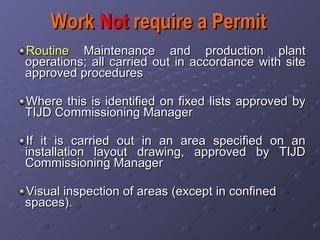

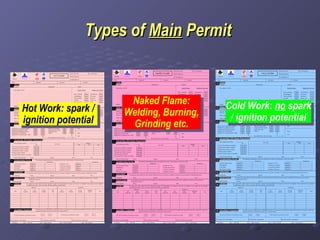

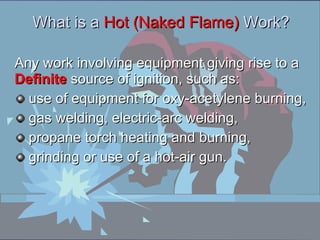

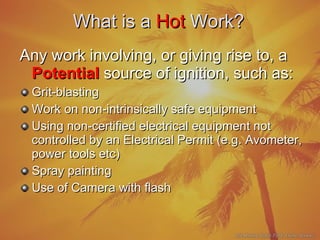

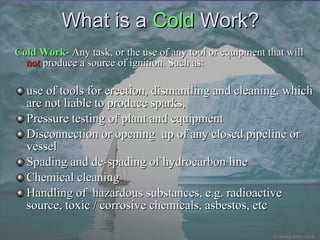

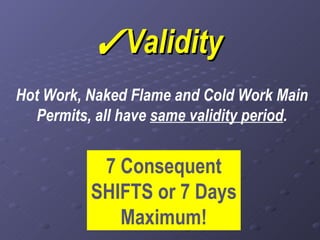

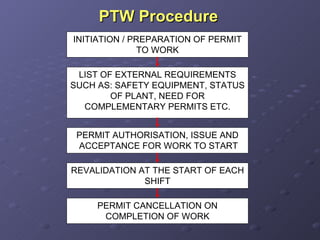

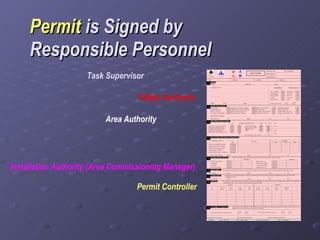

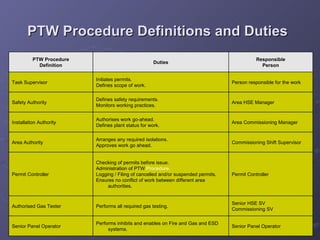

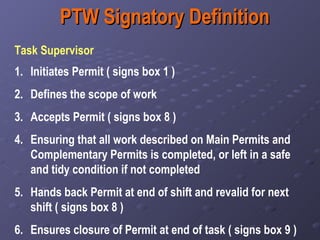

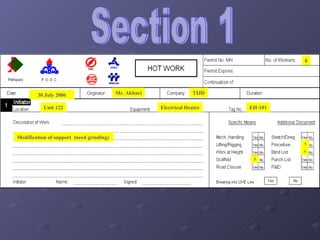

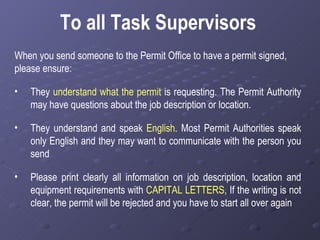

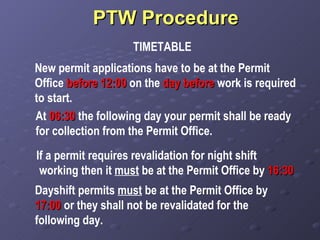

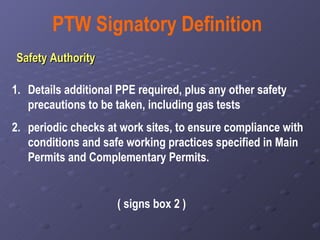

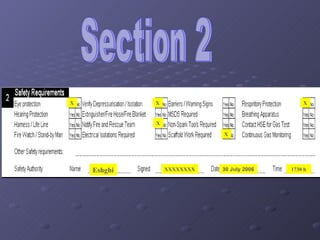

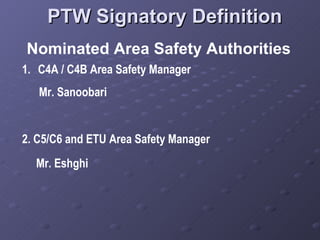

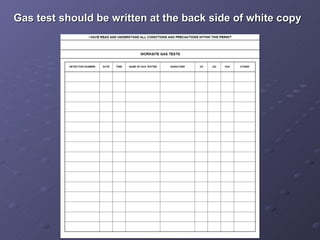

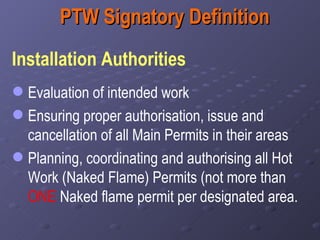

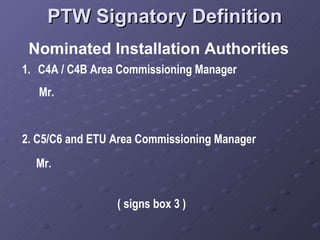

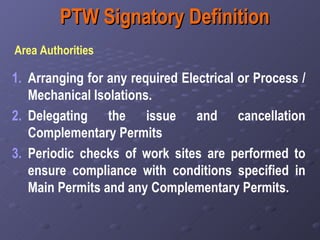

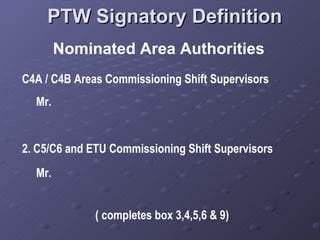

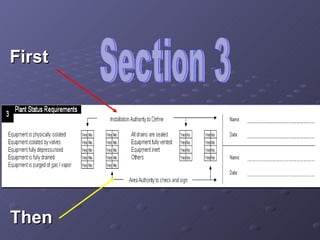

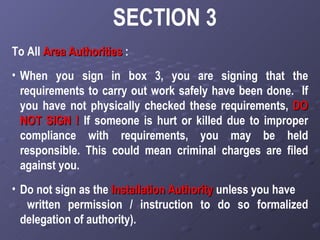

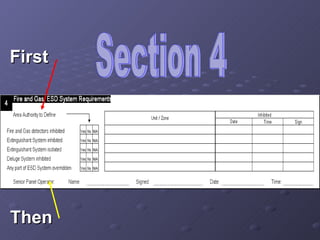

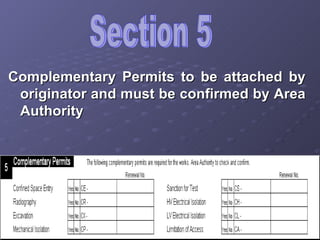

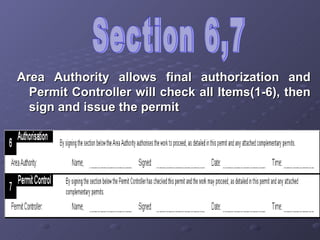

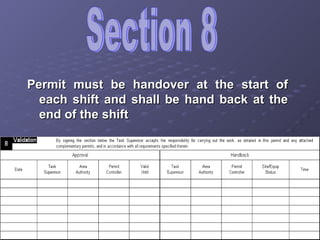

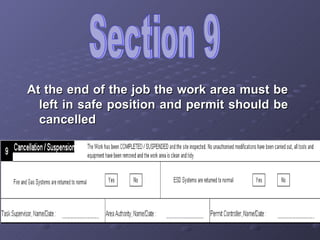

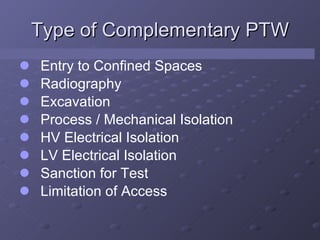

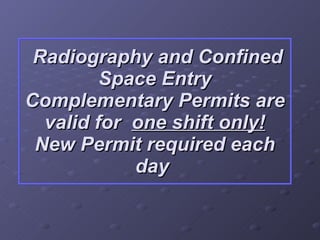

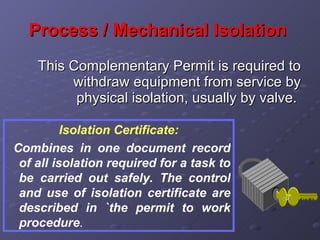

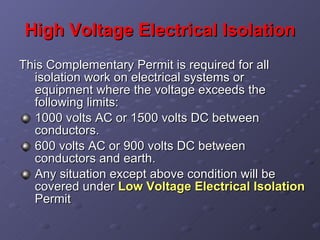

The document discusses permit to work (PTW) procedures at an NGI training center. It defines what a PTW is, its purpose of ensuring work is planned and hazards identified, and that it is a legal document. It describes what types of work require a PTW, including hot work and cold work. It outlines the PTW process including initiation, authorization, cancellation. It defines roles and responsibilities of personnel involved in the PTW process. Finally, it discusses complementary permits that may be required for different types of work, such as electrical isolation or confined space entry.