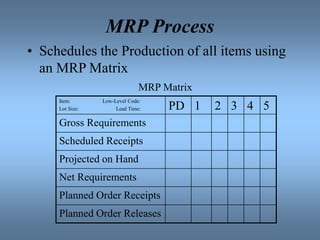

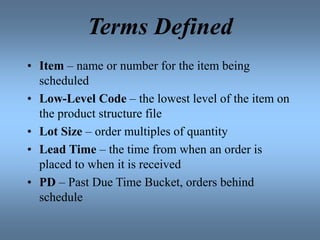

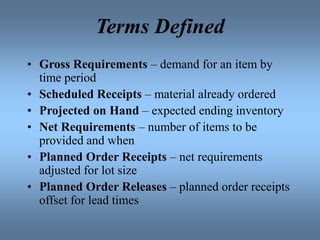

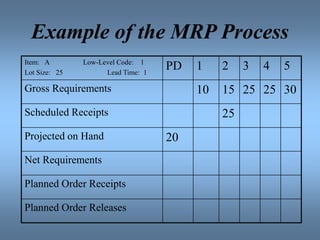

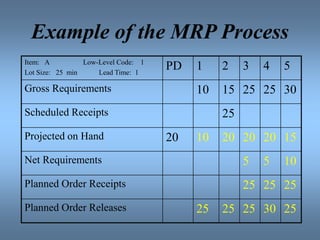

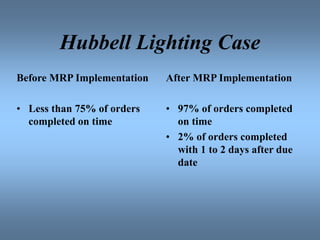

MRP is a computerized inventory control and production planning system that schedules component items as needed. It tracks inventory and helps companies in many aspects of business, such as reducing inventory levels and improving customer service. MRP takes inputs like a product structure file and master production schedule to output manufacturing and purchasing orders. It works by identifying material requirements through a multi-step process of gross requirements, scheduled receipts, and planned order releases. An example case showed how MRP helped a lighting manufacturer improve on-time order completion from less than 75% to 97%.