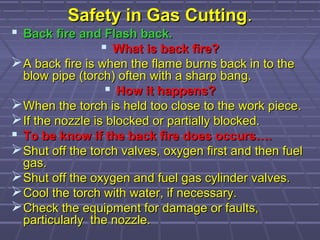

Safety in gas cutting requires understanding hazards, proper equipment use, and risk assessment. Key precautions include: knowing equipment parts and how to handle leaks, fires, or backfires; removing combustibles; using protective gear; and maintaining equipment. A risk assessment should consider training, permits, and job safety analysis to minimize dangers.