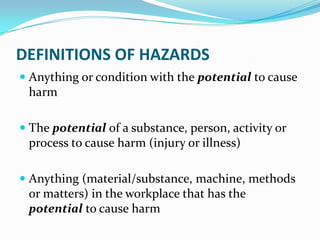

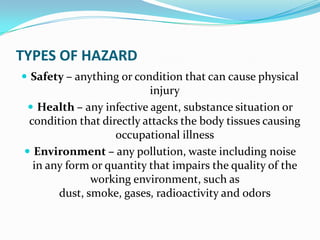

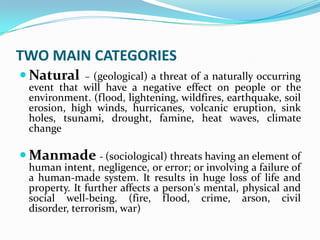

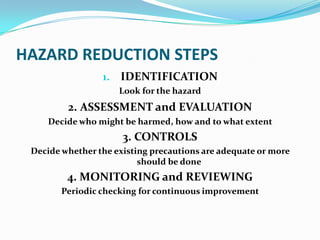

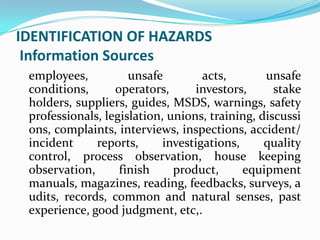

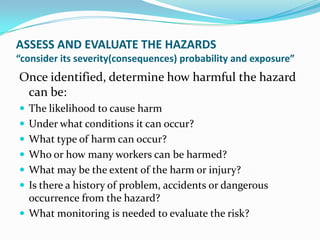

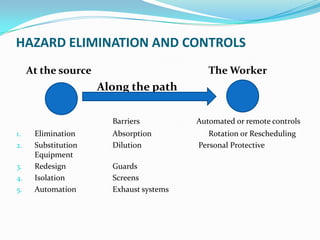

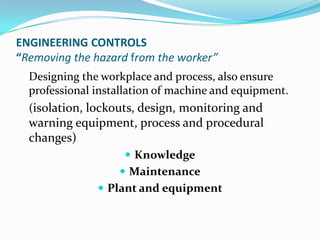

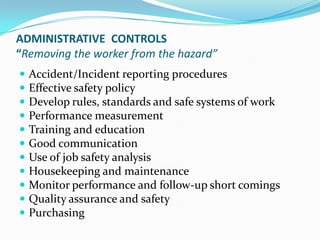

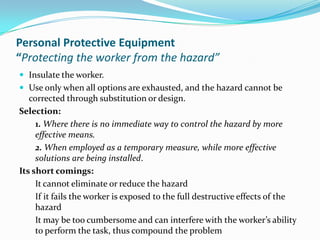

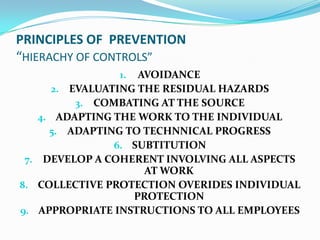

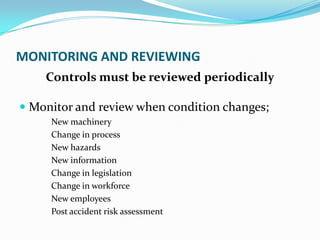

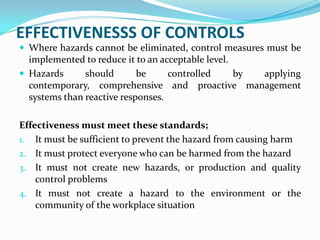

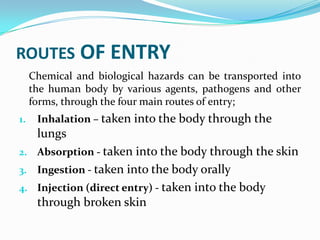

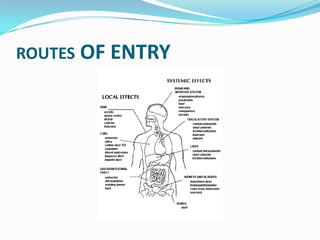

This document defines hazards and types of hazards, including safety, health, and environmental hazards. It outlines the main categories of hazards as natural and manmade. Other categories discussed include technological, behavioral, and specific physical, mechanical, chemical, biological, and psychological hazards. The document also covers definitions of risk, and the steps for identifying hazards, assessing and evaluating risks, implementing controls, and monitoring hazards. Engineering, administrative and personal protective equipment controls are described. Principles of prevention and routes of hazard entry are also summarized.