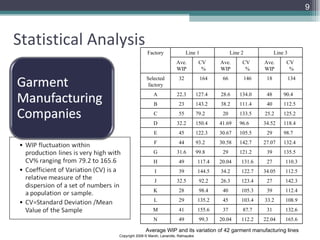

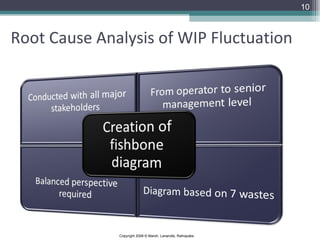

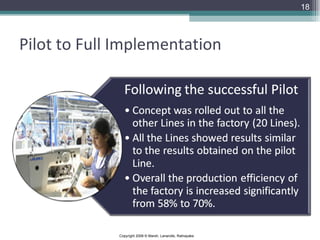

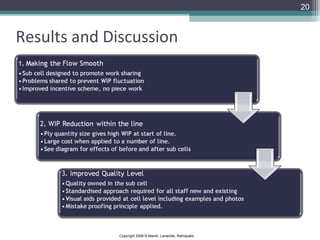

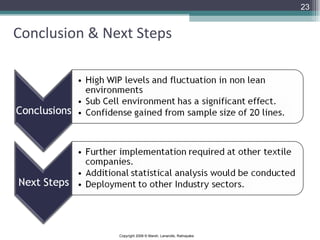

The paper discusses the experiences and achievements of James Marsh, Vijitha Ratnayake, and Gamini Lanarolle in applying lean Six Sigma principles within Sri Lanka's garment industry, which constitutes over 43% of the country's exports. They highlight issues such as high work-in-progress (WIP) levels and the need for improved labor productivity and flexibility to address changing customer demands. The authors outline their methodologies, including training and the implementation of lean tools to optimize processes and enhance production efficiency.