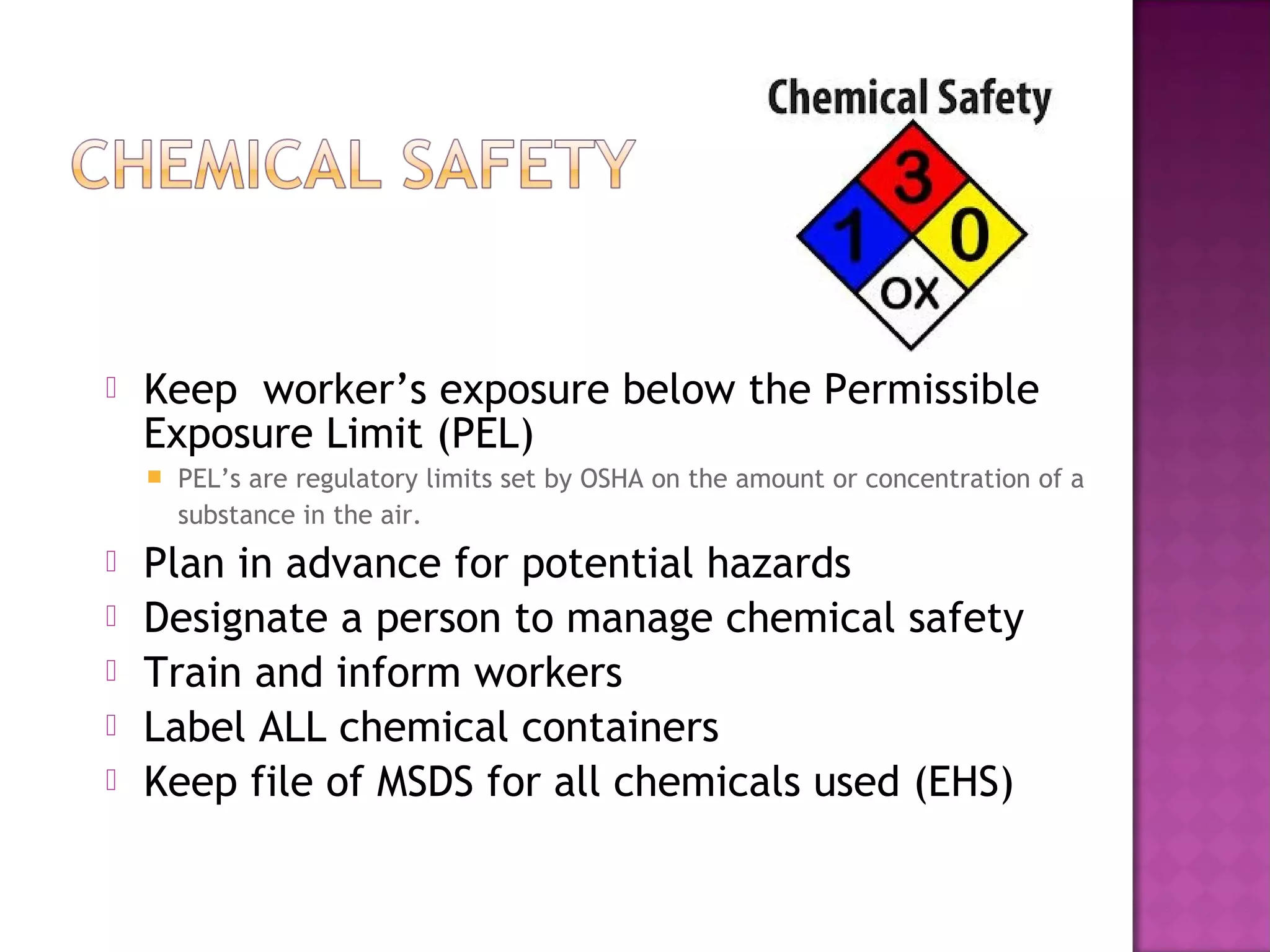

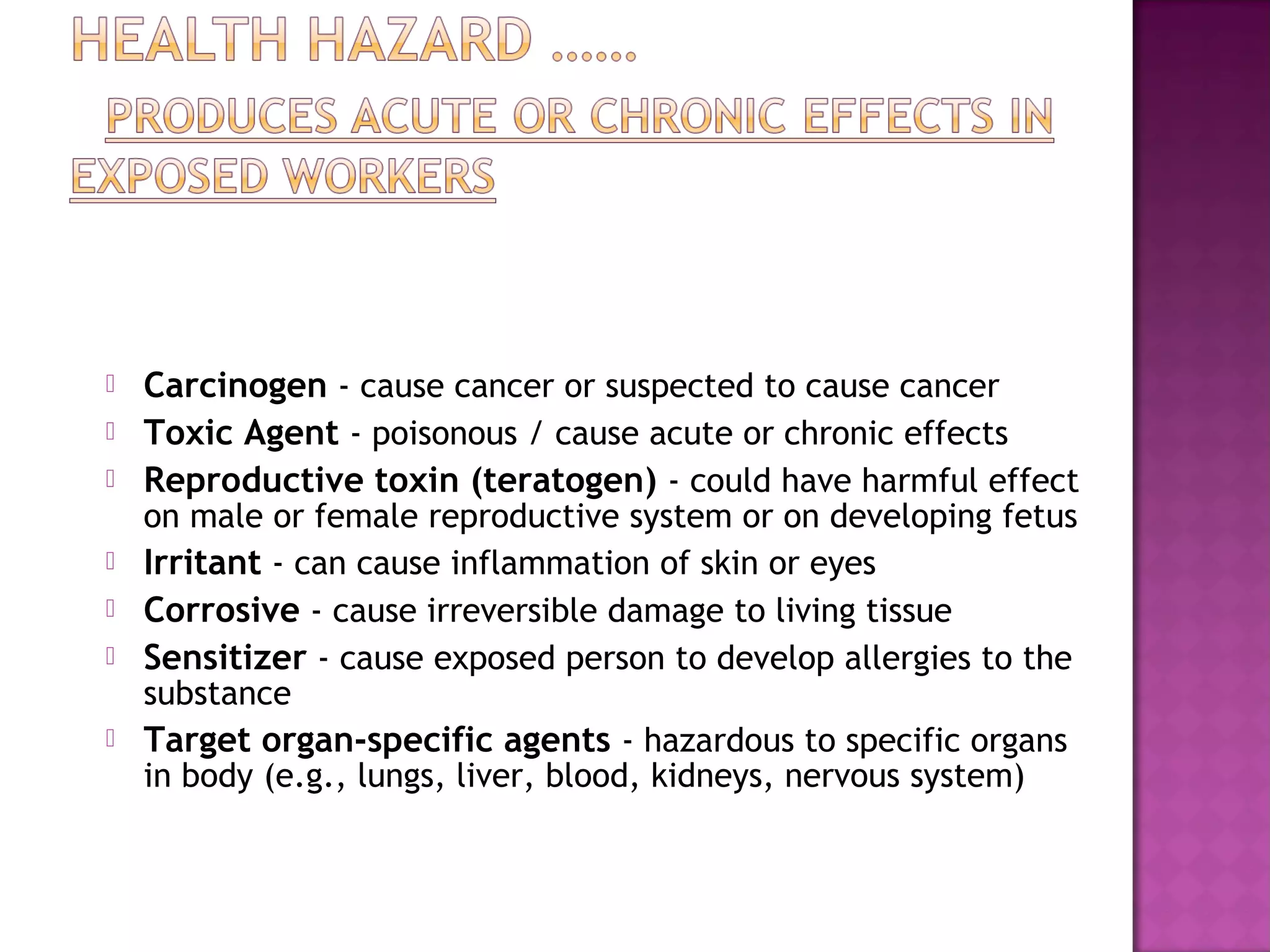

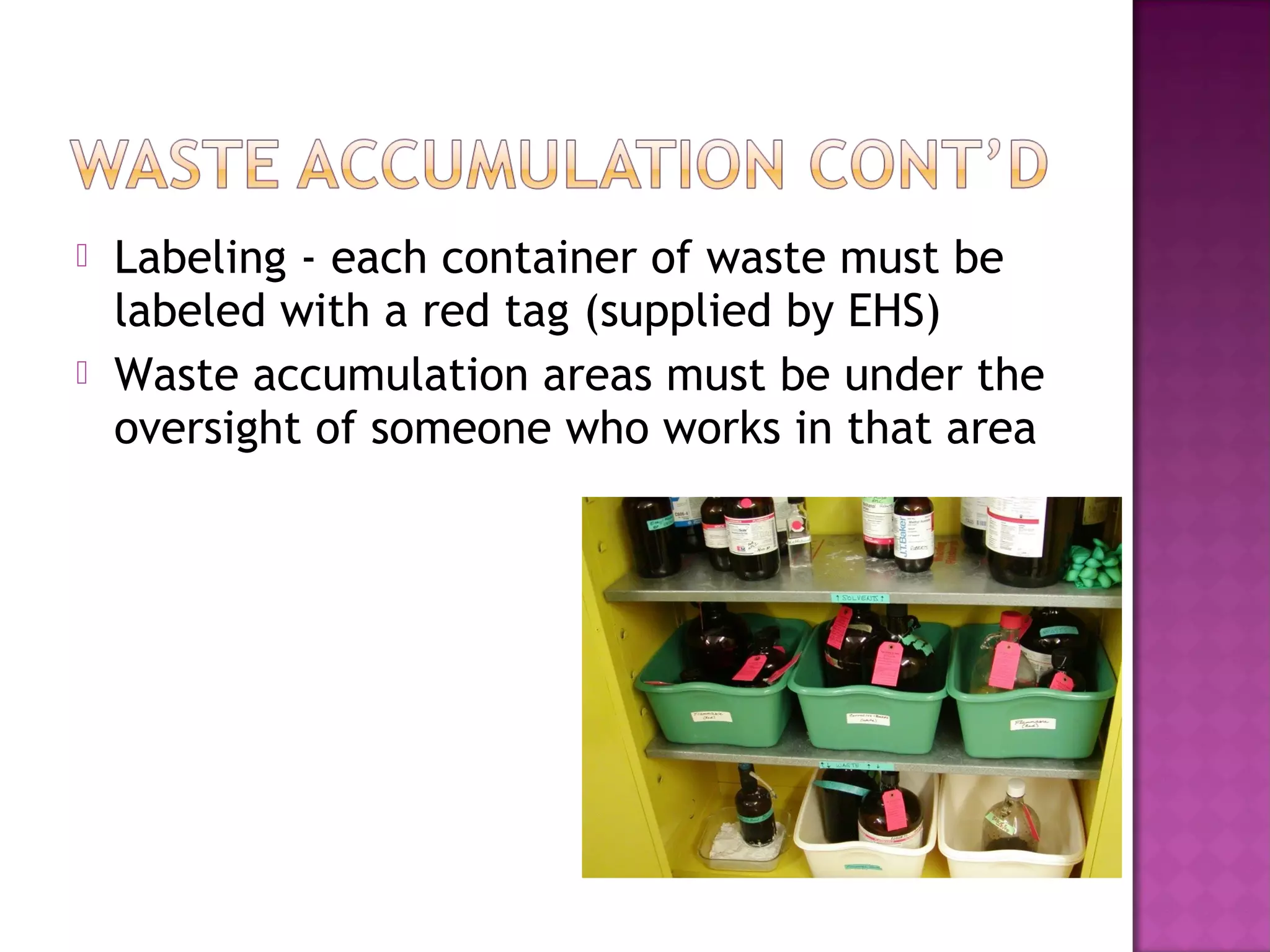

This document provides an overview of chemical safety concepts including toxicity, hazards, safe handling and storage of chemicals, disposal of chemicals, and emergency procedures. It discusses key topics such as permissible exposure limits, standard operating procedures, material safety data sheets, physical and health hazards of chemicals, routes of exposure, personal protective equipment, flammability classifications, signs and symptoms of exposure, and emergency response. The document emphasizes the importance of planning, training, labeling, using proper handling techniques and protective equipment, and knowing emergency procedures in order to safely use and dispose of chemicals.