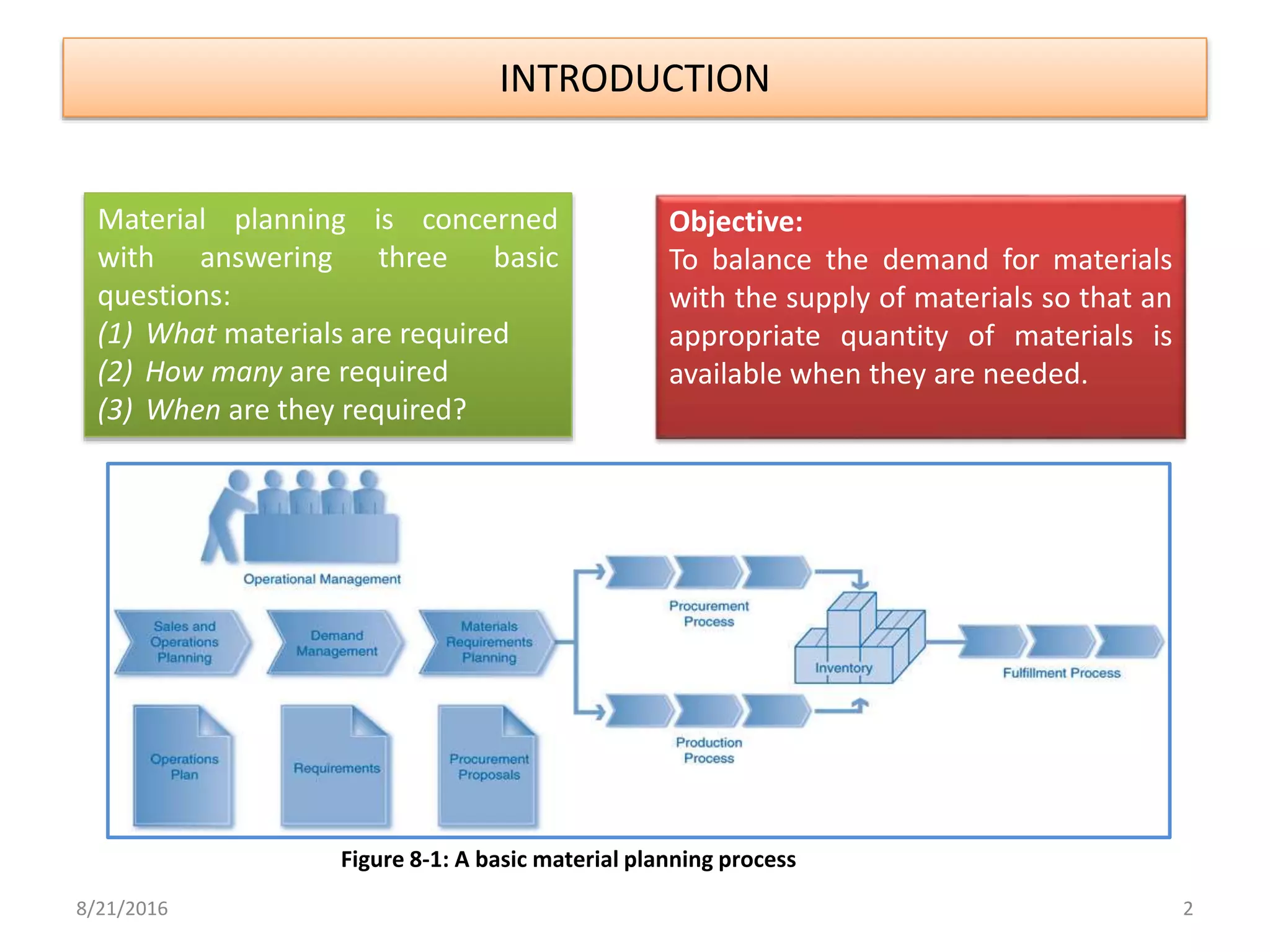

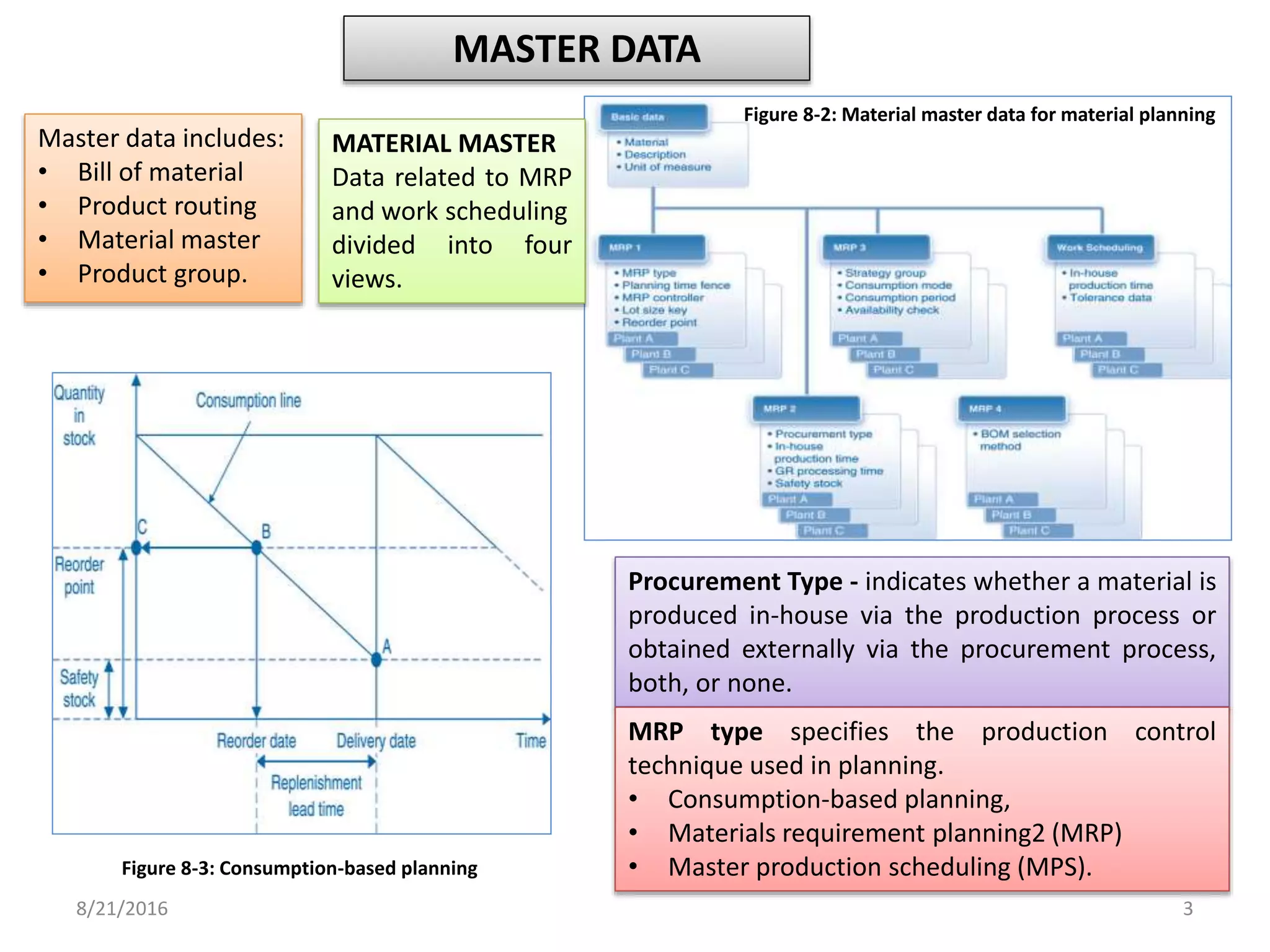

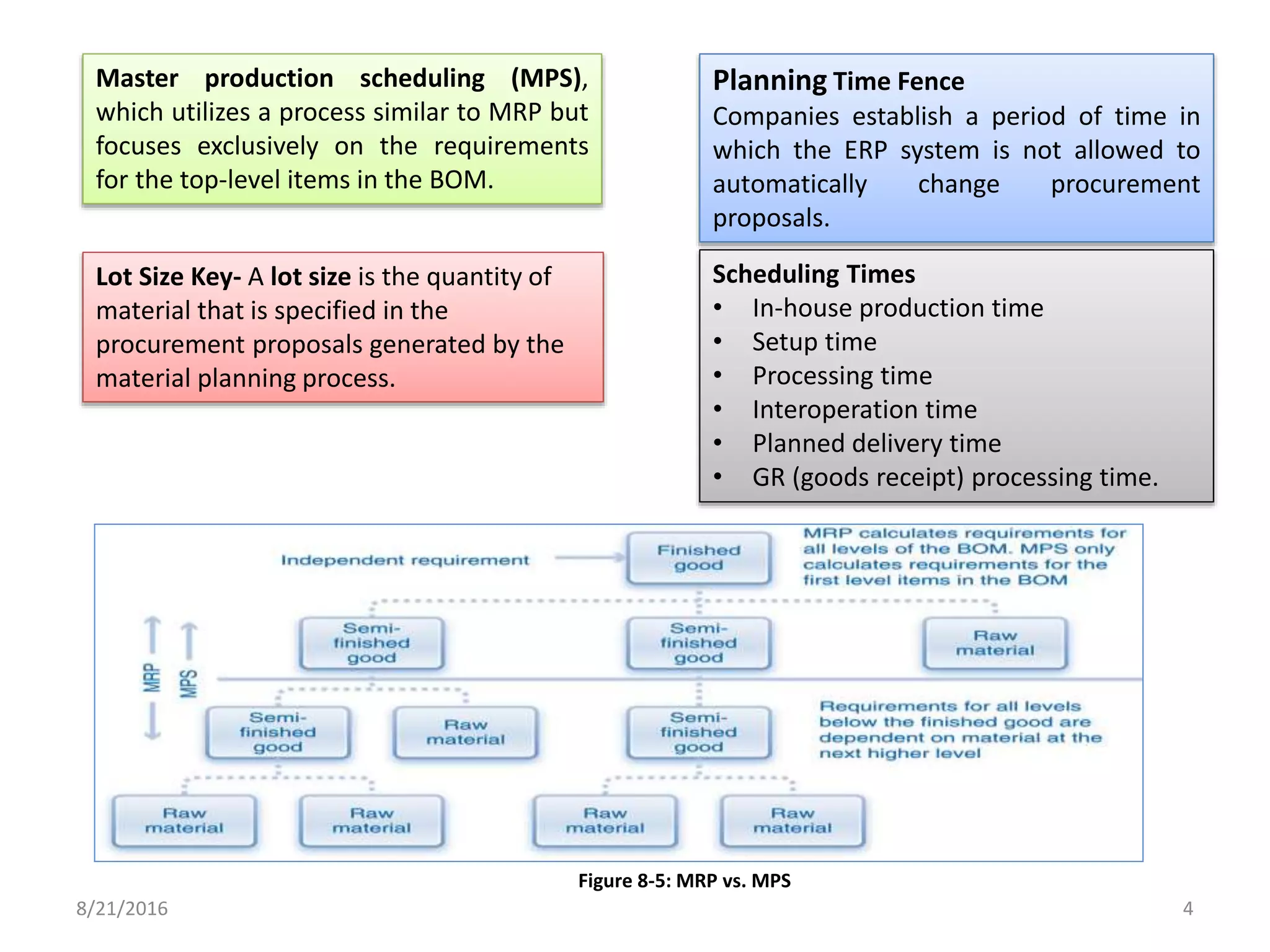

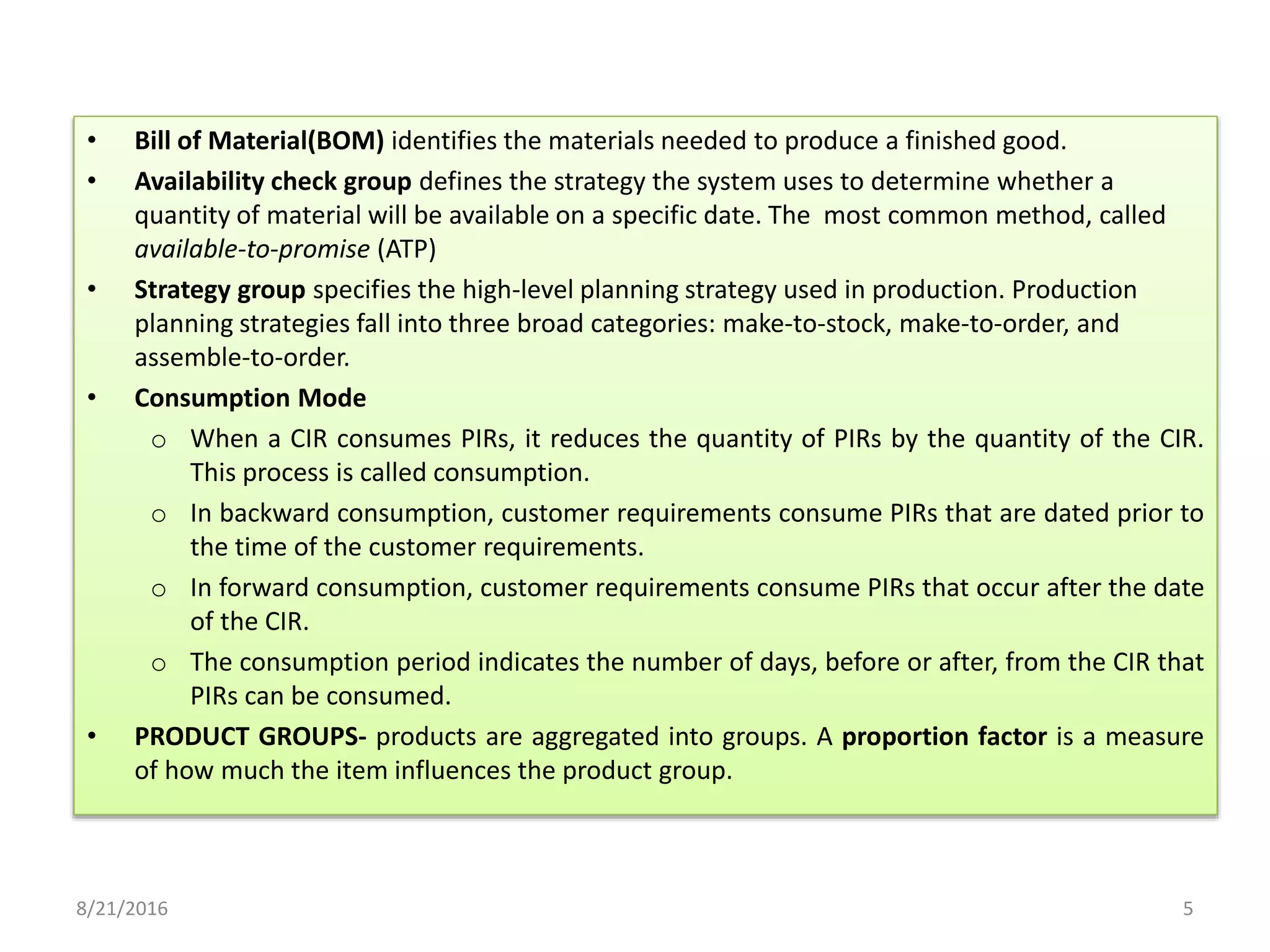

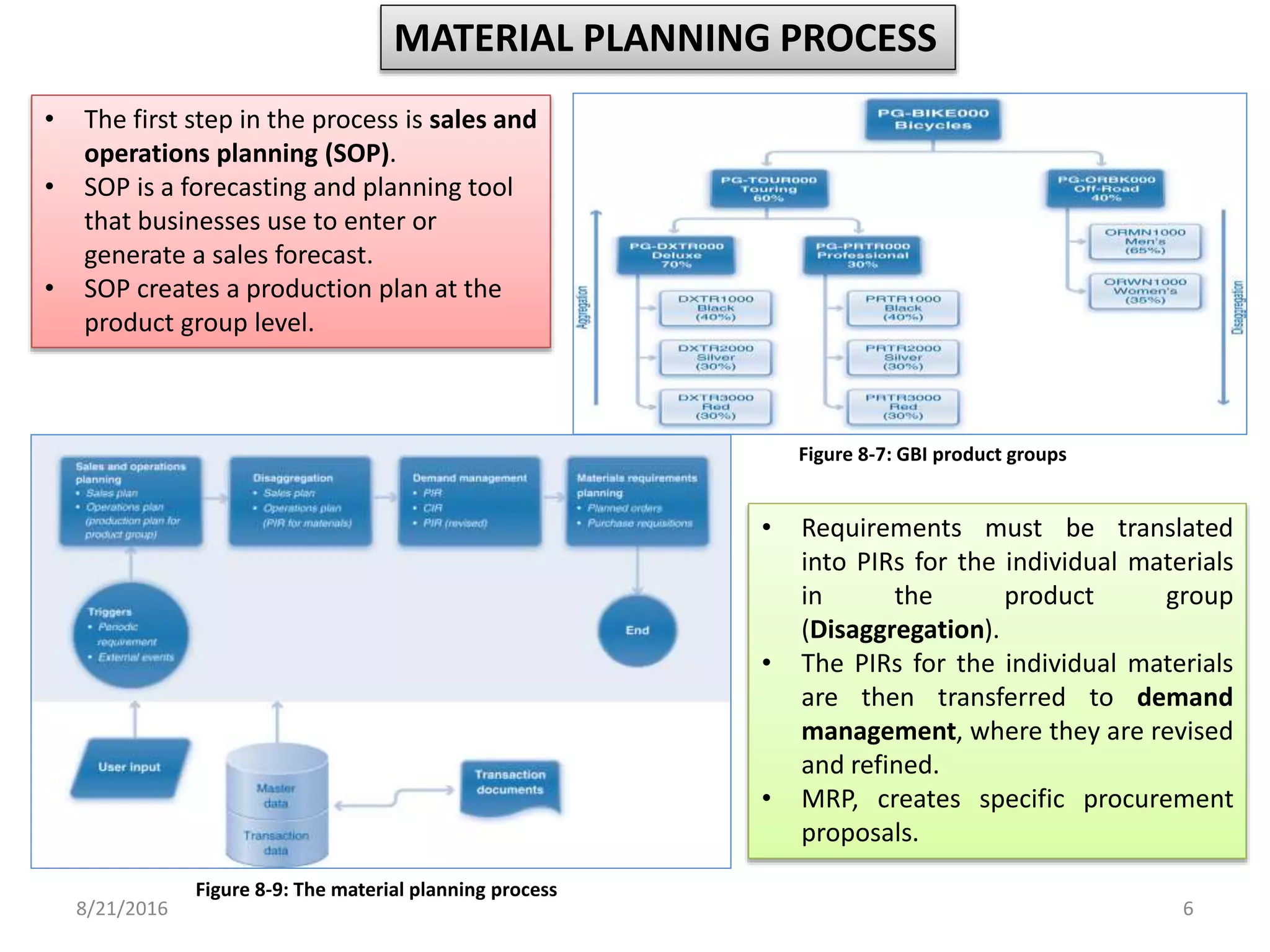

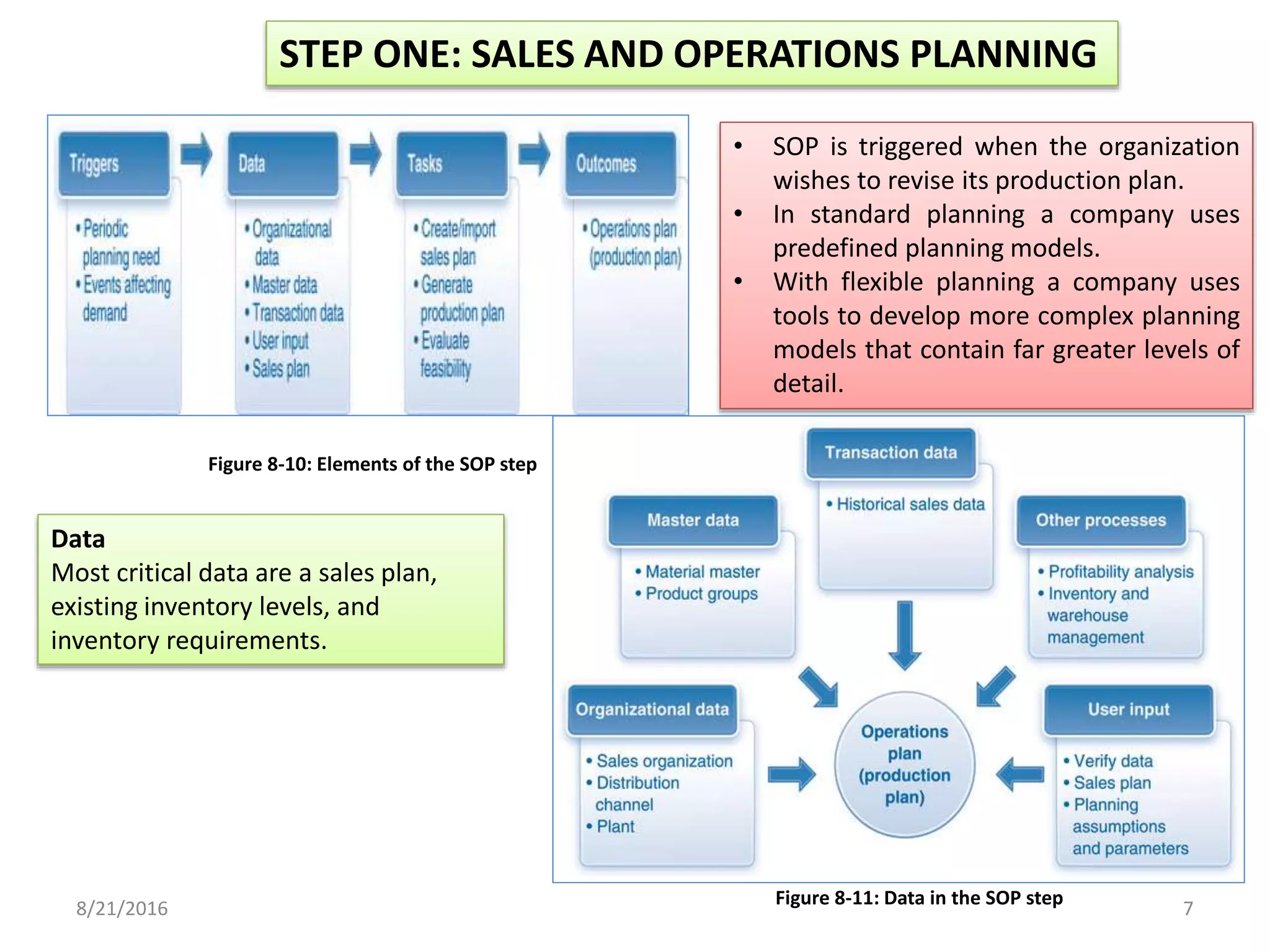

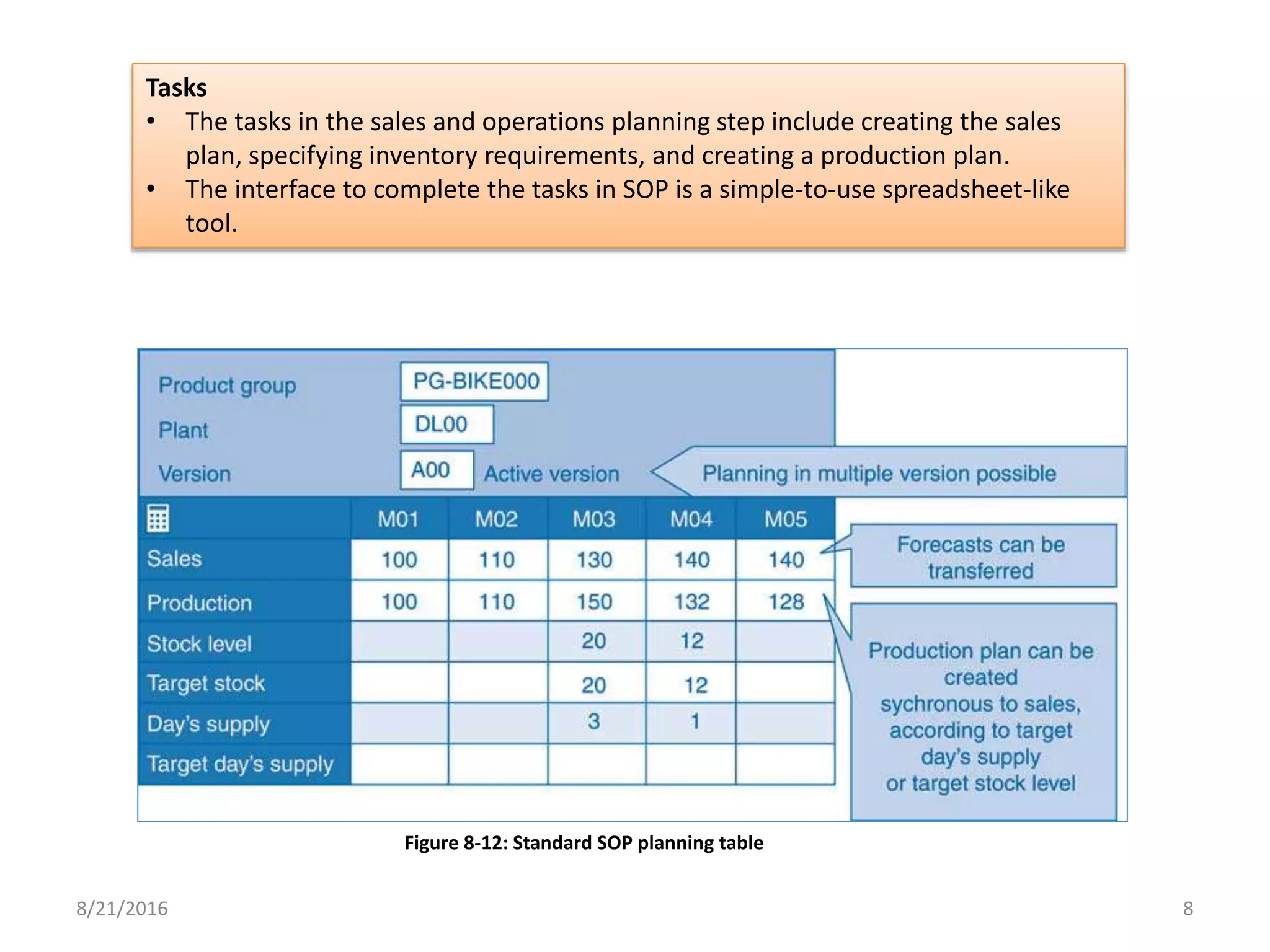

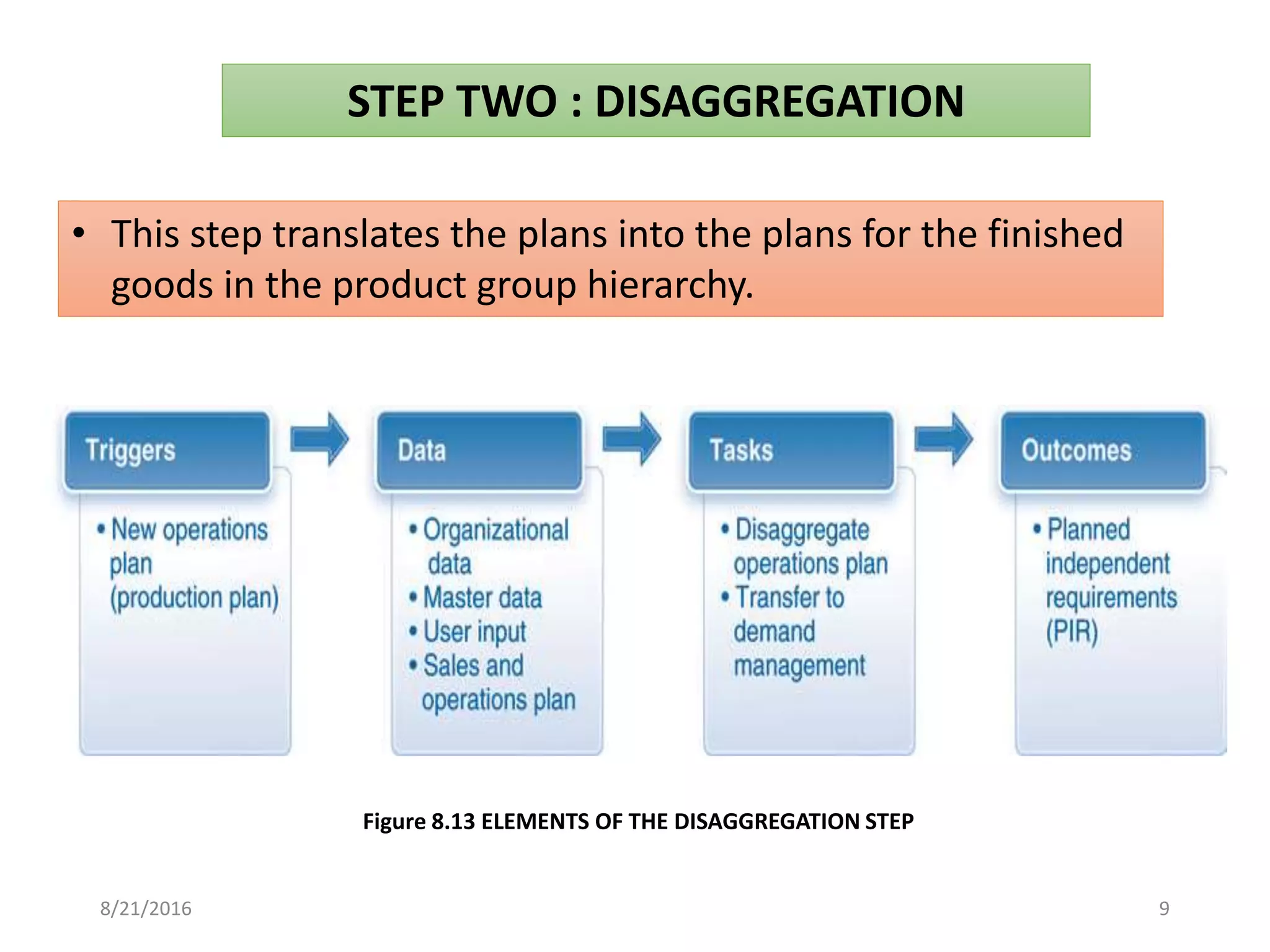

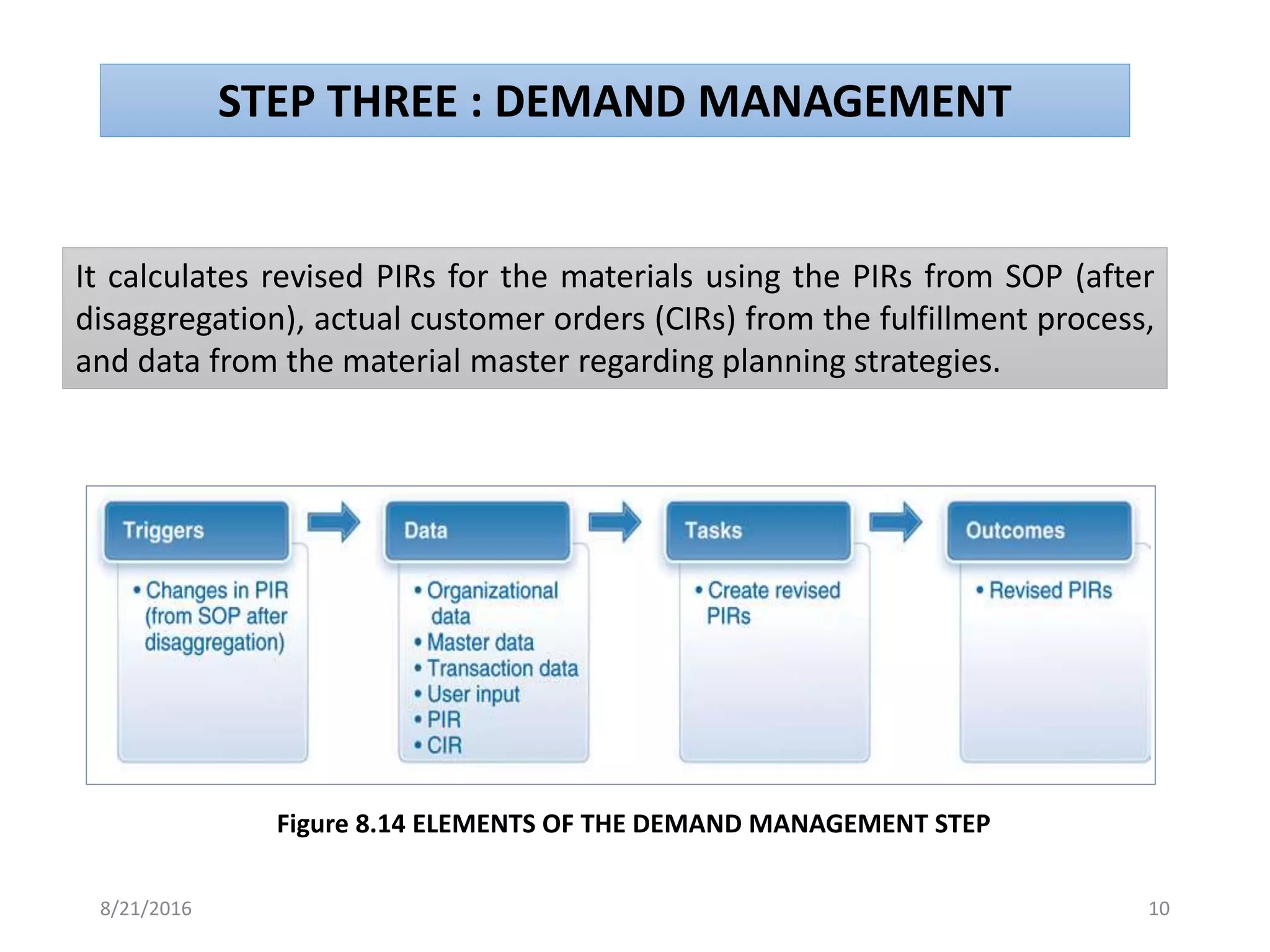

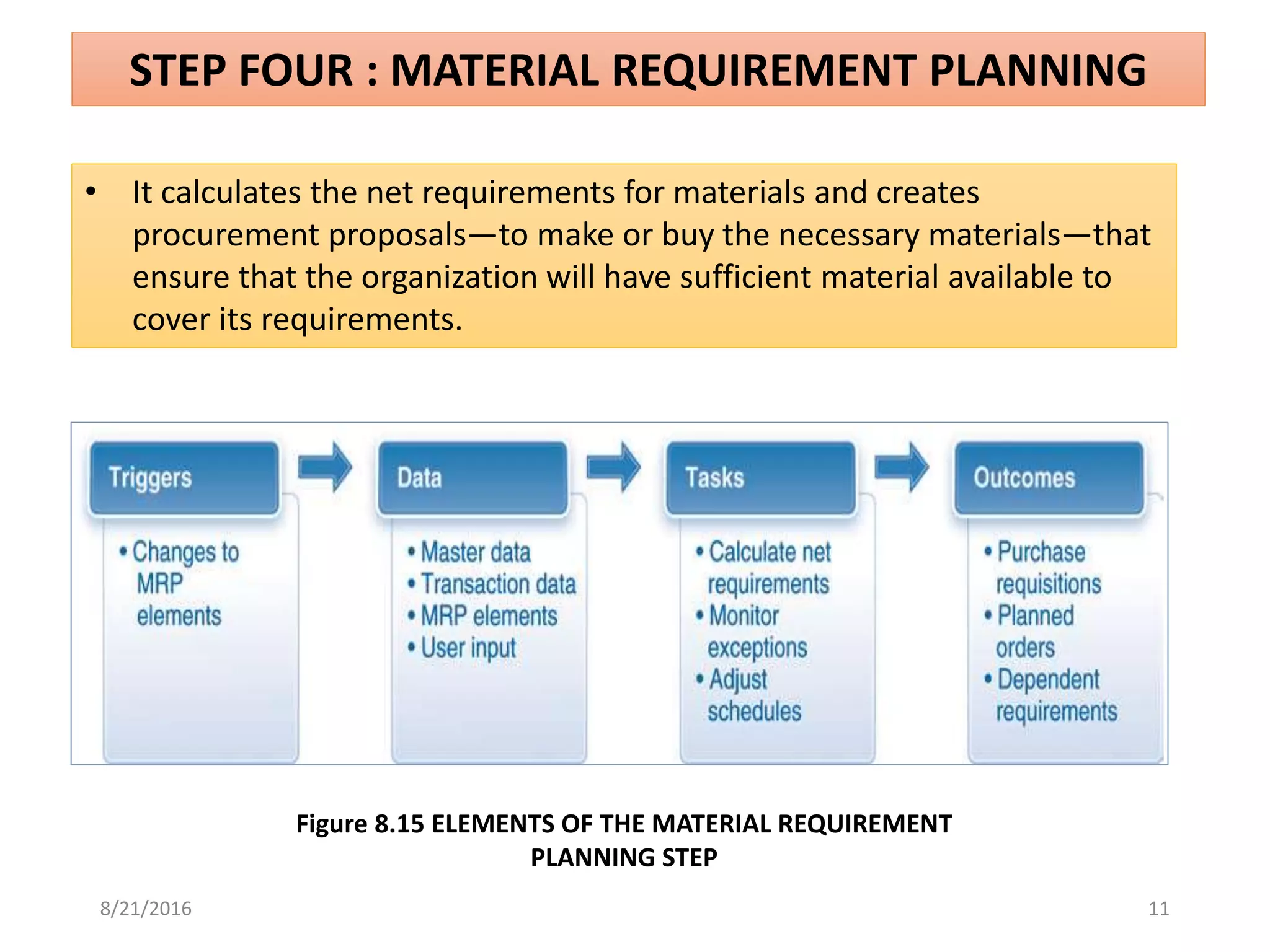

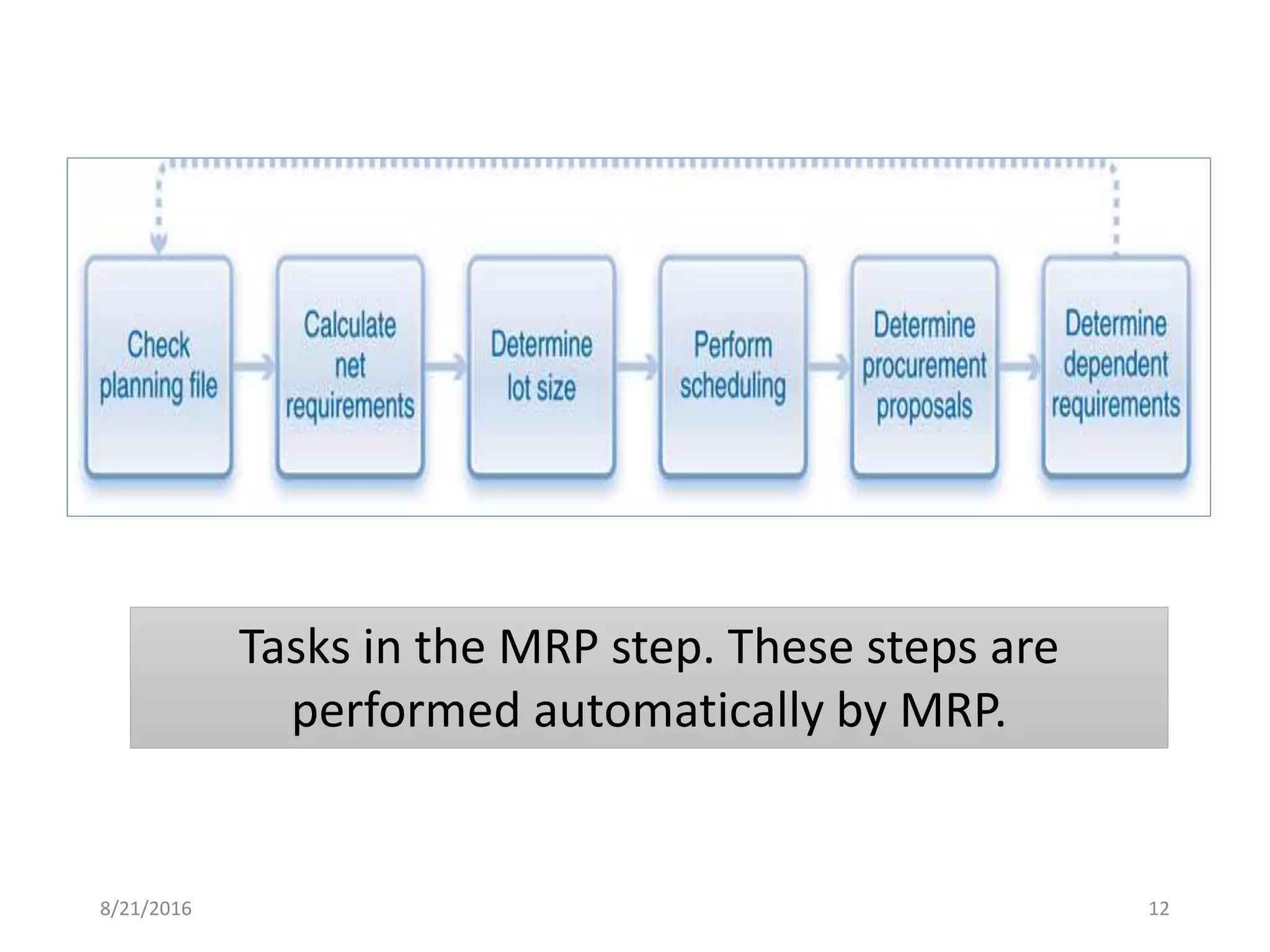

The document describes the integrated material planning process within ERP systems. It involves four main steps: (1) sales and operations planning (SOP) where a production plan is created at the product group level, (2) disaggregation where product group requirements are translated to individual material requirements, (3) demand management where customer orders are incorporated to revise material requirements, and (4) material requirements planning (MRP) where procurement proposals are created to ensure sufficient material availability. Reporting tools provide information on the planning situation including a stock/requirements list, MRP list, and planning result report. The overall goal of material planning is to balance supply and demand of materials so the right quantity is available when needed.