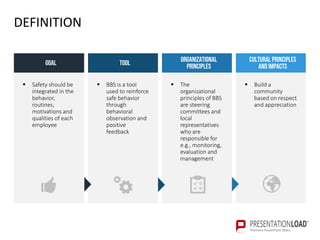

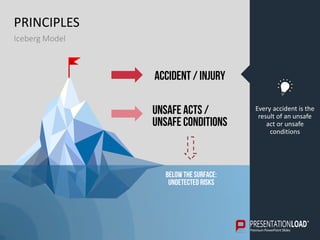

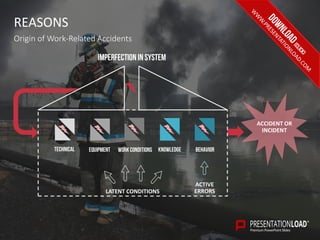

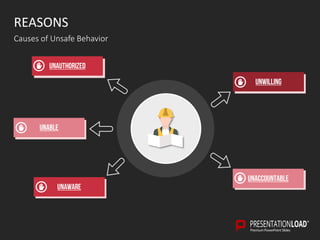

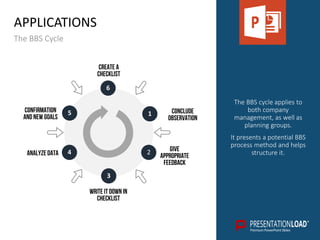

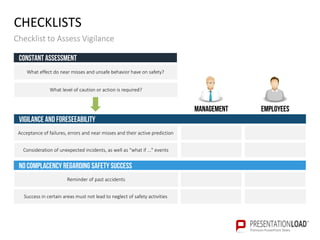

The document discusses behavior-based safety (BBS), emphasizing that 85-90% of workplace accidents are due to unsafe behaviors, which can be mitigated by applying Heinrich's law. It outlines the principles and applications of BBS, including the importance of organizational and cultural factors in promoting safety, as well as preventive measures to reduce accidents. The content is structured around a checklist for assessing and improving safety behaviors in the workplace.