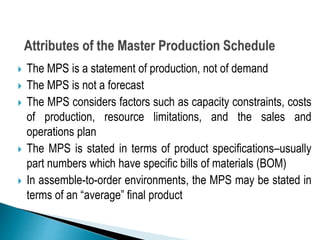

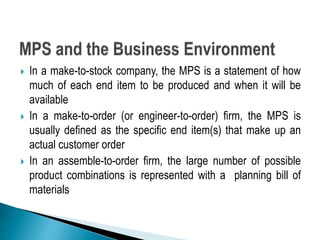

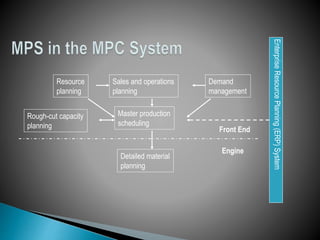

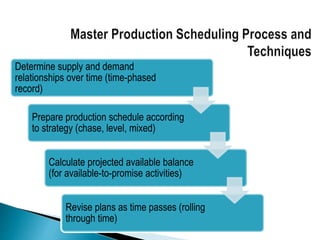

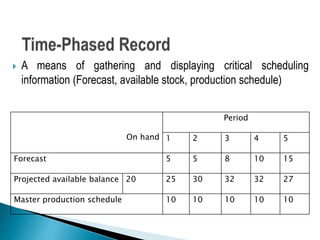

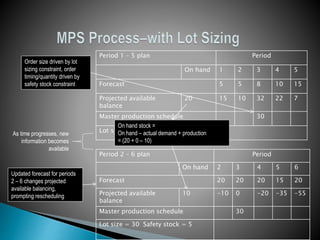

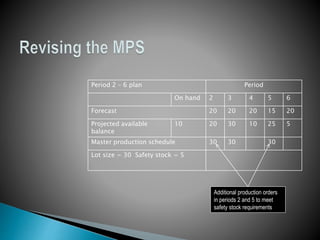

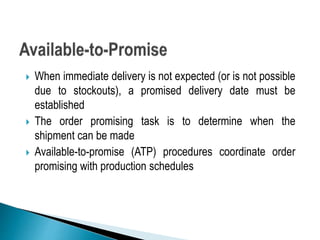

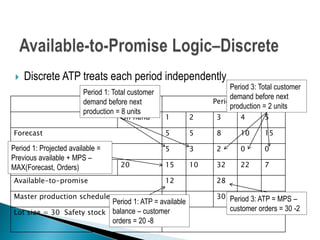

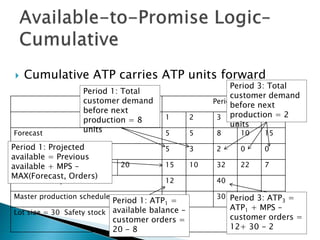

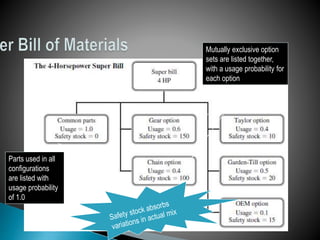

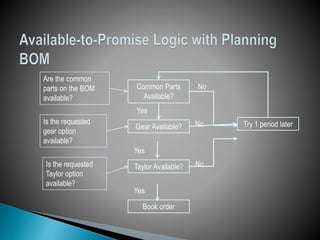

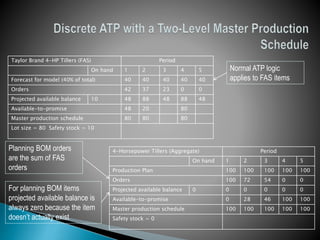

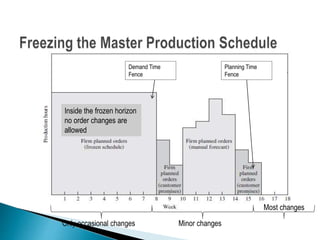

The document discusses the master production schedule (MPS), which translates the sales and operations plan into a statement of the specific products and quantities to be manufactured over time. It considers factors like capacity, costs, and resources to determine when products will be available. The MPS forms the basis for production activities and trade-offs between production and sales. It aims to provide stability while allowing for changes as more information becomes available.