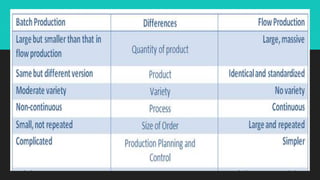

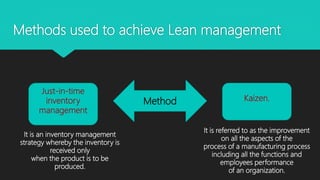

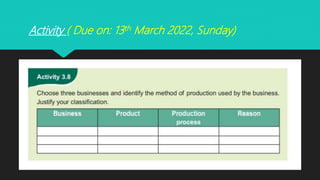

This document summarizes three common methods of production: job production, batch production, and flow production. It explains that job production involves manual production of unique products on a made-to-order basis. Batch production involves producing set quantities of goods together in batches before starting the next batch. Flow production is high-volume mass production of standardized items on a continuous basis. It also discusses the differences between batch and flow production, why businesses hold inventories, and the concept of lean production which aims to maximize value through eliminating waste.