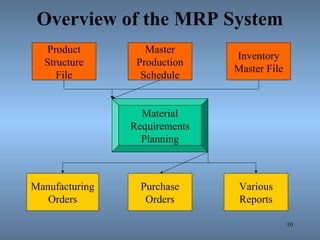

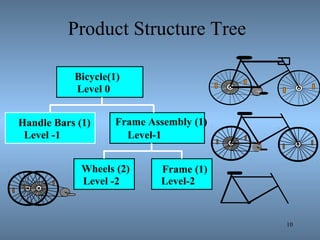

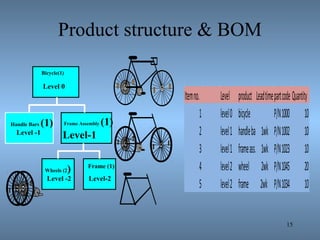

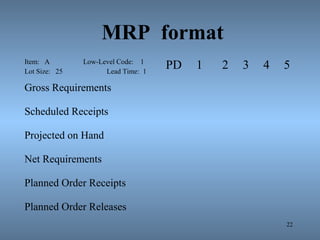

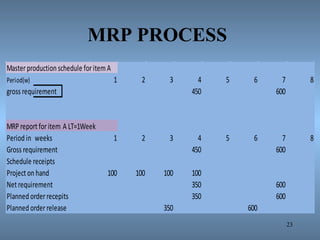

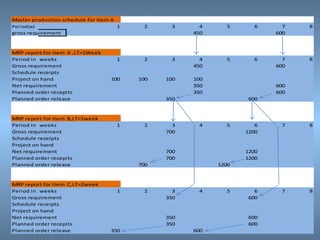

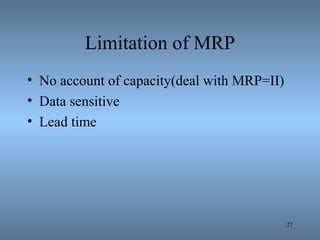

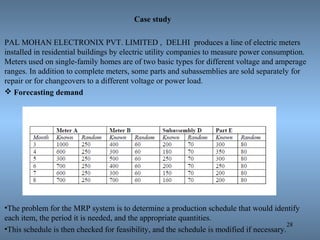

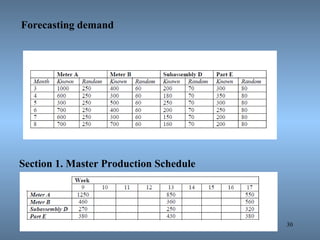

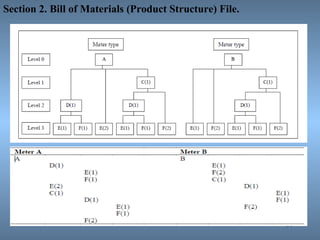

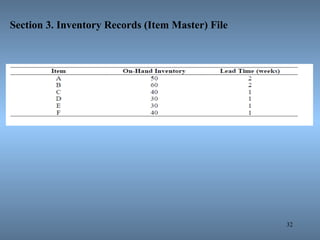

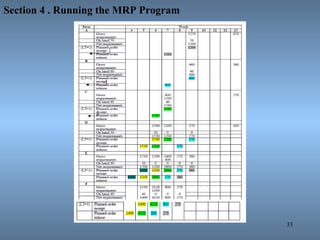

MRP (Material Requirements Planning) is a system used to plan for materials needs based on production schedules and inventory levels. It was developed in the 1960s and helps ensure availability of materials for production and delivery to customers while maintaining low inventory levels. The MRP process involves using a master production schedule, bill of materials, and inventory records to generate reports showing what materials are needed, how many, and when to support production needs. It aims to balance optimizing service levels and minimizing costs and capital tied up in inventory.