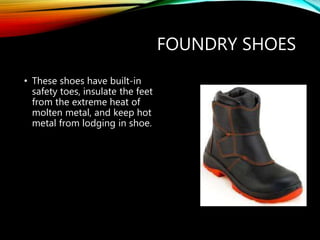

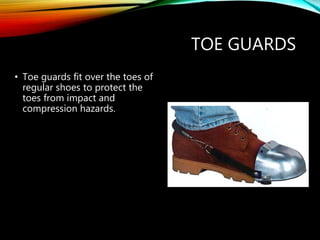

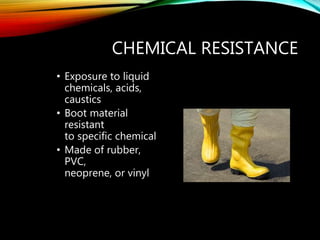

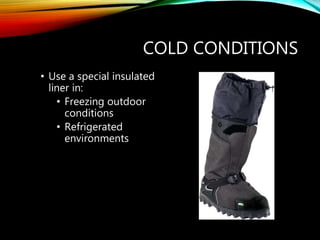

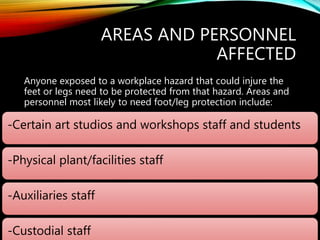

The document outlines the importance of foot and leg protection in workplaces, detailing the potential hazards that necessitate the use of personal protective equipment (PPE). It provides information on various types of protective footwear and the training required for employees to ensure safe usage. Additionally, it highlights the critical need for assessments on hazards and the appropriate selection of PPE to mitigate risks associated with foot and leg injuries.