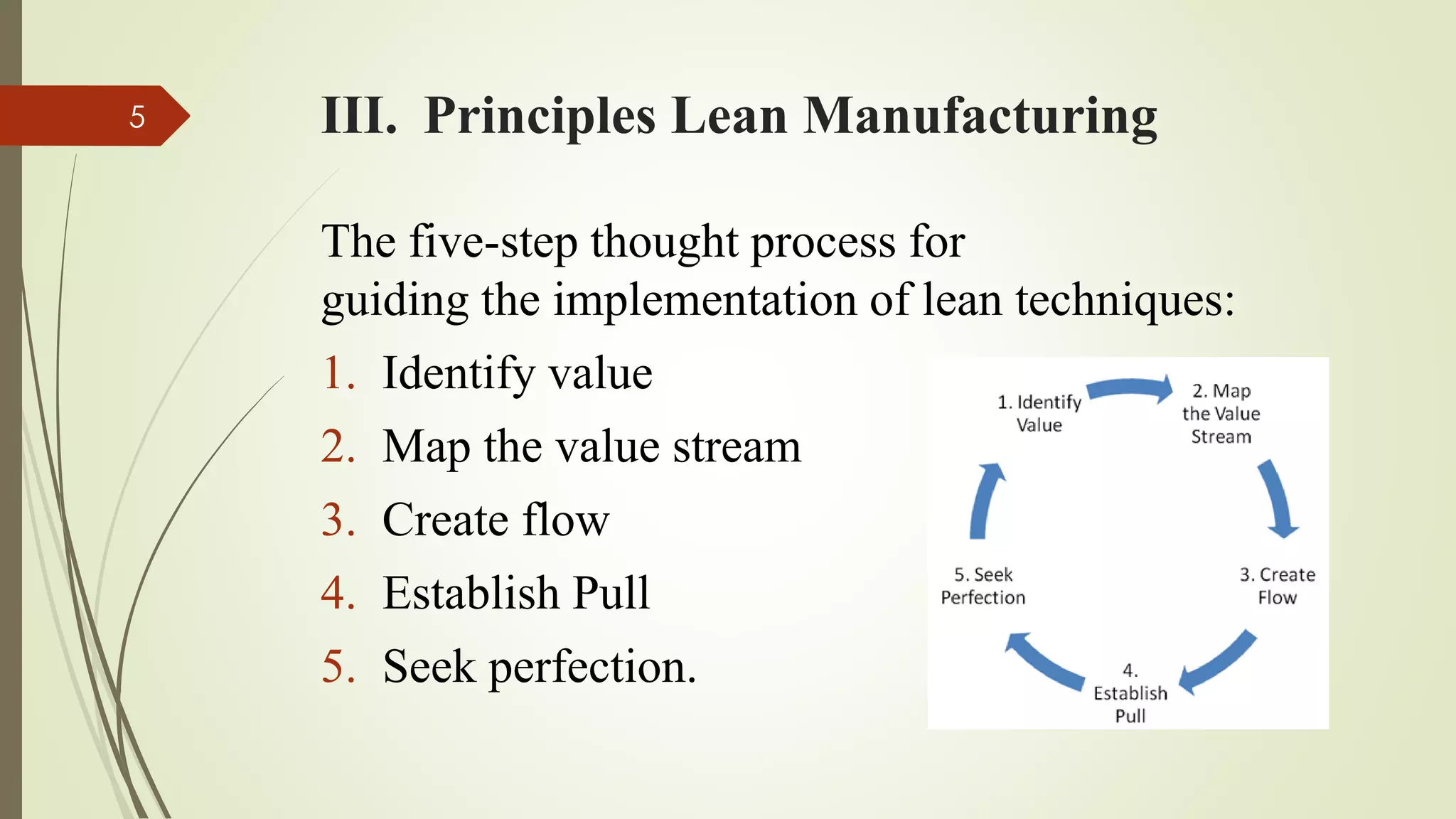

This document provides an overview of lean manufacturing. It defines lean manufacturing as a method to minimize waste and improve efficiency in manufacturing without reducing productivity. The objectives of lean manufacturing are outlined as eliminating non-value-added activities, minimizing work-in-process inventory, meeting customer demand on time, and creating flexibility. Key lean principles and methodologies are also summarized, including identifying value, mapping the value stream, establishing flow and pull, and seeking perfection. Common types of waste and tools such as 5S, standard work, and just-in-time production are also briefly described.