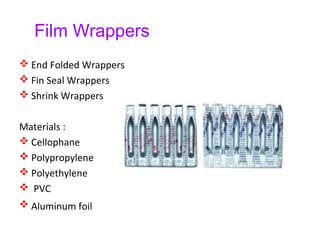

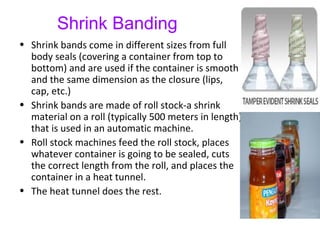

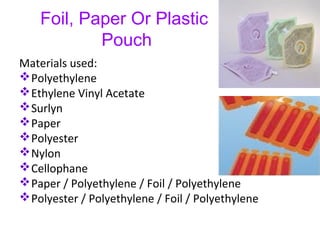

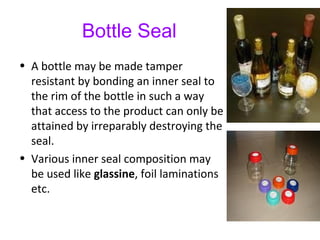

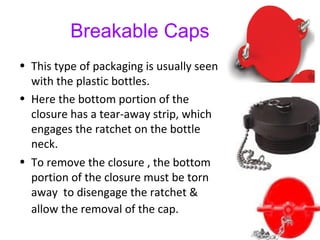

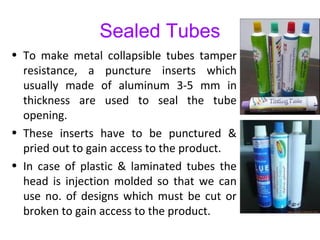

This document discusses various packaging solutions to prevent pilferage and tampering of pharmaceutical products. It describes common types of pilferproof and tamper-evident packaging such as blister packs, shrink wrapping, pouches, bottle seals, tape seals, and breakable caps. The document also discusses considerations for making packaging pilfer-resistant and tamper-evident, as well as historical examples like the 1982 Chicago Tylenol murders that led to new anti-tampering laws.