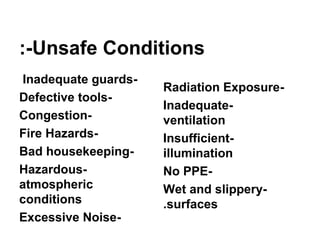

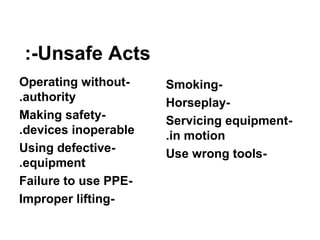

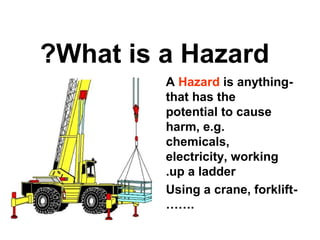

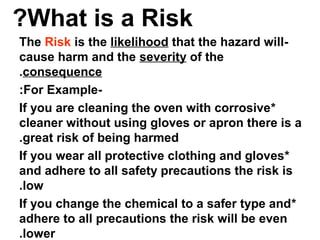

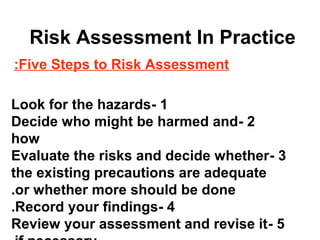

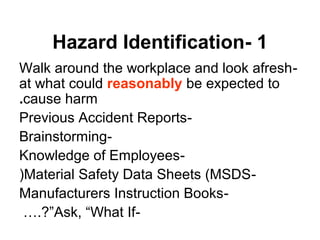

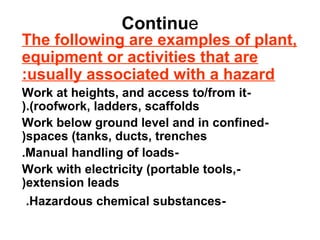

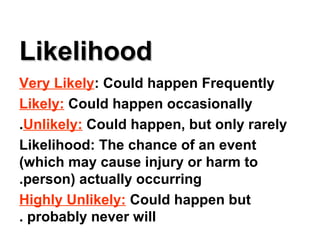

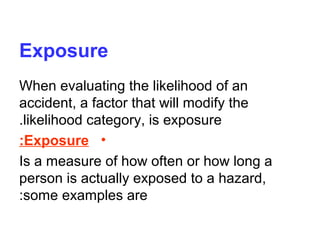

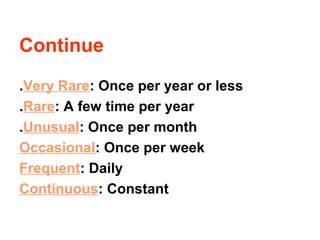

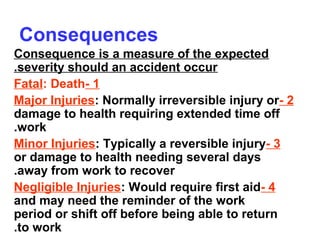

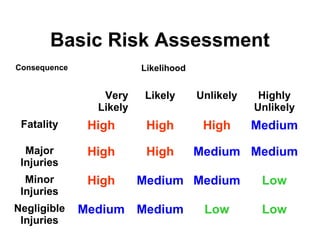

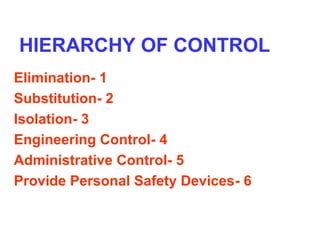

This document provides an introduction to risk assessment and accident prevention. It defines an accident and outlines the main causes as unsafe conditions and unsafe acts. Various hazards are identified and examples of risks are described. The five steps of risk assessment involve identifying hazards, determining who may be harmed, evaluating risks, recording findings, and reviewing assessments. Likelihood and consequences of risks are evaluated on scales to determine the overall risk level, with the goal of implementing controls to reduce risks.