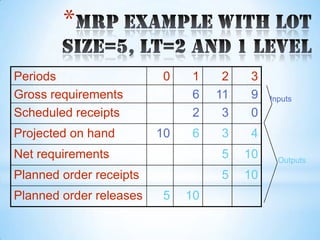

The document discusses material requirements planning (MRP), which is a production planning and inventory control system used to manage manufacturing processes. MRP determines item-by-item what needs to be produced and purchased, when, and in what quantities based on inputs like the master production schedule, bill of materials, and available inventory and capacities. The goal of MRP is to simultaneously meet objectives like ensuring availability of materials for production, maintaining low inventory levels, and planning manufacturing activities.