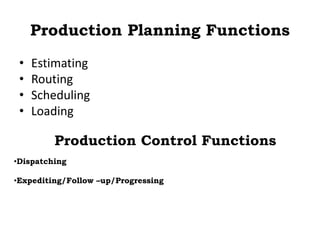

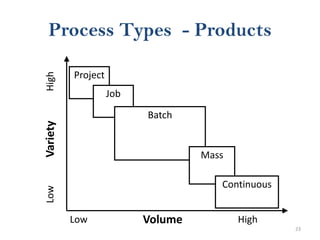

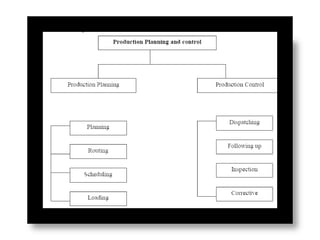

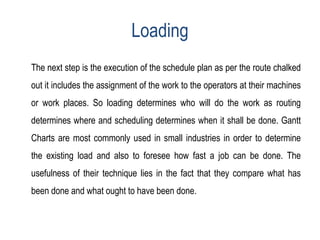

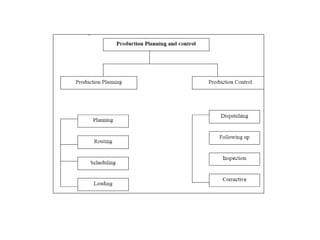

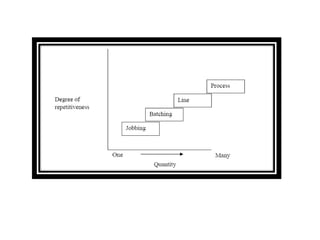

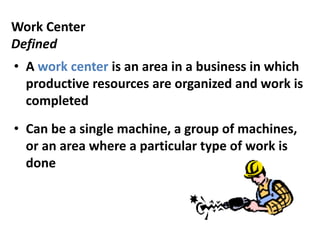

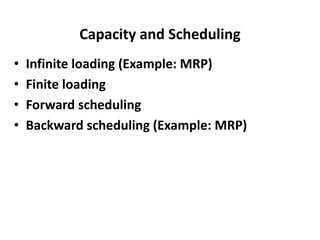

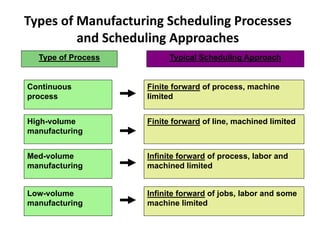

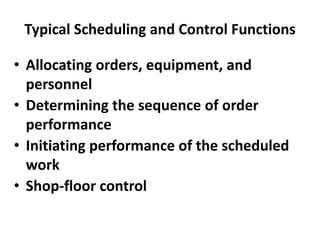

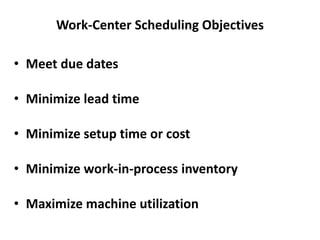

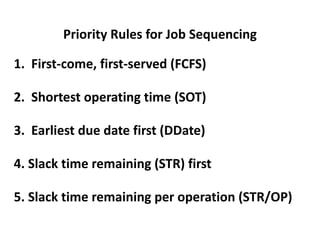

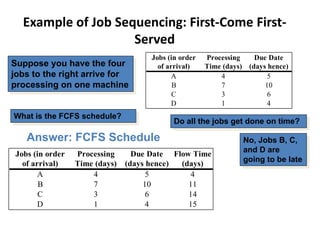

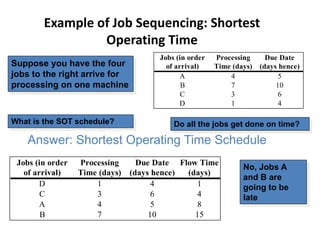

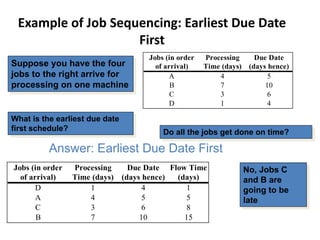

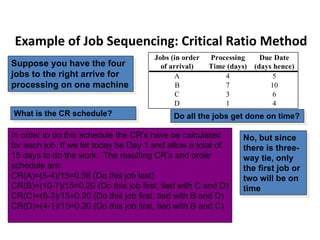

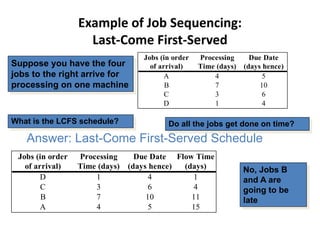

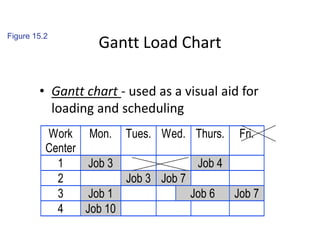

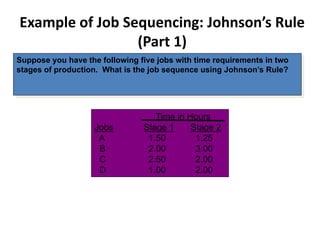

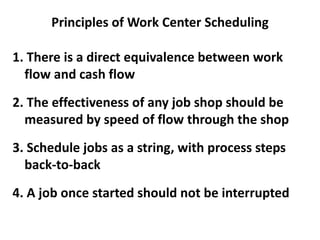

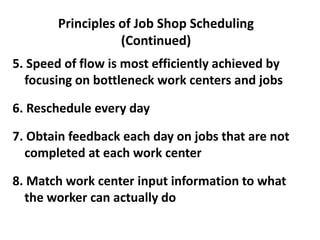

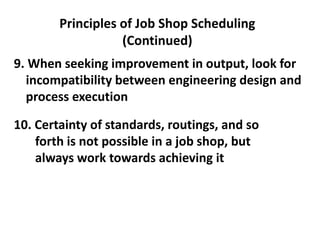

The document discusses production planning and control functions including process planning, loading, scheduling, dispatching, and follow up. It explains that process planning determines the sequence of operations, loading assigns work to work centers based on schedules, and scheduling determines start and finish times of operations. Dispatching authorizes the start of operations and follow up monitors progress. The document also covers factors that affect production planning like type of product and manufacturing. Different planning functions are needed for job shops, batch production, and mass production. Finally, it discusses scheduling objectives like meeting due dates and maximizing resource utilization.