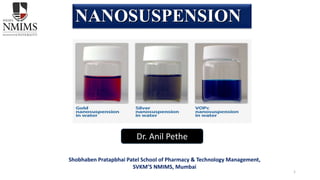

Nanosuspension

- 1. 1 NANOSUSPENSION Dr. Anil Pethe Shobhaben Pratapbhai Patel School of Pharmacy & Technology Management, SVKM’S NMIMS, Mumbai

- 2. Introduction Need of Nanosuspension Advantages of Nanosuspension Disadvantages of Nanosuspension Method Of Preparation Formulation Considerations Characterization of Nanosuspension Current Marketed Formulations Pharmaceutical Applications Conclusion References Contents 2

- 3. A pharmaceutical Nanosuspension is defined as very finely dispersed solid drug particles in an aqueous or organic vehicle for either oral and topical use or parenteral and pulmonary administration. The particle size distribution of the solid particles in nanosuspensions is usually less than one micron with an average particle size ranging between 200 and 600 nm. Nanosuspensions differ from nanoparticles. Nanoparticles are commonly polymeric colloidal carriers of drugs whereas solid lipid nanoparticles are lipidic carriers of drugs. In nanosuspension technology, the drug is maintained in the required crystalline state with reduced particle size, leading to an increased dissolution rate and therefore improved bioavailability. 3

- 4. Need of Nano suspension Poor bioavailability. Lack of dose-response proportionality . Use of harsh excipients, i.e., excessive use of co solvents and other excipients . Use of extreme basic or acidic conditions to enhance solubilisation Use for poorly water soluble as well as poorly organic soluble drugs 4

- 5. Small particle size: 300 nm to 10 microns. Low volume doses 10 – 200 mg/Ml. Safety increase because of co-solvent elimination thus increase dose. Long-term stability up to 2 years at room temperature or 5°C. Route for dosage form administration: IV injection, IM injection, ID injection, oral, respiratory and other routes. Can be used for controlled and targeted delivery of drug. Features of Nano suspension 5

- 6. Advantages of Nano suspension Can be applied for the poorly water soluble drugs. Rapid dissolution and tissue targeting can be achieved by IV route of administration. Oral administration of nanosuspensions provide rapid and improved bioavailability. Long-term physical stability due to the presence of stabilizers. Nanosuspensions can be incorporated in tablets, pellets, hydrogels. 6

- 7. Disadvantages of Nano suspension Physical stability, sedimentation and compaction can causes problems. It is bulky sufficient care must be taken during handling and transport. Uniform and accurate dose cannot be achieved unless suspension . 7

- 8. Method of Preparation of Nano suspension Precipitation Method Micro emulsion Template Media Milling (Nanocrystals) High Pressure Homogenization High Pressure Homogenization In Aq. Media (Dissocubes) High Pressure Homogenization In Non Aq. Media (Nanopure) Nanojet Technology Combination of Precipitation & HPH (Nanoedge) Supercritical Fluid Method Solvent Evaporation Method Co-grinding Method 8

- 9. The term “Bottom-up technology” means that one starts from the molecular level, and goes via molecular association to the formation of a solid particle. Classical precipitation techniques by reducing the solvent quality, for example, by pouring the solvent into a nonsolvent or changing the temperature or a combination of both. Bottom-up technology Top down technology Top-Down approaches refers to slicing or successive cutting of a bulk material to get nano sized particles. There are two types *attrition ,* milling 9

- 10. Nanosuspension Method Bottom Up Technology Precipitation Method Top down Technology Media Milling (Nanocrystals) HPH in water (Dissocubes) HPH in non- aqueous media (Nanopure) Nanojet Technology Combination of Precipitation & HPH (Nanoedge) Micro emulsion Template 10

- 11. Drug + organic solvent mixed with miscible antisolvent precipitation Advantages: Simple Process Low cost of Equipments Disadvantages: Drug needs to be soluble in at least one solvent and this solvent needs to be miscible with nonsolvent Crystal Growth Antisolvent Precipitation Method 11

- 12. This technique follows an organic solvent or mixture solvent loaded with the drug dispersed in an aqueous phase containing suitable surfactants to form an emulsion. The organic phase is then evaporated under reduced pressure to make drug particles precipitate instantaneously to form the Nanosuspension which is stabilized by surfactants. Advantages :- Use of specialized equipment is not necessary. Particle size can easily be controlled by controlling the size of the emulsion droplet. Ease of scale-up if formulation is optimized properly. Disadvantages: Drugs that are poorly soluble in both aqueous and organic media cannot be formulated by this technique. Need for ultrafiltration for purification of the drug Nanosuspension, which may render the process costly. High amount of surfactant/stabilizer is required as compared to the production techniques described earlier. Microemulsions Template 12

- 13. Apart from the use of emulsion as drug delivering vehicle they can also be used as templates to produce Nanosuspension. The use of emulsions as templates is applicable for those drugs that are soluble in either volatile organic solvent or partially water-miscile solvent. Such solvents can be used as the dispersed phase of the emulsion. An organic solvent or mixture of solvents loaded with the drug is dispersed in the aqueous phase containing suitable surfactants with stirring to form an emulsion. The obtained emulsion was further homogenized by high pressure homogenization. After homogenization cycles the emulsion was diluted with water, homogenized by homogenizer to diffuse the organic solvent and convert the droplets into solid particles. Since one particle is formed in each emulsion droplet, it is possible to control the particle size of the Nanosuspension by controlling the size of the emulsion optimizing the surfactant composition increases the intake of organic phase and ultimately the drug loading in the emulsion. Originally methanol, ethanol, ethyl acetate chloroform are used as a organic solvents. Emulsification diffusion Method 13

- 14. The nano-suspensions are prepared by using high shear media mills. The milling chamber charged with milling media, water, drug & stabilizer which are rotated at very high shear rate under controlled temperature for 2-7 days. The milling medium is composed of glass, zirconium oxide or highly cross-linked polystyrene resin. The high energy shear forces are generated as a result of impaction of milling media with the drug resulting into breaking of micro-particulate drug to nanosized particles. The major concern with this method is the residues of milling media remaining in the finished product could be problematic for administration. Media Milling 14

- 15. Advantages of media milling Applicable to the drugs that are poorly soluble in both aqueous and organic media. Very dilute as well as highly concentrated nano-suspensions can be prepared by handling 1mg/ml to 400mg/ml drug quantity. Disadvantages of media milling Nano-suspensions contaminated with materials eroded from balls may be problematic when it is used for long therapy. The media milling technique is time consuming. Some fractions of particles are in the micrometer range. Scale up is not easy due to mill size and weight. 15

- 16. It is most widely used method for preparing nanosuspensions of many poorly aqueous soluble drugs. It involves three steps. Firstly drug powders are dispersed in stabilizer solution to form pre-suspensions. Secondly the pre-suspension is homogenized in high pressure homogenizer at a low pressure for premilling. Finally homogenized at high pressure for 10 to 25 cycles until the nano-suspensions of desired size are formed. High Pressure Homogenization 16

- 17. Advantages of High Pressure Homogenizer Low risk of product contamination. Allows aseptic production of nanosuspensions for parenteral administration. Disadvantages of High Pressure Homogenizer Prerequisite of micronized drug particles. Prerequisite of suspension formation using high-speed mixers before subjecting it to homogenization. 17

- 18. Forcing the of the suspension under pressure through a narrow aperture valve. Dissocubes was developed by Muller et al in 1999. This instrument can be operated at pressure varying from 100-1500 bars (2800-21300 psi) Homogenization in Aqueous media (Dissocubes) 18

- 19. It is the most widely used method for the preparation of nanosuspensions of many poorly water soluble drugs. Dissocubes are engineered using piston-gap- type high pressure homogenizers. A commonly used homogenizer is the APV Micron LAB 40. However, other piston-gap homogenizers from Avestin and Stansted can also be used Gap. A high-pressure homogenizer consists of a high pressure plunger pump with a subsequent relief valve (homogenizing valve). The task of the plunger pump is to provide the energy level required for the relief. The relief valve consists of a fixed valve seat and an adjustable valve. These parts form an adjustable radial precision gap. The gap conditions, the resistance and thus the homogenizing pressure vary as a function of the force acting on the valve 19

- 20. Principle of Dissocubes In piston gap homogenizer particle size reduction is based on the cavitations principle. Particles are also reduced due to high shear forces and the collision of the particles against each other. The dispersion contained in 3 cm diameter cylinder; suddenly passes through a very narrow gap of 25 μm. According to Bernoulli’s Law the flow volume of liquid in a closed system per cross section is constant. The reduction in diameter from 3 cm to 25 μm leads to increase in dynamic pressure and decrease of static pressure below the boiling point of water at room temperature. Due to this water starts boiling at room temperature and forms gas bubbles, which implode when the suspension leaves the gap (called cavitations) and normal air pressure, are reached. The size of the drug nanocrystals that can be achieved mainly depends on factors like temperature, number of homogenization cycles, and power density of homogenizer and homogenization pressure 20

- 21. The drug suspensions in the non- aqueous media were homogenized at 0º C or even below the freezing point and hence are called Deepfreeze homogenization Advantages : Evaporation is faster and under milder conditions. This is useful for temperature sensitive drugs. Homogenization in Non-Aqueous media (Nanopure) 21

- 22. This technique, called opposite stream or nanojet technology, uses a chamber where a stream of suspension is divided into two or more parts, which colloid with each other at high pressure. The high shear force produced during the process results in particle size reduction. Equipment using this principle includes the M110L and M110S microfluidizers (Microfluidics). Disadvantage: obtained product contains larger particles of nanoemulsion. Nanojet Technology 22

- 23. It is a combined method of Precipitation and Homogenization. The drug is dissolved in an organic solvent and this solution is mixed with a miscible antisolvent for precipitation. The precipitated particle suspension is homogenized. Advantage: Drawback of the precipitation technique, such as crystal growth and long-term stability, can be resolved Nanoedge Technology 23

- 24. The precipitated drug nanoparticles have tendency to continue crystal growth to the size of microcrystals. They need to be processed with high-energy forces (Homogenisation). The are in completely amorphous, partially amorphous or completely crystalline which create problems in long term stability as well as in bioavailability, so the precipitated particle suspension is subsequently homogenized which preserve the particle size obtained after the precipitation step. Nanoedge Technology 24

- 25. Supercritical fluid technology can be used to produce nanoparticles from drug solutions. The various methods attempted are rapid expansion of supercritical solution process (RESS), supercritical anti-solvent process and precipitation with compressed anti-solvent process (PCA). The RESS involves expansion of the drug solution in supercritical fluid through a nozzle, which leads to loss of solvent power of the supercritical fluid resulting in precipitation of the drug as fine particles. Young et al prepared cyclosporine nanoparticles in the size range of 400-700 nm using this process. In the PCA method, the drug solution is atomized into a chamber containing compressed CO2. As the solvent is removed, the solution gets supersaturated and thus precipitates as fine crystals. The supercritical anti- solvent process uses a supercritical fluid in which a drug is poorly soluble and a solvent for the drug that is also miscible with the supercritical fluid. The drug solution is injected into the supercritical fluid and the solvent gets extracted by the supercritical fluid and the drug solution gets supersaturated. The drug is then precipitated as fine crystals. Supercritical Fluid Method 25

- 26. In this process micronization of drug particles within narrow range of particle size is carried out. It forms particles size range 5-2000 nm in diameter. Disadvantage: Surfactants in Supercritical CO2 and high pressure requires 18 Supercritical Fluid Method 26

- 27. Drug + Polymer in organic solvent Dropped by syringe in dist. water containing surfactant Homogenized using magnetic stirrer Solvent removal by air drying Solvent Evaporation Method 27

- 28. Nanosuspension is also prepared by dry milling techniques. In this method, dry grinding of poorly water soluble drugs with soluble polymers and copolymers are dispersing in liquid medium. Co-grinding Method 28

- 29. Stabilizer:- Lecithine, PVPK 30, PVA, SLS, Poloxamers, Polysorbates, Organic solvents:- water miscible solvents:- ethanol & isopropanol Partially water miscible :- ethyl acetate, ethyl formate, butyl lactate, triacetin, propylene carbonate & benzyl alcohol Surfactants:- Tweens and Spans - widely used surfactants Co-surfactants:- Transcutol, glycofurol, ethanol ,iso-propanol , bile salts Dipotassium glycerrhizinate etc. Other additives:- Buffers (acetate, phosphate) cryprotectants (sucrose as sugar) 22 Formulation of Nano suspension 29

- 30. In vitro Evaluations: Mean particle size and size distribution: •The mean particle size distribution and its ranges named Polydispersity index (PI) is measured by Laser Diffractometry (LD), Photon Correlation Spectroscopy and Coulter Counter method. PI gives the physical stability. A PI value 0.1 – 0.25 shows narrow size distribution. •LD can detect and quantify drug microparticles and also gives volume size distribution. •The Coulter counter gives the absolute no. of particles per volume for the different size classes. Drug Entrapment Efficiency: Initial Drug – Free Drug Entrapment Efficiency (%) = × 100 Initial Drug Transmission Electron Microscopy (TEM): For the morphological evaluation of nanoparticles. Fourier Transform Infrared Spectroscopy (FTIR): Characterization of Nano suspension 30

- 31. X-ray Powder Diffraction (XPRD): Differential Scanning Calorimetry (DSC): Particle charge (Zeta Potential): Particle charge determines the stability of nanosuspension. For electrostatically stabilized nanosuspension a minimum zeta potential of ±30 mV In Vitro Drug Release: Saturation Solubility: Stability Study: In Vivo Evaluation: Characterization of Nano suspension 31

- 32. Stability of Nano suspension with relation to Zeta Potential 32

- 33. Bioavailability enhancement Nanosuspensions resolve the problem of poor bioavailability by solving the twin problems of poor solubility and poor permeability across the membrane. Oral administration of the gonadotrophin inhibitor Danazol as nanosuspension leads to an absolute bioavailability of 82.3 and the conventional dispersion (Danocrine) only to 5.2 Bioavailability of poorly soluble oleanolic acid, a hepatoprotective agent, was improved using a nanosuspension . Oral applications 33

- 34. Since the drug particles are directly nanosized, it becomes easy to process almost all drugs for parenteral administration. Moreover, the absence of any harsh solvents/co-solvents and/or any potentially toxic ingredient in nanosuspensions enables them to bypass the limitations of parenteral administration attributed to conventional formulations strategies. Hence, nanosuspensions enable significant improvement in the parenterally tolerable dose of the drug, leading to a reduction in the cost of the therapy and also improved therapeutic performance Example:The maximum tolerable dose of paclitaxel nanosuspension was found to be three times higher than the currently marketed Taxol, which uses Cremophore EL and ethanol to solubilize the drug. Paclitaxel nanosuspensions at doses of 90 and 100mg/kg showed no cases of death , whereas Taxol at a concentration of 30mg/ kg showed a 22% death rate. Parenteral applications 34

- 35. Intravenous administration: IV administration results in several advantages, such as administration of poorly soluble drugs without using a higher concentration of toxic cosolvents, improving the therapeutic effect of the drug available as conventional oral formulations and targeting the drug to macrophages and the pathogenic microorganisms residing in the macrophages. Injectable nanosuspensions of poorly soluble drug tarazepide have been prepared to overcome the limited success achieved using conventional solubilization techniques, such as use of surfactants, cyclodextrins, etc., to improve bioavailability. 35

- 36. Nanosuspensions, by their inherent ability to improve the saturation solubility of the drug, represent an ideal approach for ocular delivery of hydrophobic drugs. Moreover, the nanoparticulate nature of the drug allows its prolonged residence in the cul-de-sac, giving sustained release of the drug. To achieve sustained release of the drug for a stipulated time period, nanosuspensions can be incorporated in a suitable hydrogel base or mucoadhesive base or even in ocular inserts. Ocular applications 36

- 37. The nanoparticulate nature of the drug allows the rapid diffusion and dissolution of the drug at the site of action. At the same time, the increased adhesiveness of the drug to mucosal surfaces offers a prolonged residence time for the drug at the absorption site. This ability of nanosuspensions to offer quick onset of action initially and then controlled release of the active moiety is highly beneficial and is required by most pulmonary diseases e.g.: Budesonide, a poorly water-soluble corticosteroid, has been successfully formulated as a nanosuspension for pulmonary delivery 28 Pulmonary applications 37

- 38. Nanosuspensions can also be used for targeting as their surface properties and changing of the stabilizer can easily alter the in vivo behavior. The drug will be up taken by the mononuclear phagocytic system to allow regional-specific delivery. This can be used for targeting anti-mycobacterial, fungal or leishmanial drugs to the macrophages if the infectious pathogen is persisting intracellularly. Kayser formulated a nanosuspension of Aphidicolin to improve drug targeting against leishmania-infected macrophages. Drug Targetting 38