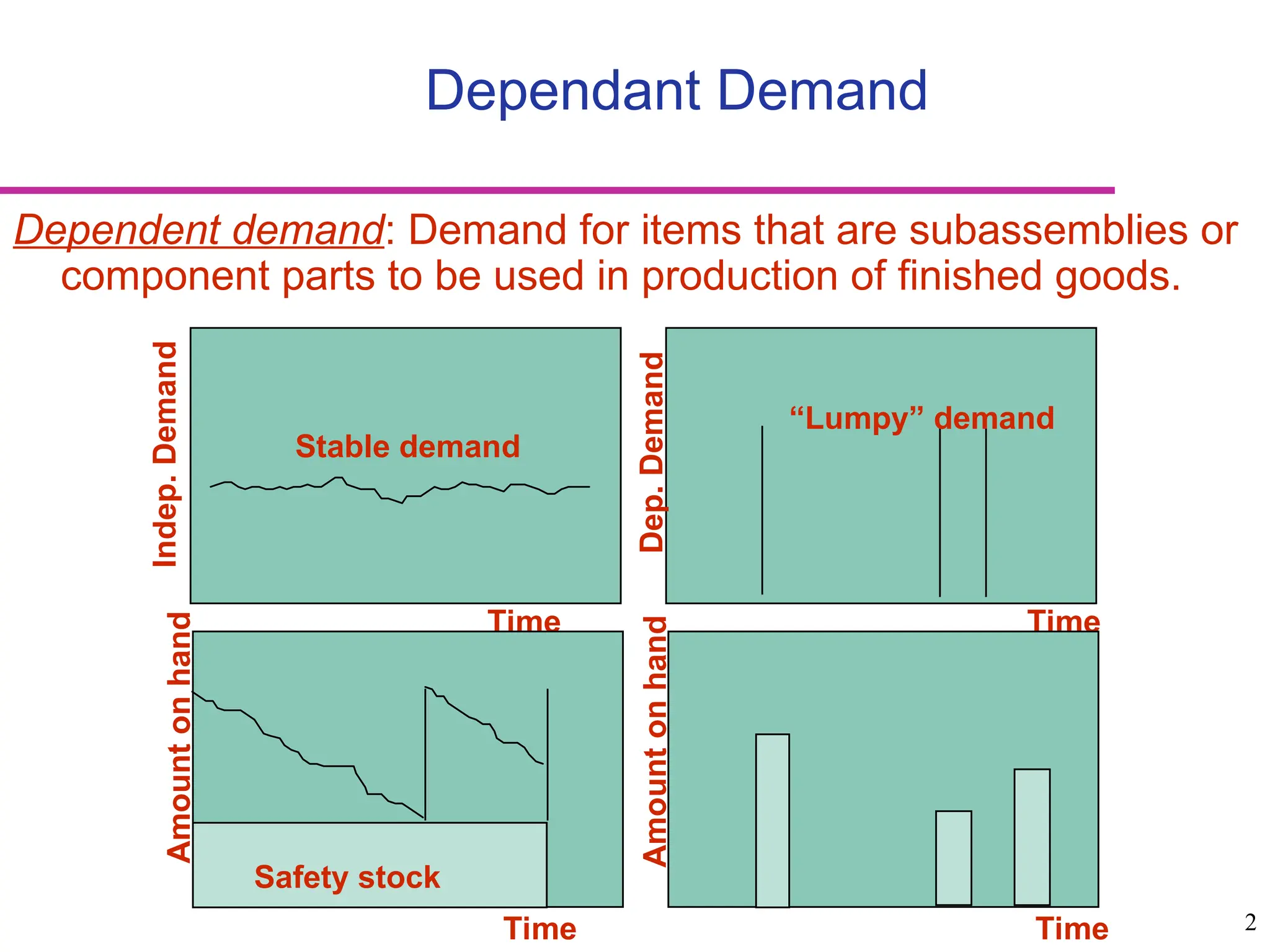

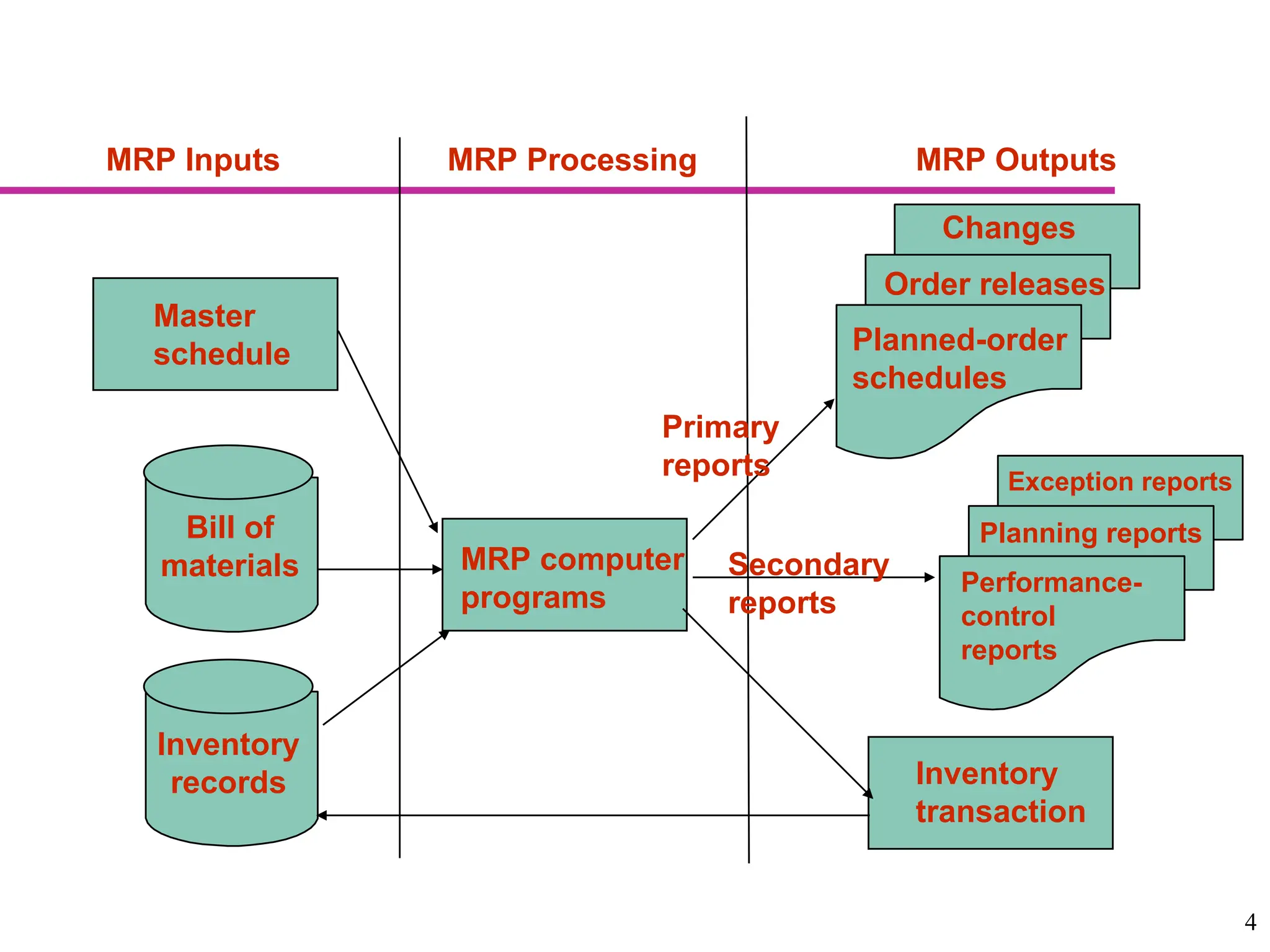

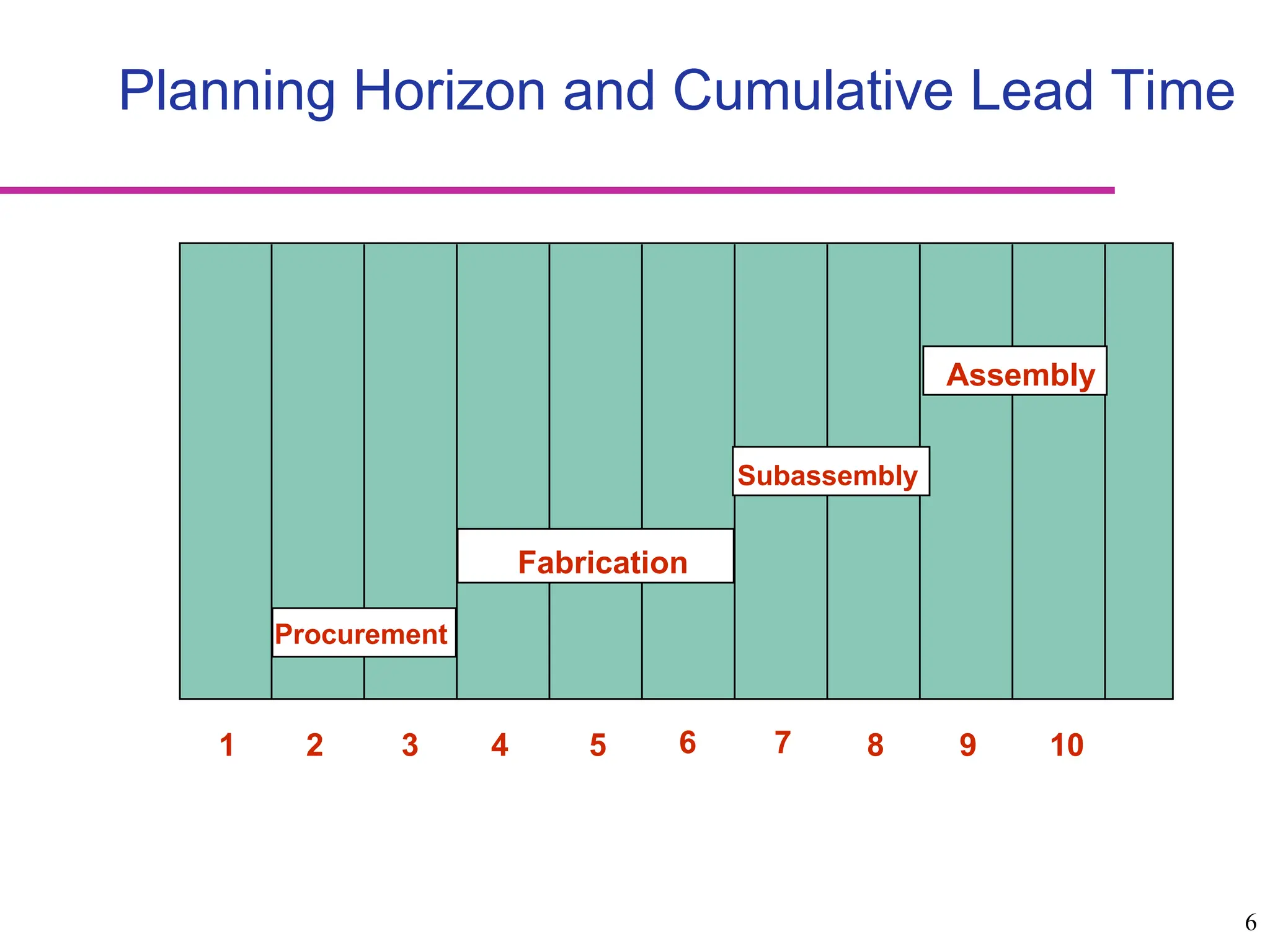

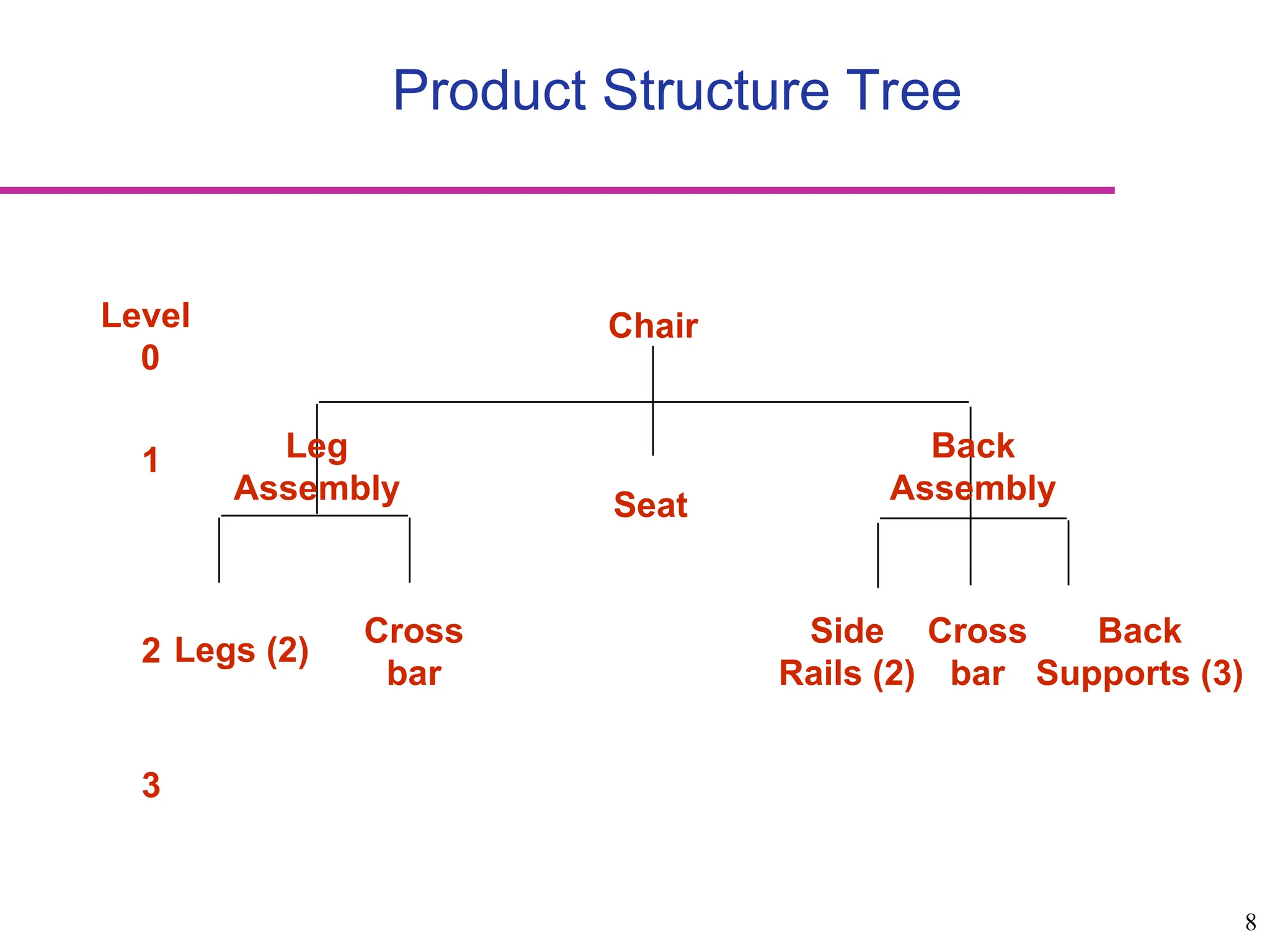

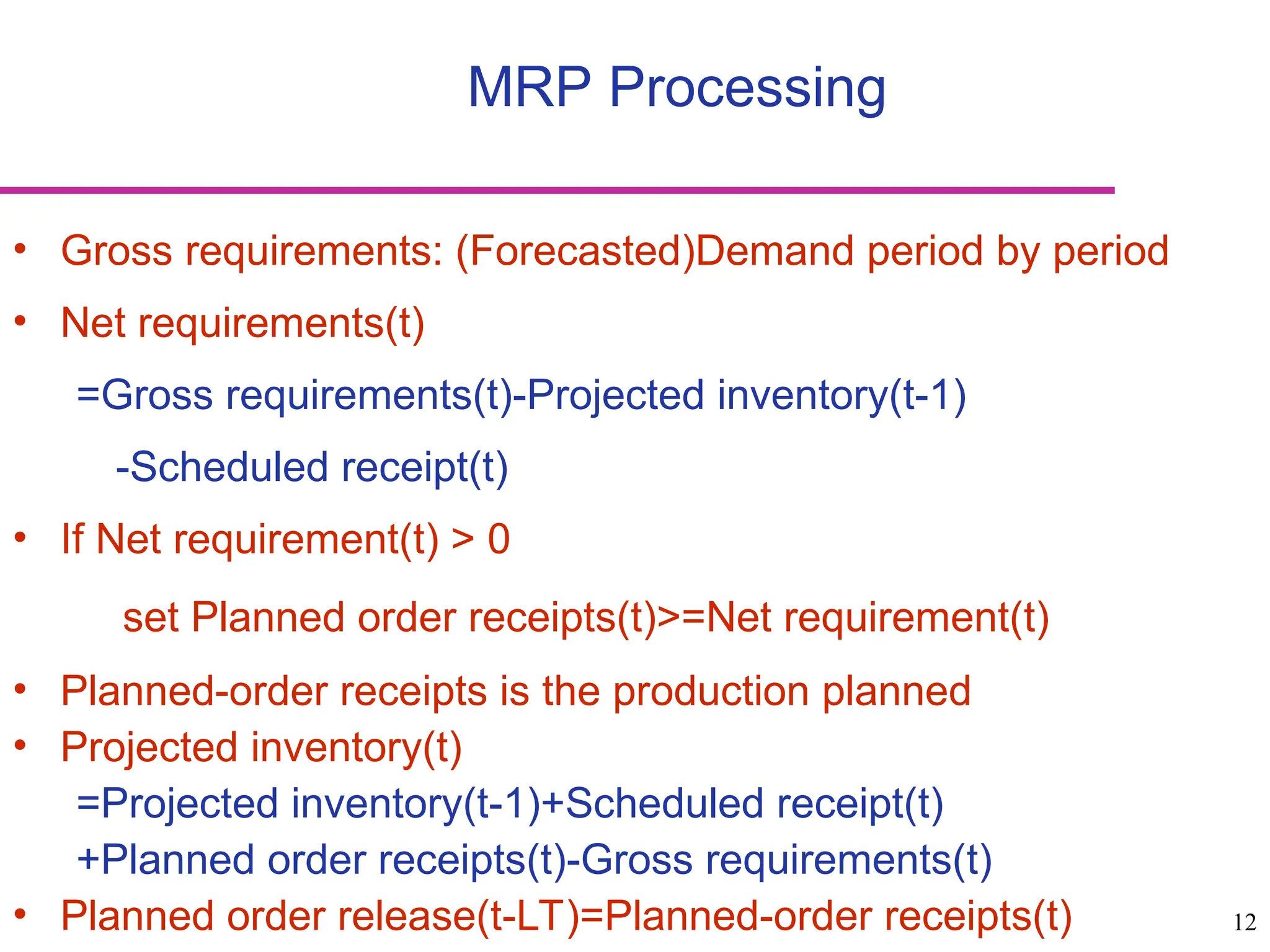

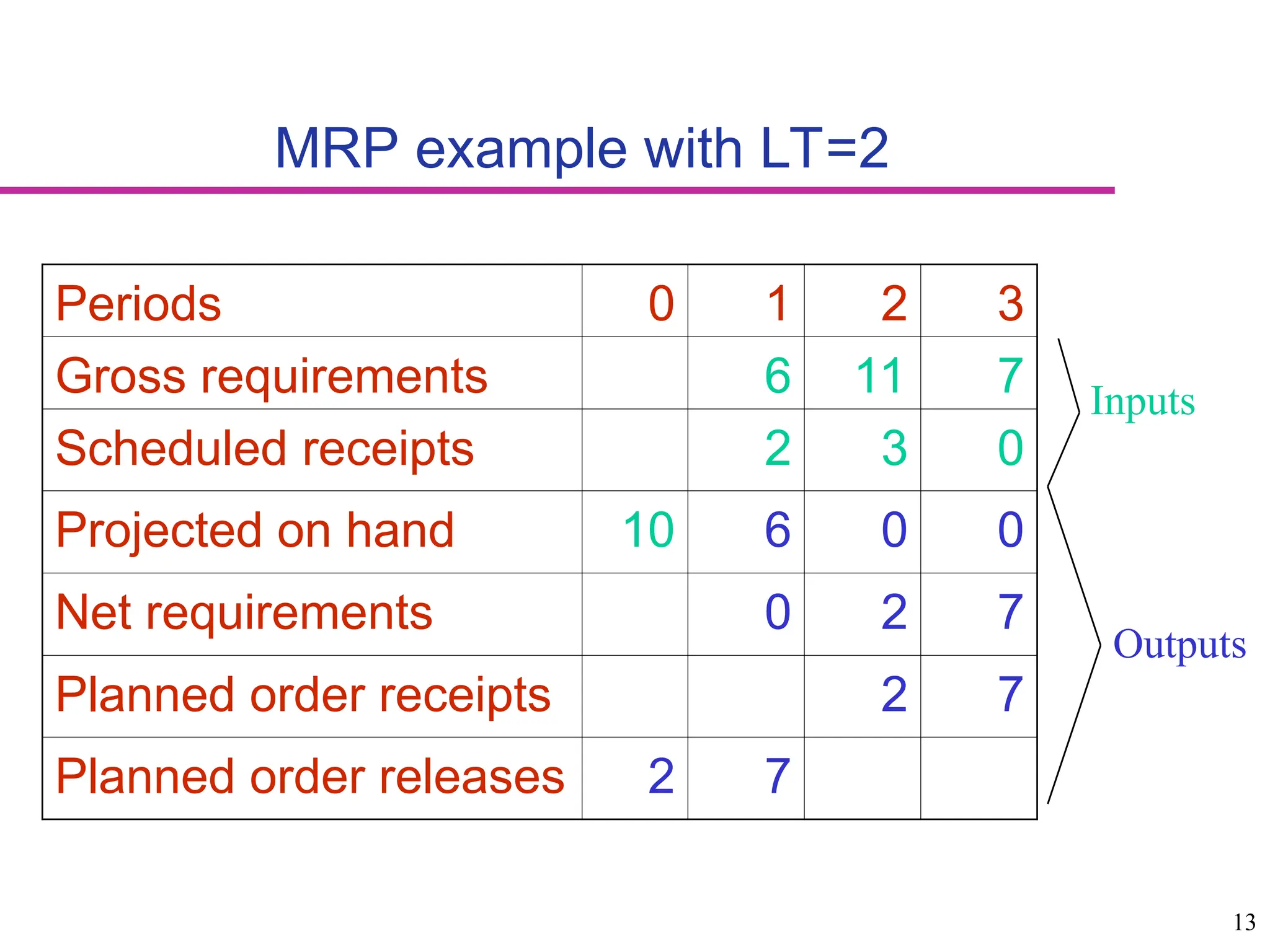

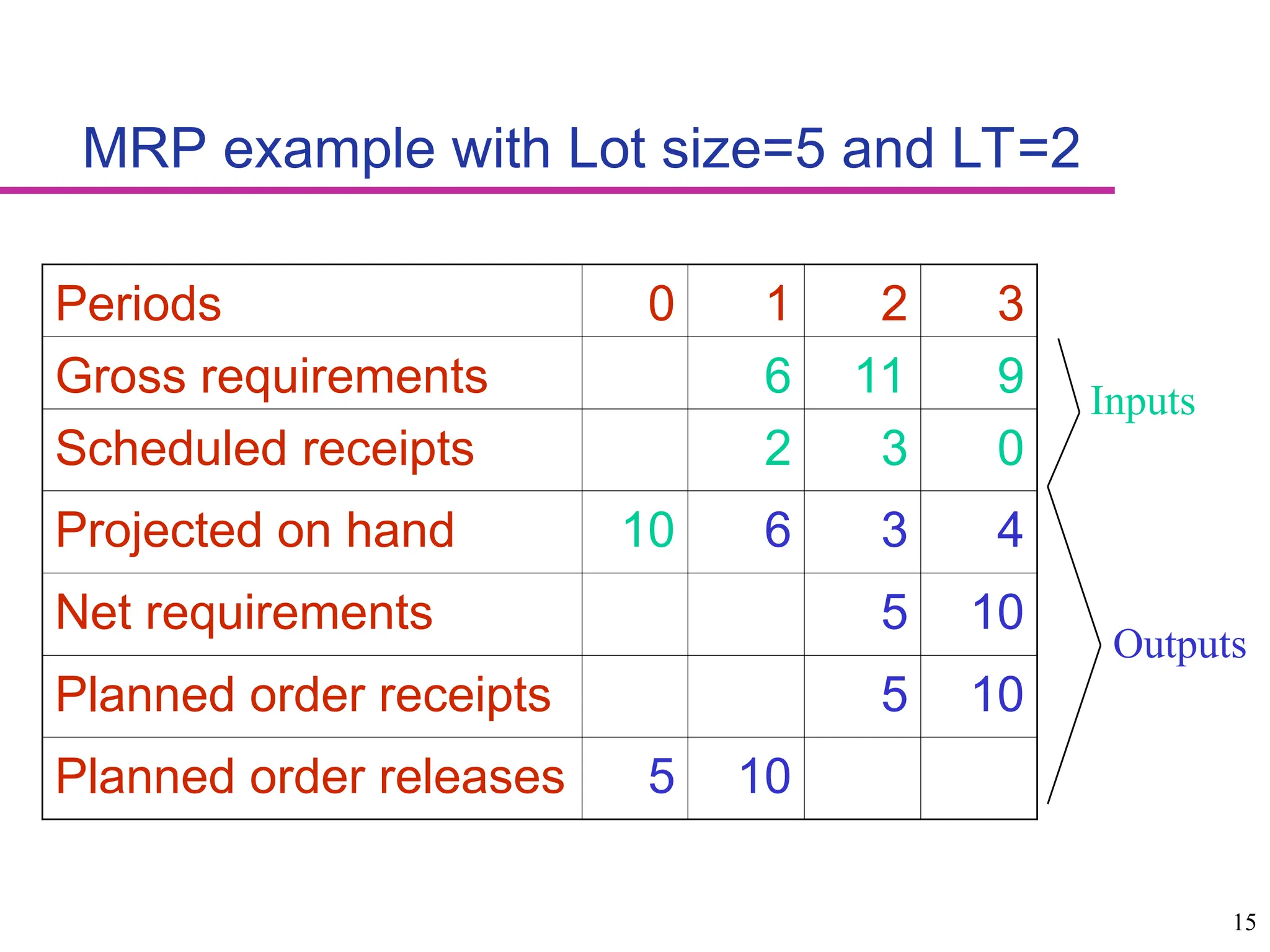

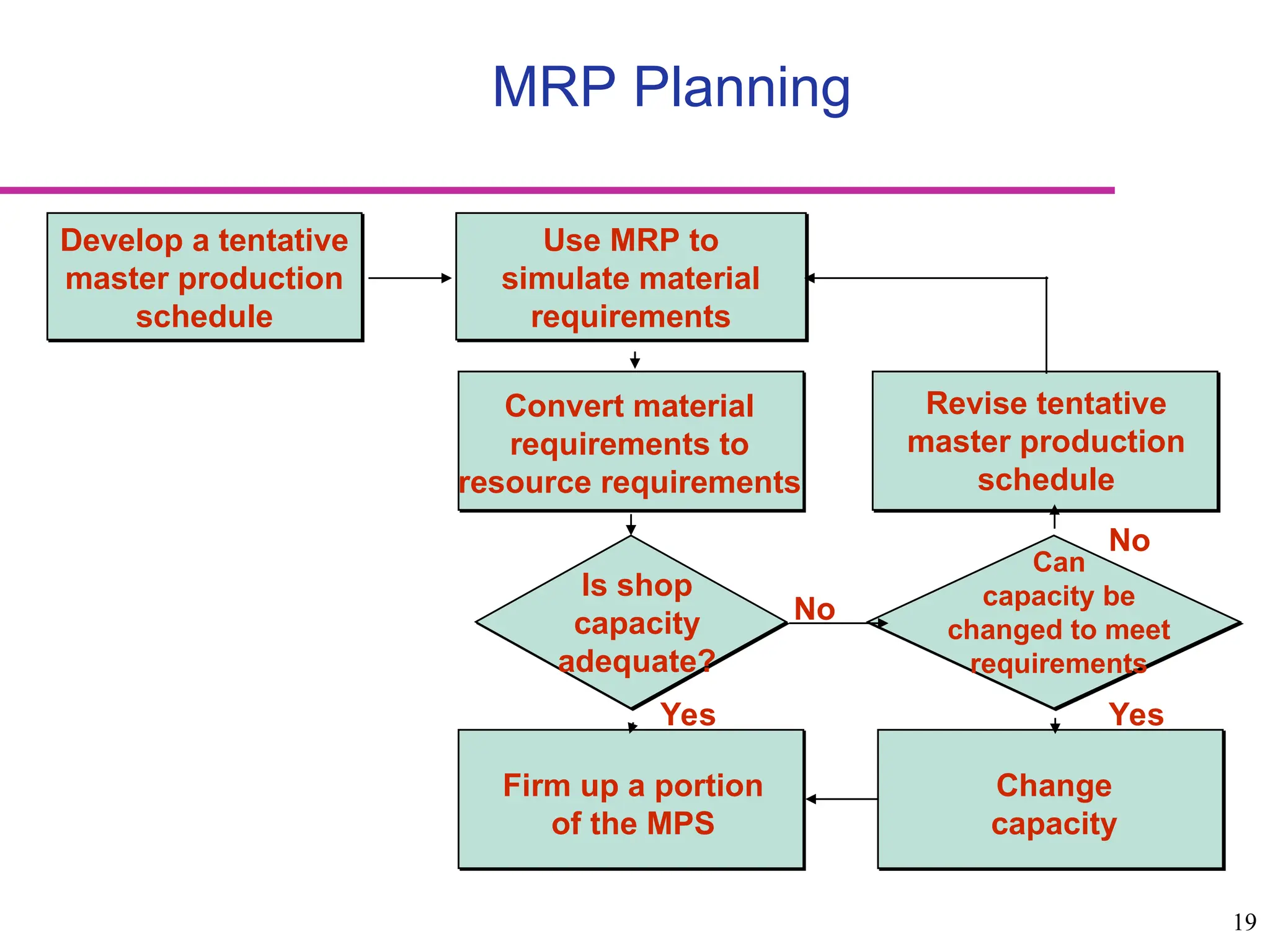

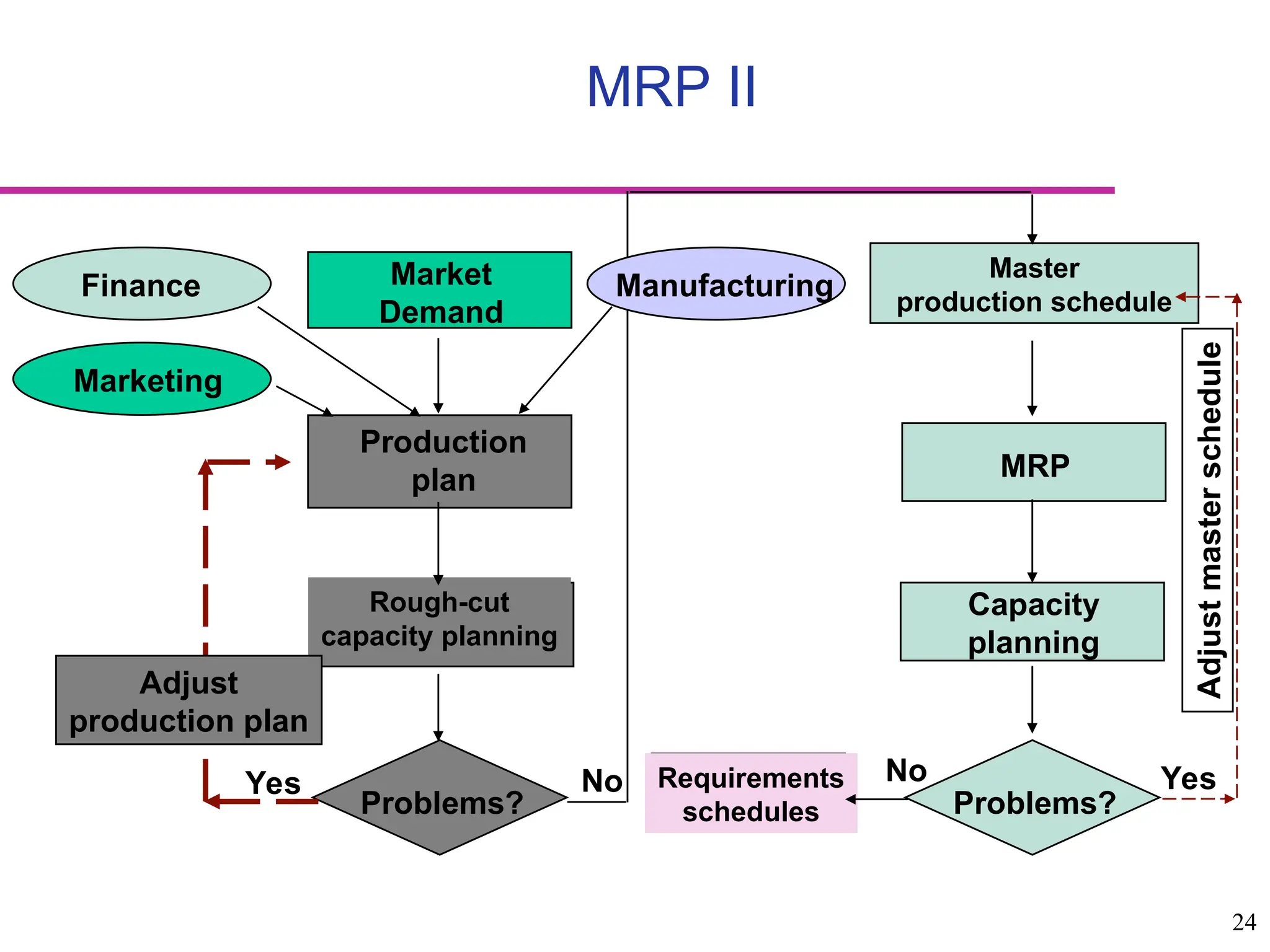

The document discusses Material Requirements Planning (MRP) and its role in managing dependent demand for products in manufacturing. It outlines key inputs like the master production schedule and bill of materials, processing methods for calculating requirements, and the importance of capacity planning. Additionally, it highlights the benefits and requirements of MRP, alongside the concept of Enterprise Resource Planning (ERP) for broader organizational integration.