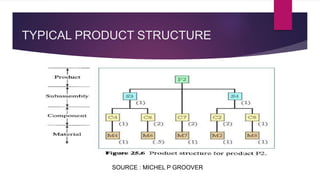

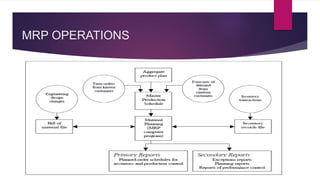

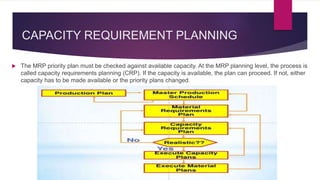

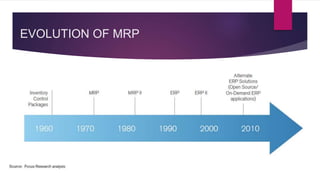

Material Requirement Planning (MRP) is a time-phased priority-planning technique developed by Joseph Orlicky in 1964 for managing manufacturing processes, scheduling supply, and controlling inventory. It involves managing orders based on independent and dependent demands to ensure material availability while minimizing excess. MRP systems vary in implementation levels (A to D) and can help forecast materials, reduce waste, and improve production efficiency, though they may suffer from inaccuracies and setup costs.