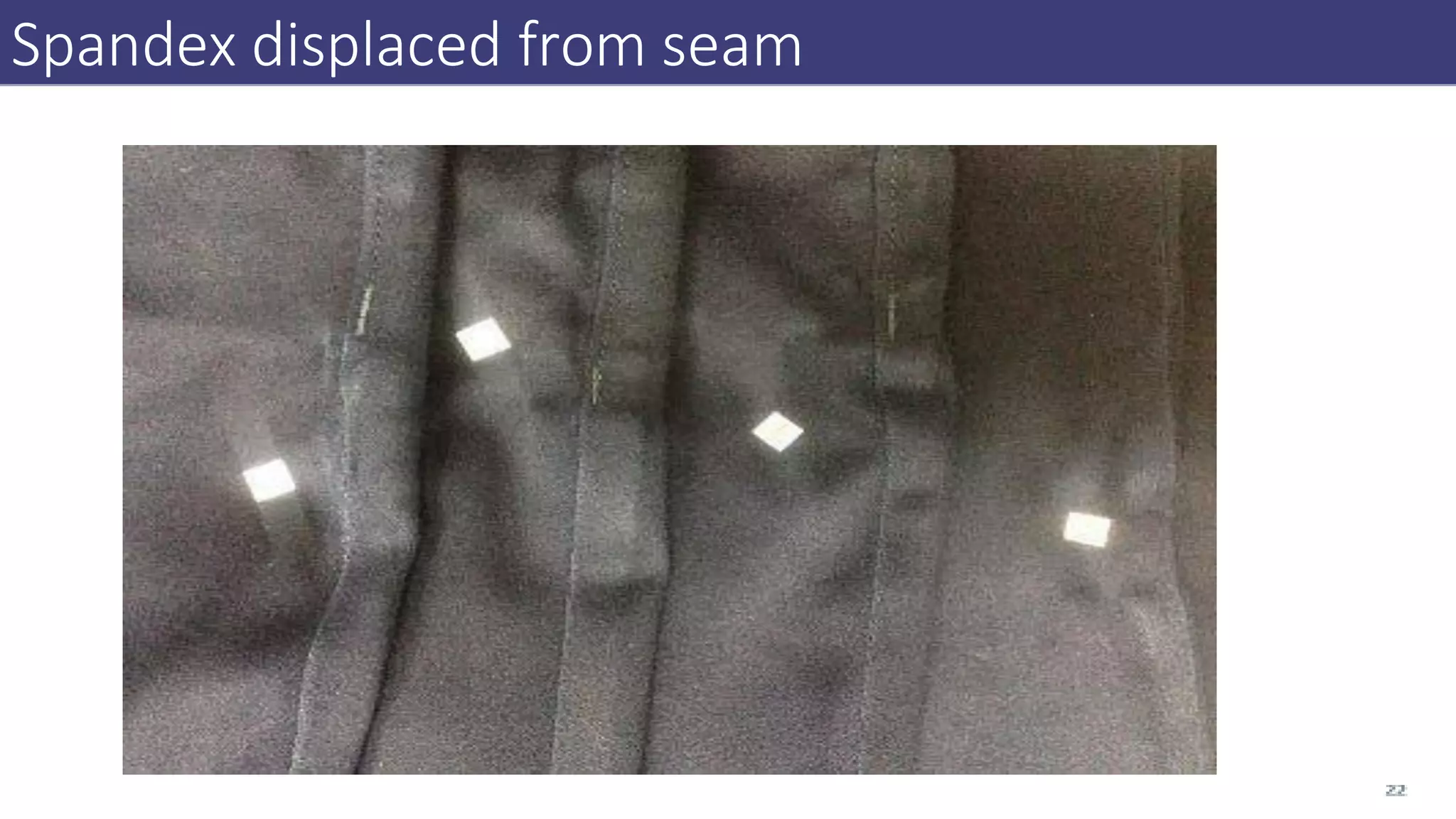

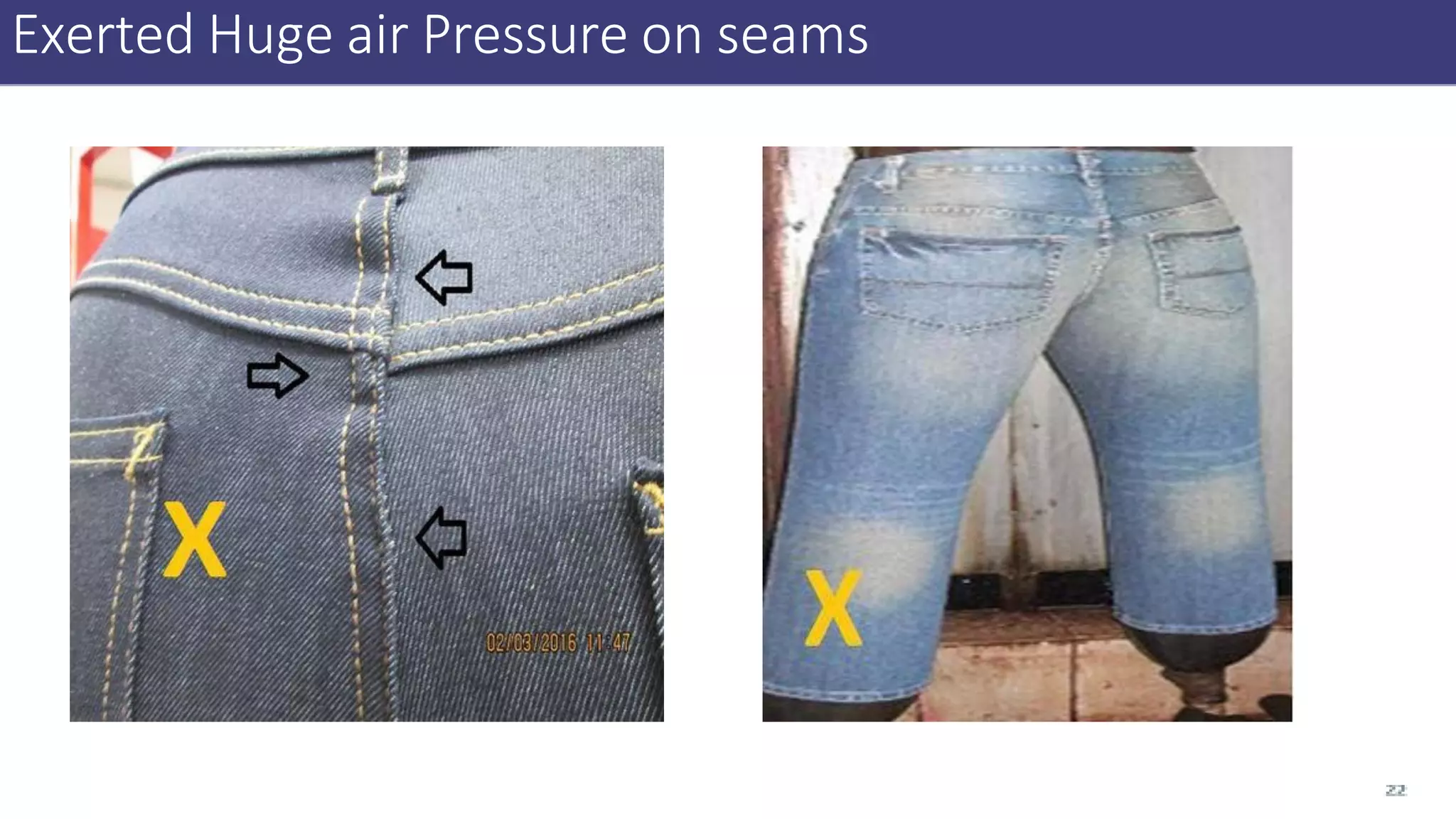

The document discusses various forms of lycra deformation in garments, including spandex damages, displacement from seams, and crinkle effects. It provides detailed precautions for washing and drying, emphasizing the importance of temperature control, reduced wash cycles, and specific chemical usage to prevent damages. Additionally, it highlights cost savings and productivity improvements achieved through optimized processing techniques and special chemicals.

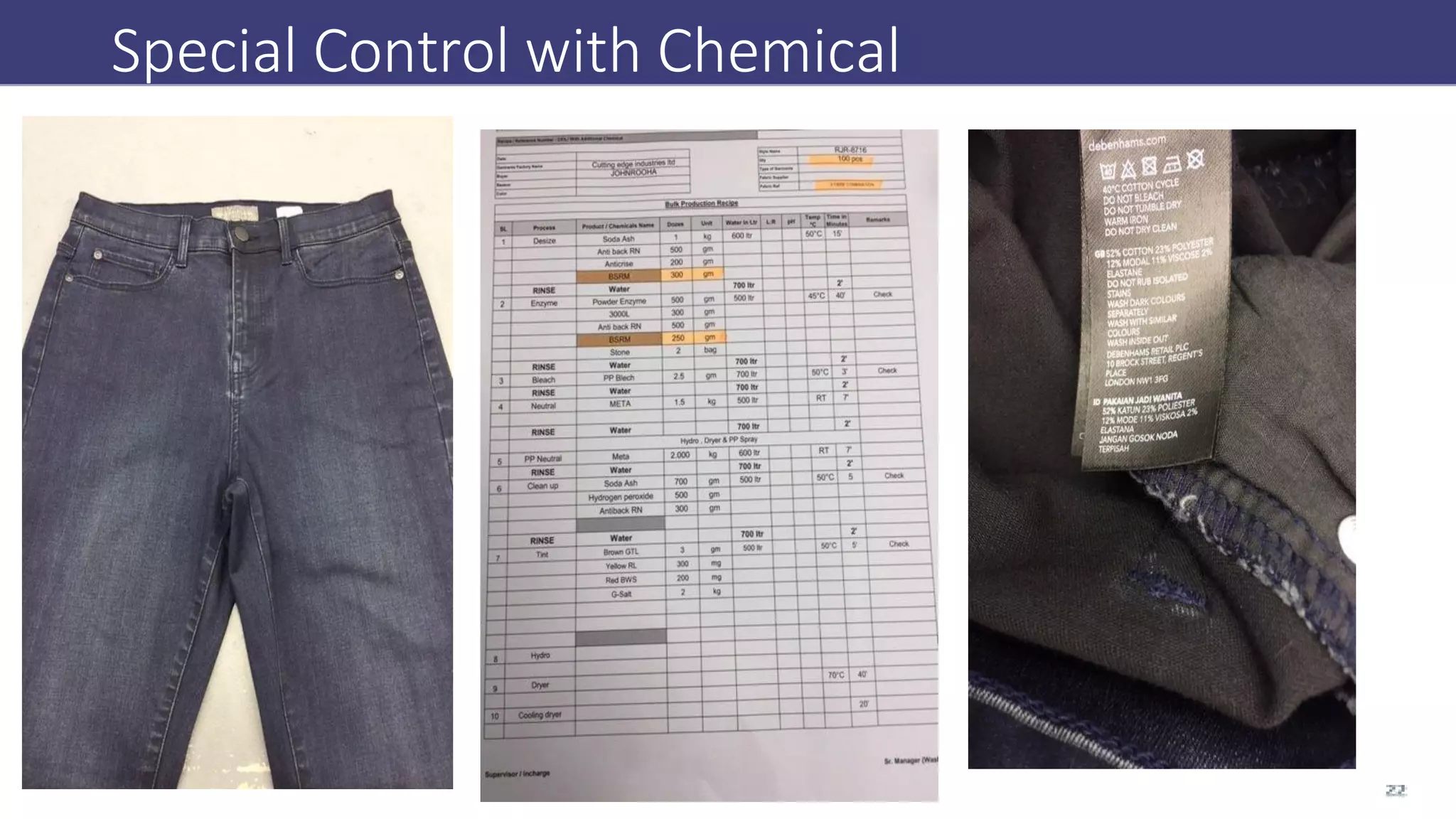

![Special Control with Chemical

1.Soft Polyurethane Emulsion- [Dicrylan BSRN from Huntsman]

2.Polyethylene Emulsion-[Evo Soft APE from Dystar]

3.Poly ethylene-[Protector KCL from GDS]

4. Inorganic salt with surfactants[Protector PCL from GDS]-in bleaching](https://image.slidesharecdn.com/lycravoidandprecautiontoavoidthoseinwashing-final-210807103846/75/Lycra-void-damage-and-precaution-to-avoid-those-in-washing-13-2048.jpg)