This document provides information on Material Requirements Planning (MRP), including:

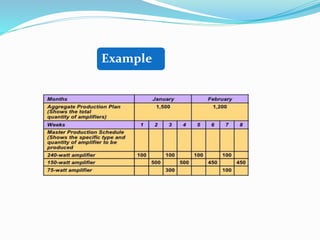

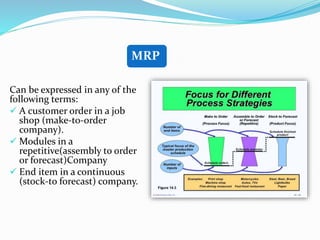

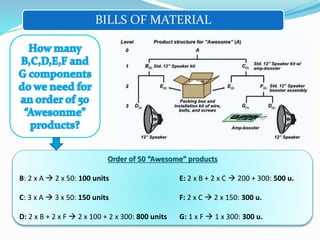

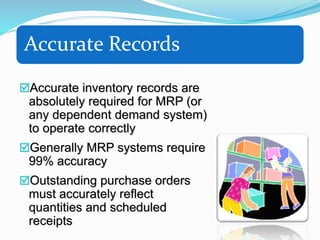

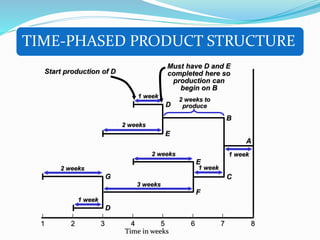

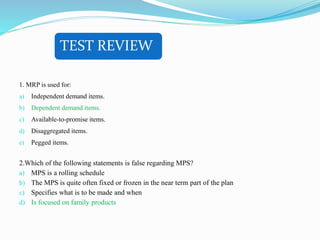

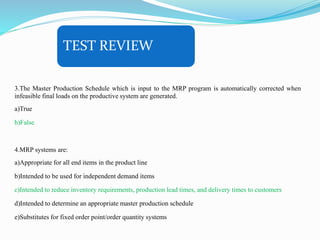

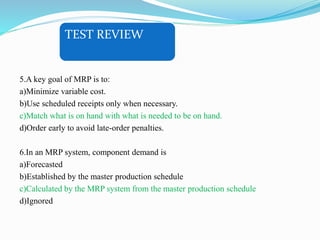

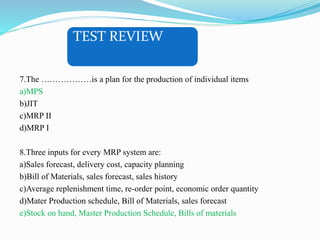

- MRP is a technique used to determine material requirements based on a bill of materials, inventory levels, expected receipts, and a master production schedule.

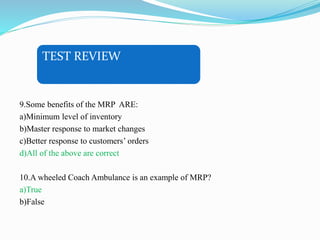

- The goal of MRP is to ensure materials and products are available when needed while maintaining low inventory levels.

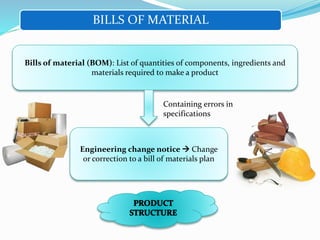

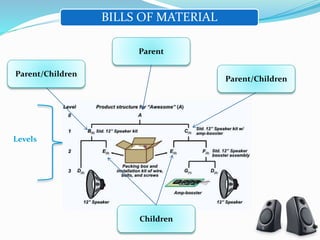

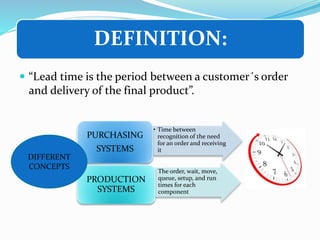

- Key inputs to an MRP system include a bill of materials, inventory data, a master production schedule, and lead times. MRP then calculates component requirements based on the schedule.