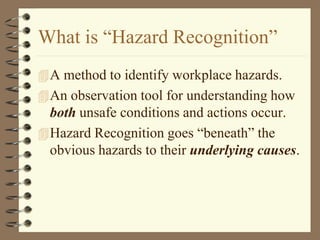

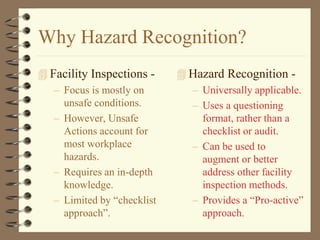

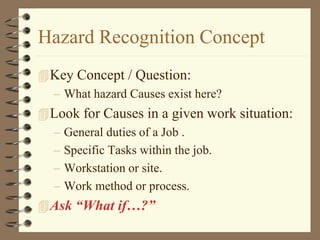

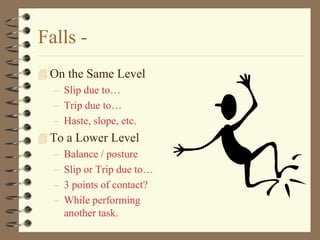

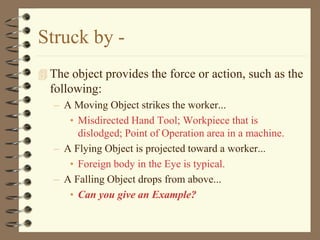

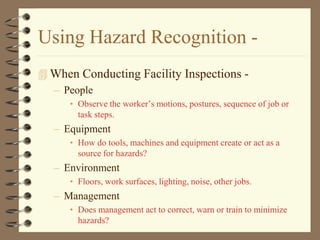

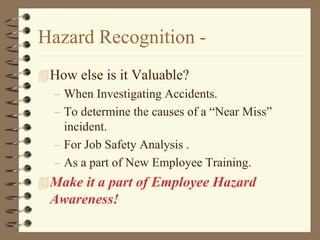

The document discusses hazard recognition training, focusing on identifying workplace hazards through observational techniques rather than checklists. It emphasizes understanding the underlying causes of unsafe conditions and actions, including various types of hazards such as falls, contact with objects, and over-exertion. The training aims to improve workplace safety by fostering proactive awareness and understanding of potential hazards and their prevention.