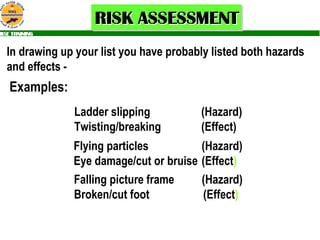

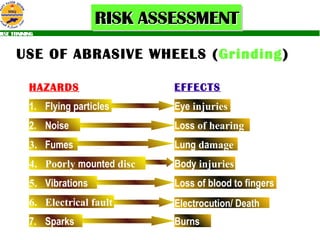

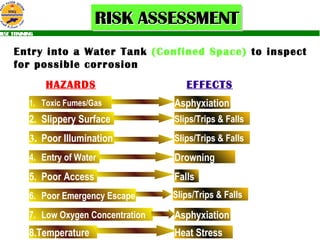

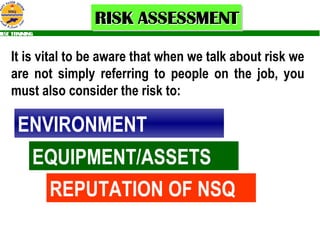

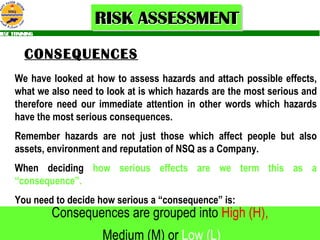

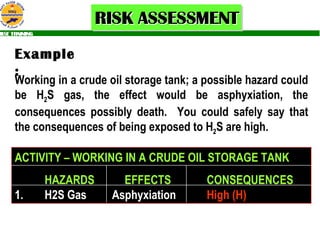

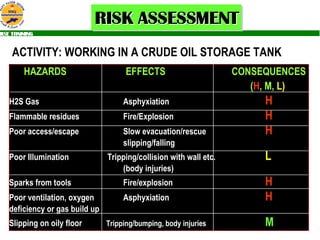

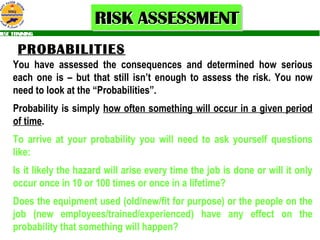

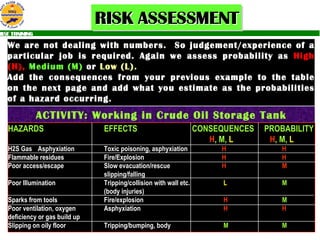

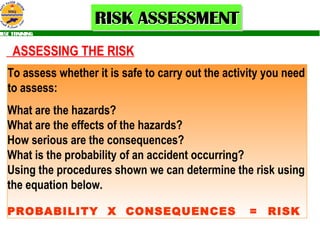

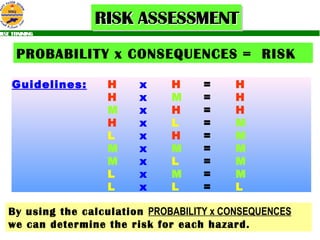

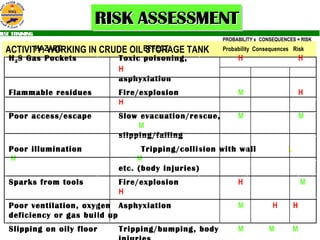

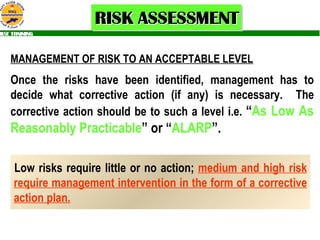

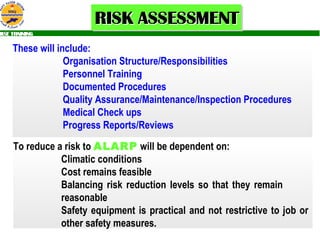

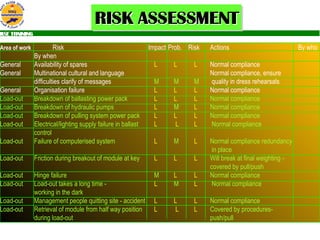

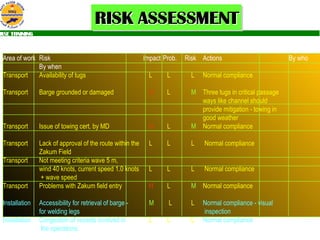

The document provides an overview of risk assessment for NSQ's HSE training programme. It aims to identify hazards, evaluate risks, and implement controls to reduce risks to an acceptable level. Key steps include looking for hazards, deciding who could be affected and how, evaluating risks, recording assessments, and reviewing assessments over time as conditions change. Hazards may arise from tasks, equipment, location or other factors. The consequences and probabilities of hazards are analyzed to determine the level of risk, and corrective actions are taken as needed to reduce risks to "as low as reasonably practicable."